A kind of organosilicon super-weather-resistant anti-cracking anti-corrosion coating

An anti-corrosion coating and silicone technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as strong corrosion, coating cracks, environmental pollution, etc., and achieve the effects of convenient and safe construction, excellent weather resistance, and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

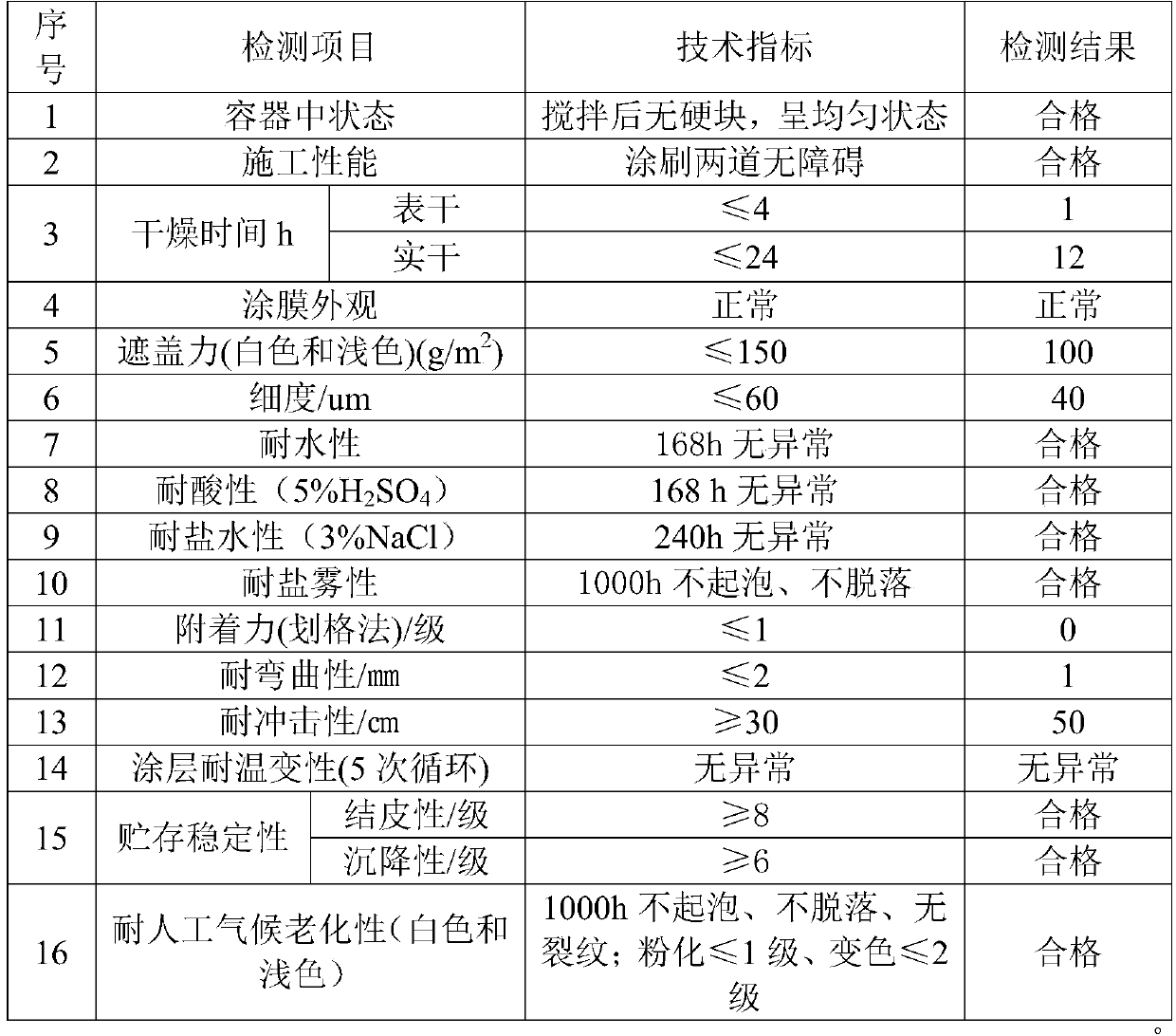

Examples

Embodiment 1

[0036] An organosilicon super-weather-resistant anti-cracking anti-corrosion coating, its raw materials are composed of: organosilicon elastic resin: 100 parts, surface-treated fumed silica powder: 10 parts, surface-treated rutile TiO 2 : 15 parts, zinc phosphate: 10 parts, aluminum tripolyphosphate: 15 parts, precipitated barium sulfate: 5 parts, mica powder: 5 parts, talcum powder: 2 parts, glass fiber: 10 parts, hydroxy silicone oil: 15 parts, pigment (Iron red pigment): 1 part, crosslinking agent (methyl tributyl ketoxime silane): 3 parts, coupling agent (γ-aminopropyl triethoxysilane): 0.5 part, catalyst (dilauric dibutyltin acid): 0.05 parts.

[0037] The silicone elastic resin is formed by copolymerization of low-viscosity α, ω-dihydroxypolydimethylsiloxane, diphenyldihydroxysilane and orthosilicate with a viscosity below 5000cs. The low-viscosity α, ω- The molar ratio of dihydroxypolydimethylsiloxane, diphenyldihydroxysilane and ethyl orthosilicate is 5:1:2, using iso...

Embodiment 2

[0042] A kind of organosilicon super-weather-resistant anti-cracking anti-corrosion coating, its raw material is composed of: organosilicon elastic resin: 100 parts, surface-treated fumed silica powder: 15 parts, surface-treated rutile TiO 2 : 10 parts, zinc phosphate: 15 parts, aluminum tripolyphosphate: 12 parts, precipitated