Welding flux for X70 pipeline steel longitudinal submerged arc welding and preparation method of welding flux

A technology of straight seam submerged arc welding and pipeline steel, applied in arc welding equipment, welding equipment, welding equipment, etc., to achieve the effect of reducing labor intensity, improving one-time pass rate, and good low-temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of preparation method of above-mentioned X70 pipeline steel straight seam submerged arc welding flux, described steps are as follows:

[0021] (1) Raw material preparation, MnO, GaF, Al2O3, MgO, SiFe raw materials with good quality and high purity;

[0022] (2) Processing the raw materials in step (1) into 100-mesh fine powder respectively to obtain the raw material fine powder;

[0023] (3) Weigh out the raw material fine powder prepared in step (2) according to the formula and mix evenly to obtain the mixed raw material;

[0024] (4) Adding the mixed raw material prepared in step (3) into sodium silicate and stirring to obtain millet-shaped granules;

[0025] (5) drying the semi-solid raw material prepared in step (4), and controlling the moisture content within 5% after drying;

[0026] (6) Sintering, heat the flux dried in step (5) at a temperature of 790-810 degrees for 90-110 minutes;

[0027] (7) Pass the flux sintered in step (6) through a 10-26 mesh s...

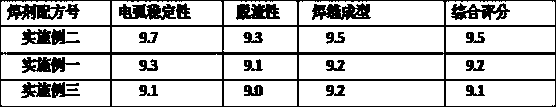

Embodiment 1

[0029] A kind of flux for straight seam submerged arc welding of X70 pipeline steel, the chemical formula of described flux comprises MnO9wt.%, GaF20wt.%, Al 2 0 3 20 wt.%, MgO32 wt.%, siFeO.9 wt.%.

[0030] The above-mentioned flux for linear submerged arc welding of X70 pipeline steel, the basicity of the flux for linear submerged arc welding of X70 pipeline steel is 1.2.

[0031] A preparation method of flux for X70 pipeline steel longitudinal submerged arc welding as described above, the steps are as follows:

[0032] (1) Prepare raw materials, prepare high-quality MnO, GaF, Al203, MgO, SiFe raw materials;

[0033] (2) Processing the raw materials in step (1) into 100-mesh fine powder respectively to obtain the raw material fine powder;

[0034] (3) Weigh out the raw material fine powder prepared in step (2) according to the formula and mix evenly to obtain the mixed raw material;

[0035] (4) Adding the mixed raw material prepared in step (3) into sodium silicate and ...

Embodiment 2

[0040] A kind of flux for straight seam submerged arc welding of X70 pipeline steel, the chemical formula of described flux comprises MnO10wt.%, GaF25wt.%, Al 2 0 3 23wt.%, MgO36 wt.%, siFe1.05 wt.%.

[0041] For the X70 pipeline steel longitudinal submerged arc welding flux described above, the basicity of the X70 pipeline steel longitudinal submerged arc welding flux is 1.4.

[0042] A preparation method of flux for X70 pipeline steel longitudinal submerged arc welding as described above, the steps are as follows:

[0043] (1) Prepare raw materials, prepare high-quality MnO, GaF, Al203, MgO, SiFe raw materials;

[0044] (2) Processing the raw materials in step (1) into 100-mesh fine powder respectively to obtain the raw material fine powder;

[0045] (3) Weigh out the raw material fine powder prepared in step (2) according to the formula and mix evenly to obtain the mixed raw material;

[0046] (4) Adding the mixed raw material prepared in step (3) into sodium silicate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com