Vacuum pump system combining three stages of booster pumps and water ring pumps

A technology of water ring pump and booster pump, which is used in pumps, pump devices, liquid variable capacity machinery, etc., to achieve the effects of low steam consumption, cost reduction and flexibility enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

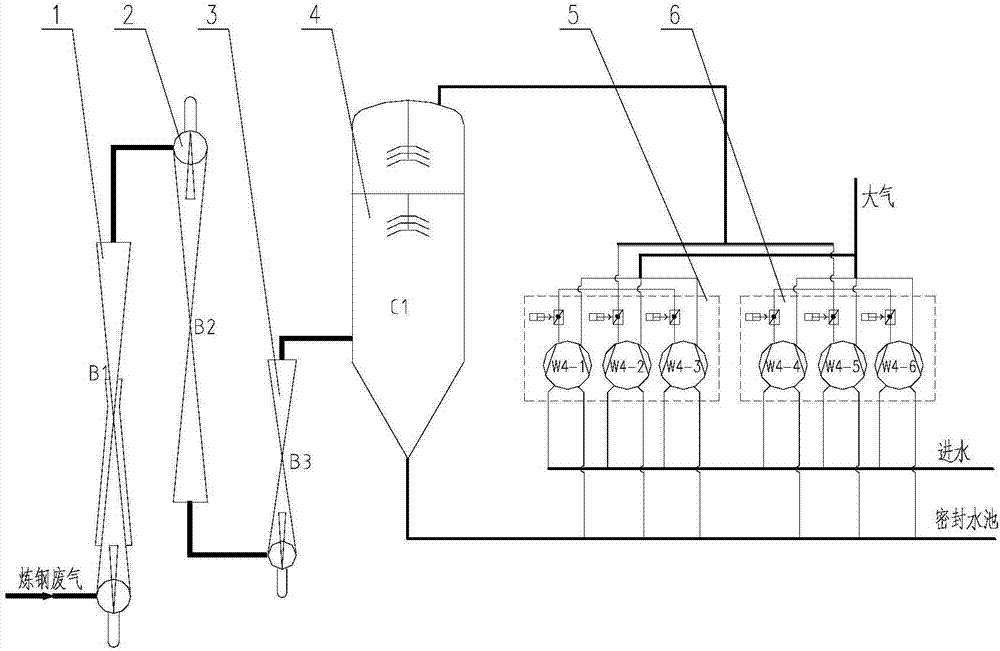

[0018] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

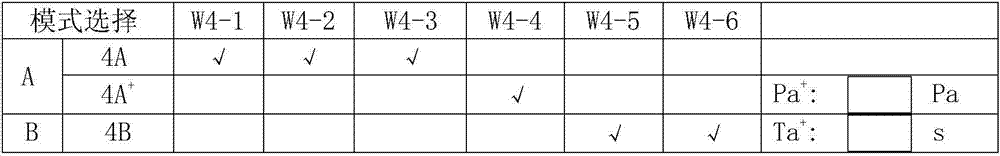

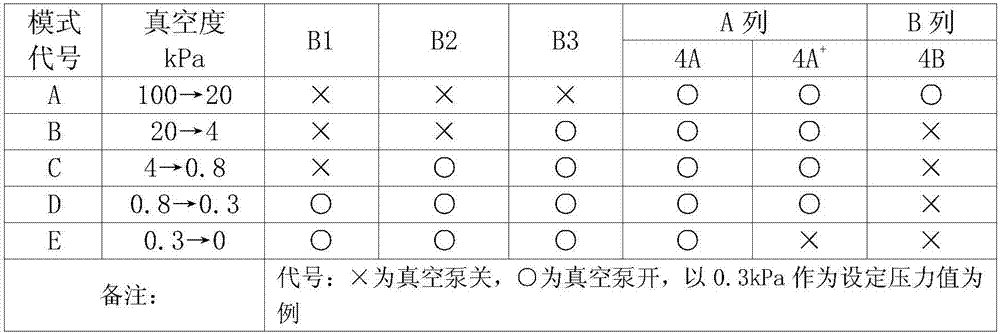

[0019] Such as figure 1 Shown: a vacuum pump system configuration model of a combination of water ring pump and steam pump, including B1 booster pump 1, B2 booster pump 2, B3 booster pump 3, C1 condenser 4 and water ring pump unit, B1 booster Pump 1, B2 booster pump 2, and B3 booster pump 3 are connected in series through the air extraction pipeline. The inlet of B1 booster pump 1 is connected with the waste gas generated in the steelmaking process, and the outlet of B3 booster pump 3 is connected with C1 Condenser 4 Unicom. A suction pipe is connected from the top of the C1 condenser 4 and connected to two parallel water ring pump units. The exhaust ports of each water ring pump are converged and connected to an exhaust pipe, and then communicated with the exhaust gas outlet. Corresponding control valves are set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com