Preparation method of adhesive plastering piece with rapid solidification and easy storage

A technology of rapid curing and lamination, applied in the field of electronic adhesives, to achieve the effect of small viscosity changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

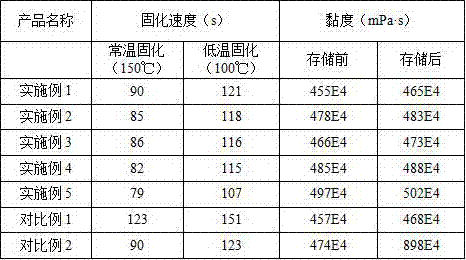

Examples

Embodiment 1

[0015] A method for preparing a fast-curing and easy-to-storage film, comprising the following steps: (1) Weighing the following components by weight: 40 parts of epoxy resin, N-2-methylimidazole-N'-(P-cyanophenyl ) 8 parts of urea, 0.5 parts of dicyandiamide, 0.5 parts of aminated lignin, 0.5 parts of benzyl dimethylamine, 2.5 parts of ethylene glycol diglycidyl ether, 0.6 parts of 1,4-butanediol glycidyl ether, pentaerythritol 5 parts of glycidyl ether, 8 parts of mercaptan end-group liquid nitrile rubber, 0.5 part of nano-calcium carbonate, 0.1 part of polyethylene wax, and 0.1 part of pigment; (2) Mix N-2-methylimidazole with a planetary power mixer -N'-(P-cyanophenyl)urea, dicyandiamide, aminated lignin and epoxy resin are mixed, and ground twice by three-roller machine to obtain a mixed paste; (3) Add Benzyldimethylamine, ethylene glycol diglycidyl ether, 1,4-butanediol glycidyl ether, pentaerythritol glycidyl ether, polyethylene wax, control the temperature at 75°C, sti...

Embodiment 2

[0017] A method for preparing a fast-curing and easy-to-storage film, comprising the following steps: (1) Weighing the following components by weight: 65 parts of epoxy resin, N-2-methylimidazole-N'-(P-cyanophenyl ) 2 parts of urea, 6 parts of dicyandiamide, 6 parts of aminated lignin, 5 parts of benzyl dimethylamine, 7 parts of ethylene glycol diglycidyl ether, 5 parts of 1,4-butanediol glycidyl ether, pentaerythritol 2 parts of glycidyl ether, 1 part of liquid nitrile rubber with mercaptan end group, 6 parts of nano-calcium carbonate, 5 parts of polyethylene wax, and 1 part of pigment; (2) Mix N-2-methylimidazole in a planetary power mixer -N′-(P-cyanophenyl) urea, dicyandiamide, aminated lignin and epoxy resin are mixed, and ground by three-roll machine for 5 times to obtain a mixed paste; (3) Add Benzyldimethylamine, ethylene glycol diglycidyl ether, 1,4-butanediol glycidyl ether, pentaerythritol glycidyl ether, polyethylene wax, control the temperature at 90°C, stir until...

Embodiment 3

[0019] A method for preparing a fast-curing and easy-to-storage film, comprising the following steps: (1) Weighing the following components by weight: 45 parts of epoxy resin, N-2-methylimidazole-N'-(P-cyanophenyl ) 4 parts of urea, 4 parts of dicyandiamide, 2.5 parts of aminated lignin, 2.5 parts of benzyl dimethylamine, 4.5 parts of ethylene glycol diglycidyl ether, 4.5 parts of 1,4-butanediol glycidyl ether, pentaerythritol 2.8 parts of glycidyl ether, 3 parts of liquid nitrile rubber with mercaptan end groups, 4.8 parts of nano-calcium carbonate, 1.5 parts of polyethylene wax, and 0.3 parts of pigment; (2) Mix N-2-methylimidazole with a planetary power mixer -N'-(P-cyanophenyl) urea, dicyandiamide, aminated lignin and epoxy resin are mixed, and ground by three-roll machine for 4 times to obtain a mixed paste; (3) Add Benzyldimethylamine, ethylene glycol diglycidyl ether, 1,4-butanediol glycidyl ether, pentaerythritol glycidyl ether, polyethylene wax, control the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com