barium sulfate: 4 parts, mica powder: 8 parts, talcum powder: 4 parts, glass fiber: 7 parts, hydroxy silicone oil: 18 parts, pigment (Carbon black pigment): 6 parts, crosslinking agent (3 parts of methyl tributylketoxime silane + 4 parts of phenyl tributylketoxime silane): 7 parts, coupling agent (γ-glycidyl ether oxygen Propyltrimethoxysilane): 1.5 parts, catalyst (dioctyltin dilaurate): 0.07 parts.

[0043] The silicone elastic resin is formed by copolymerization of low-viscosity α, ω-dihydroxypolydimethylsiloxane, diphenyldihydroxysilane and orthosilicate with a viscosity below 5000cs. The low-viscosity α, ω- The molar ratio of dihydroxypolydimethyl...

Embodiment 3

[0048] A kind of organosilicon super-weather-resistant anti-cracking anti-corrosion coating, its raw material is composed of: organosilicon elastic resin: 100 parts, surface-treated fumed silica powder: 20 parts, surface-treated rutile TiO 2 : 5 parts, zinc phosphate: 20 parts, aluminum tripolyphosphate: 10 parts, precipitated barium sulfate: 3 parts, mica powder: 10 parts, talc powder: 5 parts, glass fiber: 5 parts, hydroxy silicone oil: 20 parts, pigment (cobalt blue pigment): 10 parts, crosslinking agent (3 parts of tetrabutylketoxime silane + 7 parts of phenyl tributylketoxime silane): 10 parts, coupling agent (γ-glycidyl ether oxypropyl 1 part of trimethoxysilane+1 part of γ-methacryloxypropyltrimethoxysilane): 2 parts, catalyst (dibutyltin diacetate): 0.1 part.

[0049] The silicone elastic resin is formed by copolymerization of low-viscosity α, ω-dihydroxypolydimethylsiloxane, diphenyldihydroxysilane and orthosilicate with a viscosity below 5000cs. The low-viscosity α, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| salt spray resistance time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com