Preparation method of in-situ electrifying type indium arsenide/gallium antimonide superlattice semiconductor sample of transmission electron microscope

A transmission electron microscope sample and transmission electron microscope technology, applied in the preparation of test samples, etc., can solve the problems of low hardness and high difficulty in preparation of transmission electron microscope samples, and achieve the effect of huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

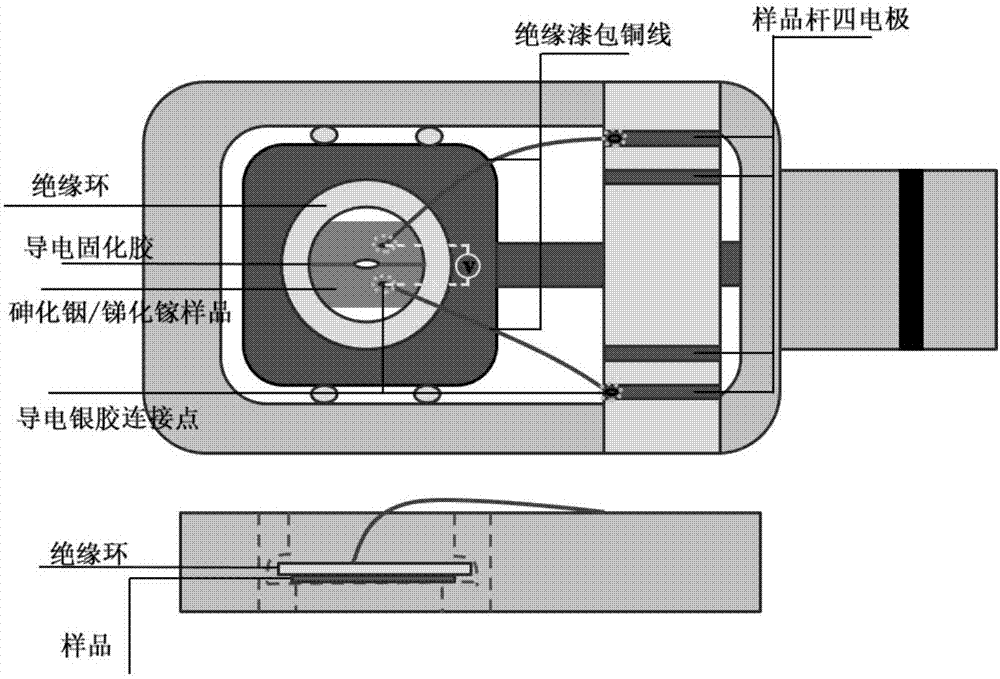

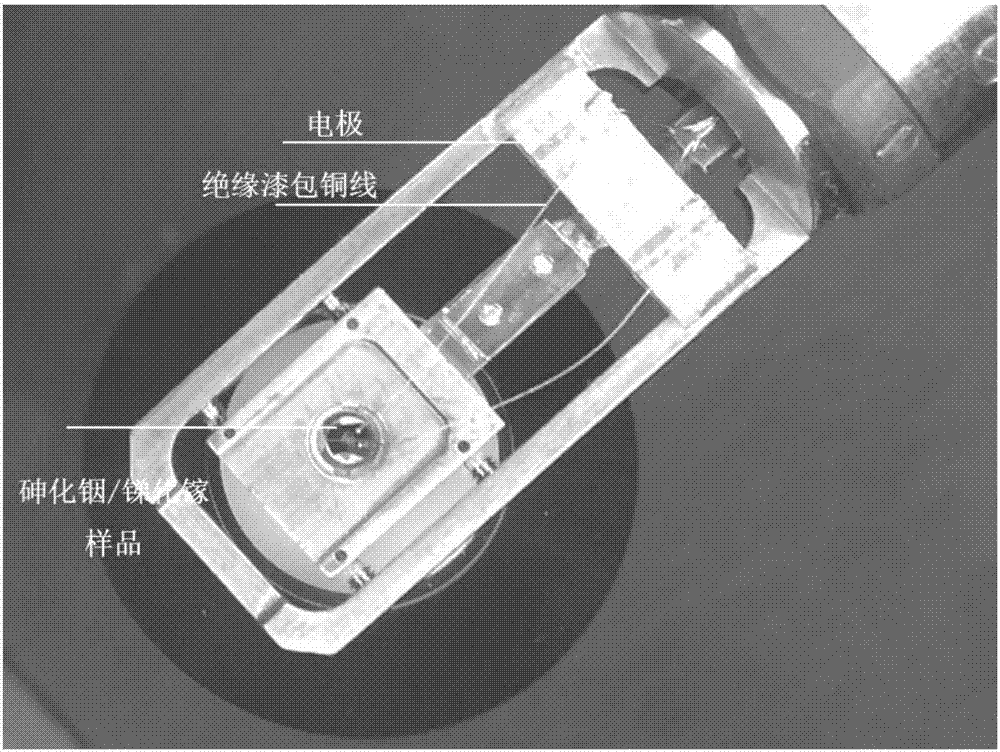

Method used

Image

Examples

Embodiment Construction

[0027] (1) Preparation of high temperature curing conductive silver glue

[0028] First, take the resin (Resin) and the curing agent (Hardender) in the commercial high-temperature curing glue, and mix them well at room temperature according to the ratio of 10:1~9:1; take an appropriate amount of commercial conductive silver glue according to the size of the sample, and mix with A small amount of high-temperature curing adhesive should be fully mixed according to the ratio of 3:1~3:2 for further use. It is worth noting that the prepared high-temperature curing conductive silver adhesive should be used as soon as possible, and should not exceed 24 hours at room temperature.

[0029] (2) TEM sample preparation of superlattice semiconductors

[0030] First, use a diamond knife to cut the bulk material into strips with a width of about 4-5 mm along the cleavage plane of the gallium antimonide substrate on which the superlattice semiconductor bulk material is grown, and then use a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com