A kind of high temperature chain oil and preparation method thereof

A high-temperature chain, high-temperature antioxidant technology, applied in the field of lubricating oil, can solve the problems of burning inverter or motor, high-temperature volatilization loss of chain oil, short coking cycle, etc., achieving excellent low-temperature stability, outstanding high-temperature stability, The effect of long coking cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0035] A preparation method of high temperature chain oil, comprising the steps:

[0036] Step 1: prepare synthetic base oil according to the weight ratio of PAO10:PAO 180I=66:25;

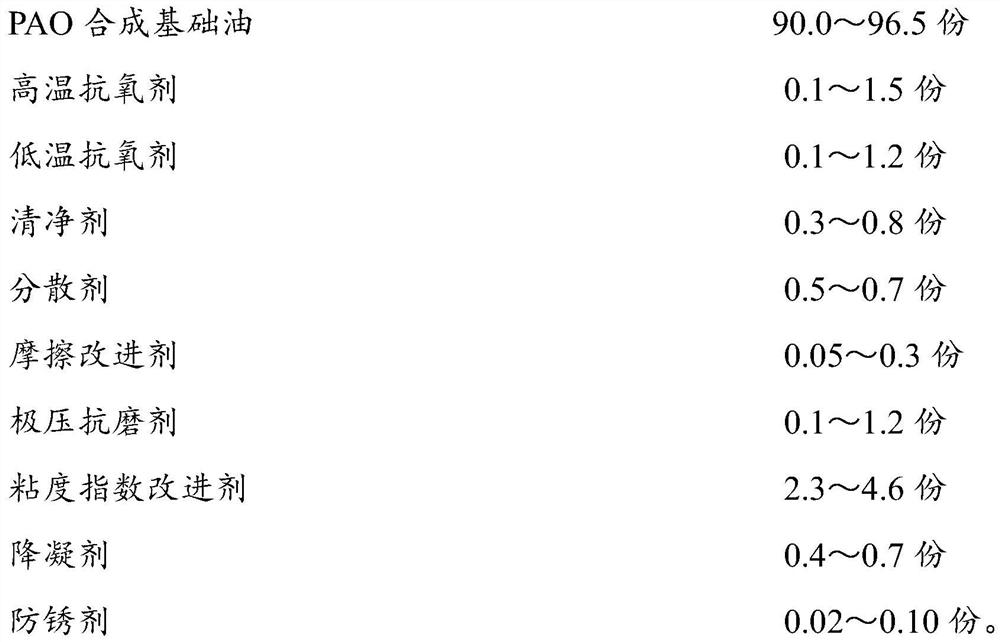

[0037] Step 2: Weigh each component according to the following parts by weight:

[0038]

[0039] Step 3: add synthetic base oil into the reactor, stir and heat to 70°C;

[0040] Step 4: Put pour point depressant and viscosity index improver into the reaction kettle at one time, and stir for 40 minutes at 300r / min.

[0041] Step 5: Continue to put high temperature antioxidant, low temperature antioxidant, detergent, dispersant, friction modifier and extreme pressure antiwear agent into the reaction kettle, and stir for 100 minutes at 350r / min;

[0042] Step 6: finally put the rust inhibitor into the reaction kettle and stir for 90 minutes at a rotating speed of 150r / min;

[0043] Step 7: The material in the reaction kettle is transported to a storage tank and allowed to stand for 120 minutes ...

no. 2 Embodiment

[0047] A preparation method of high temperature chain oil, comprising the steps:

[0048] Step 1: prepare synthetic base oil according to the weight ratio of PAO10:PAO 180I=68:24;

