Anti-fouling substrate and preparation method thereof

A substrate and anti-fouling technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of poor sample surface wear resistance, difficulty in maintaining the original appearance of the sample surface, and poor surface wear resistance. Solve the effect of poor surface wear resistance, precise and controllable size, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

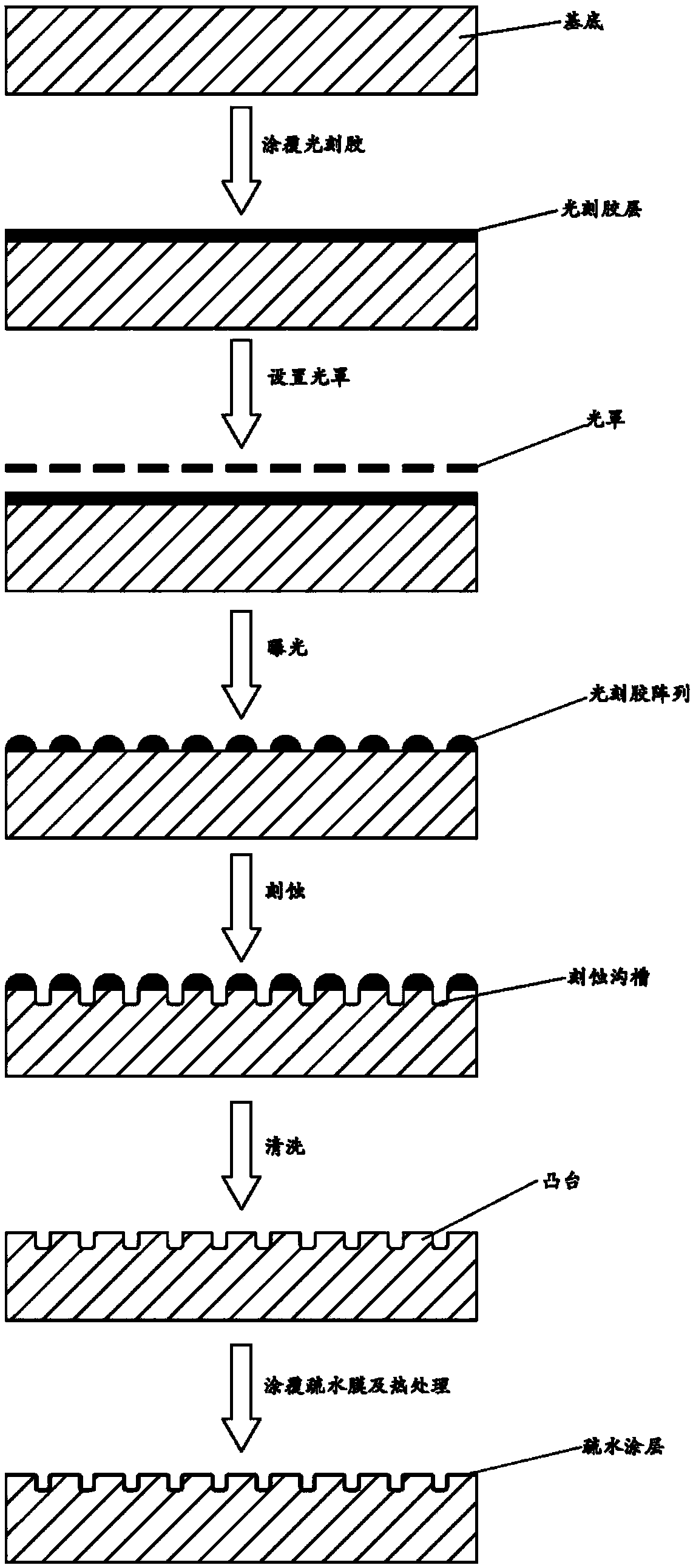

[0043] attached figure 1 It is a flowchart of an embodiment of the preparation method of the anti-fouling substrate of the present invention, specifically, the preparation method of the anti-fouling substrate of the present invention includes the following steps:

[0044] (1), coating a layer of photoresist on the surface of the zirconia substrate;

[0045] (2), the base that step (1) gained is coated with photoresist carries out deep ultraviolet exposure treatment under different photomasks, forms photoresist array;

[0046] (3), etch the base template after the exposure treatment obtained in step (2), and then clean the etched base template to obtain a base with a boss;

[0047] (4), coating the substrate with bosses obtained in step (3) with a hydrophobic material;

[0048] (5) Heat-treating the substrate coated with the hydrophobic material to obtain the antifouling substrate.

Embodiment 1

[0051] An embodiment of the antifouling substrate of the present invention, the base material of the antifouling substrate is zirconia, the coating is perfluorodecyltriethoxysilane, the average height of the bosses is 120nm, each The average upper surface area of the boss is 1.767×10 4 nm 2 , the average spacing between adjacent bosses is 150nm.

[0052] The preparation method of the antifouling substrate described in this embodiment comprises the following steps:

[0053] (1), clean the zirconia substrate with a cleaning agent, then clean it with ultrasonic waves for 5 minutes, and then clean it with deionized water for 2 minutes;

[0054] (2) Coating the photoresist on the zirconia substrate by spin coating with a coating thickness of 0.8 μm, and then baking at 100° C. for 1 min;

[0055] (3), the substrate coated with photoresist obtained in step (2) is subjected to exposure treatment using a grating;

[0056] (4), adopt reactive ion etching to the substrate of step (...

Embodiment 2

[0060] An embodiment of the antifouling substrate of the present invention, the base material of the antifouling substrate is zirconia, the coating is perfluorodecyltriethoxysilane, the average height of the bosses is 120nm, each The average upper surface area of the boss is 1.767×10 4 nm 2 , the average spacing between adjacent bosses is 150nm.

[0061] The preparation method of the antifouling substrate described in this embodiment comprises the following steps:

[0062] (1), clean the zirconia substrate with a cleaning agent, then clean it with ultrasonic waves for 5 minutes, and then clean it with deionized water for 2 minutes;

[0063] (2) Coating the photoresist on the zirconia substrate by spin coating with a coating thickness of 0.8 μm, and then baking at 100° C. for 1 min;

[0064] (3), the substrate coated with photoresist obtained in step (2) is exposed to deep ultraviolet light, the photomask is a circular array with a period of 150nm, and exposed to deep ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com