Flaw detection process for finished offshore wind power large balls

An offshore wind power and process technology, which is applied in the field of finished offshore wind power large ball flaw detection technology, can solve the problems of long processing and inspection cycle, large ball mass, and large impact force, so as to reduce manual labor, ensure inspection results, and shorten inspection cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

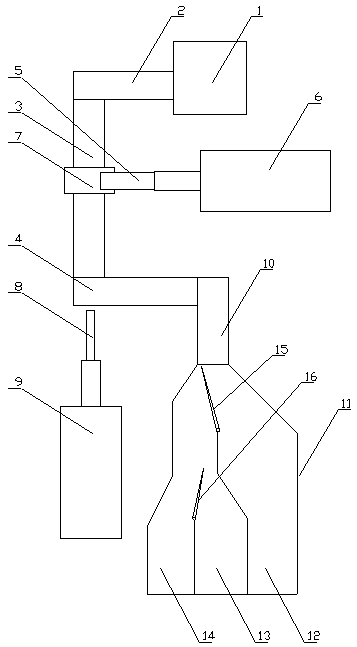

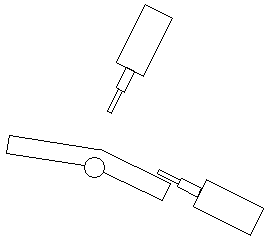

[0019] like figure 1 , figure 2 As shown, the finished offshore wind power large ball flaw detection process of the present invention is realized through the following steps:

[0020] The first step, steel ball preparation: firstly, all the steel balls to be tested are placed in the upper ball rack 1 .

[0021] The second step, steel ball conveying: the steel ball sent from the discharge end of the upper ball rack 1 is conveyed by the conveying alley. It is a segmented structure, including the scoring section 2, the detection section 3 and the ball delivery section 4 arranged in sequence, and the planes where the goal section 2 and the ball delivery section 4 are located are parallel to each other, and the planes where the goal section 2 and the detection section 3 are l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com