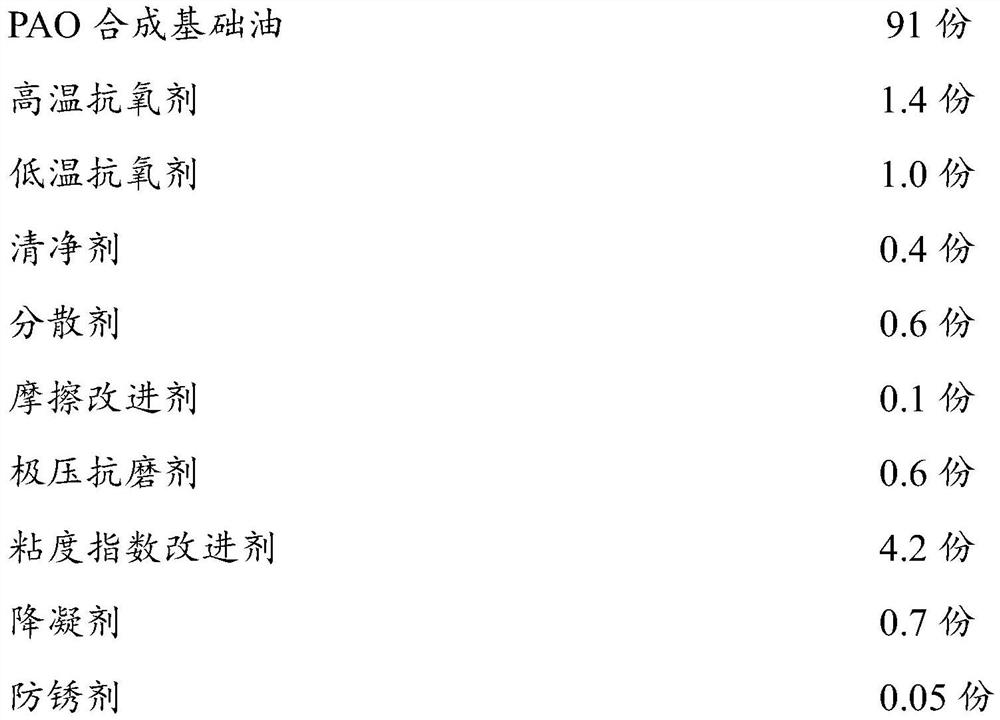

[0049] Step 2: Weigh each component according to the following parts by weight:

[0050]

[0051] Step 3: add synthetic base oil into the reactor, stir and heat to 70°C;

[0052] Step 4: Put pour point depressant and viscosity index improver into the reaction kettle at one time, and stir for 40 minutes at 300r / min.

[0053]Step 5: Continue to put high temperature antioxidant, low temperature antioxidant, detergent, dispersant, friction modifier and extreme pressure antiwear agent into the reaction kettle, and stir for 100 minutes at 300r / min;

[0054] Step 6: finally put the rust inhibitor into the reaction kettle, and stir for 90 minutes at a rotating speed of 200r / min;

[0055] Step 7: The material in the reaction kettle is transported to a storage tank and allowed to stand for 120 minutes ...

no. 3 Embodiment

[0058] A preparation method of high temperature chain oil, comprising the steps:

[0059] Step 1: prepare synthetic base oil according to the weight ratio of PAO10:PAO 180I=67:26;

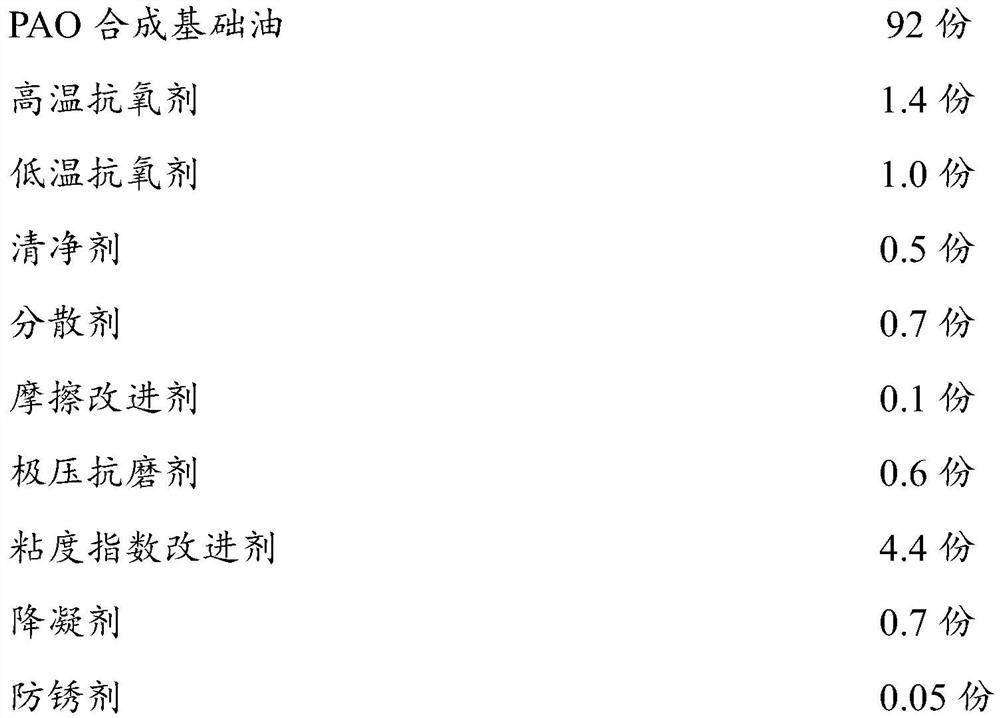

[0060] Step 2: Weigh each component according to the following parts by weight:

[0061]

[0062] Step 3: add synthetic base oil into the reactor, stir and heat to 70°C;

[0063] Step 4: Put pour point depressant and viscosity index improver into the reaction kettle at one time, and stir for 40 minutes at 300r / min.

[0064] Step 5: Continue to put high temperature antioxidant, low temperature antioxidant, detergent, dispersant, friction modifier and extreme pressure antiwear agent into the reaction kettle, and stir for 100 minutes at 400r / min;

[0065] Step 6: finally put the rust inhibitor into the reaction kettle and stir for 90 minutes at a rotating speed of 100r / min;

[0066] Step 7: The material in the reaction kettle is transported to a storage tank and allowed to stand for 120 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com