Standard substance for carrying out micro-zone in-situ analysis on components of silicates and preparation method thereof

A standard material and in-situ analysis technology, applied in the direction of analysis of materials, preparation of test samples, material analysis through electromagnetic means, etc., can solve the problem that the minimum sampling volume of the analysis standard material cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

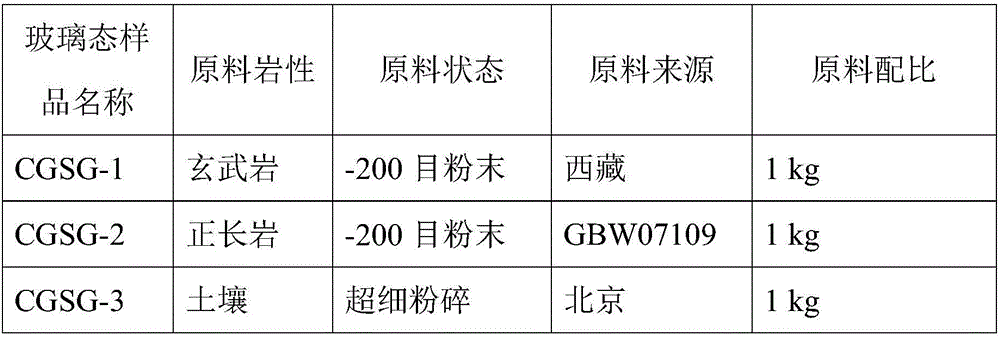

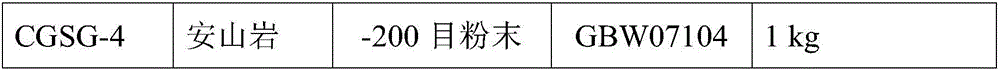

[0030] The standard material uses the basalt powder described in Table 1 as the base material, and after the base material is melted and annealed, a glass sample block is obtained, and the glass sample block is used as a standard material for laser ablation plasma mass spectrometry Perform micro-area in situ multi-element analysis.

[0031] The preparation method of this standard substance comprises the steps:

[0032] (1) Take 1 kg of basalt powder as the base material, add distilled water to the base material, the quality of the added distilled water accounts for 5% of the total mass of the base material and distilled water; In a corundum crucible at 1550°C for 7 hours, pour the melt into a water pool and quench to obtain slag with a particle size of less than 0.5mm;

[0033] (2) After cleaning the slag obtained in step (1) with distilled water, dry it at 200°C for 3 hours, then ball mill it in an agate ball mill for 3 hours, pass through a 100 mesh sieve, and filter out cl...

Embodiment 2

[0037] The standard substance uses the syenite powder described in Table 1 as the base material, and after the base material is melted and annealed, a glass sample block is obtained, and the glass sample block is used as a standard material for laser ablation plasma Mass spectrometry for in situ multi-element analysis of microregions.

[0038] The preparation method of this standard substance comprises the steps:

[0039] (1) Take 1kg syenite powder as the base material, add distilled water into the base material, the quality of the added distilled water accounts for 6% of the total mass of the base material and distilled water; then add the mixed product of the base material and distilled water to the preheating In a corundum crucible at 1350°C, melt at 1600°C for 6 hours, pour the melt into a water pool and quench to obtain slag with a particle size of less than 0.5mm;

[0040] (2) After cleaning the slag obtained in step (1) with distilled water, dry it at 150°C for 4 hour...

Embodiment 3

[0044] The standard material uses the soil powder described in Table 1 as the base material, and after the base material is melted and annealed, a glass sample block is obtained, and the glass sample block is used as a standard material for laser ablation plasma mass spectrometry Perform micro-area in situ multi-element analysis.

[0045] The preparation method of this standard substance comprises the steps:

[0046] (1) Take 1kg of soil powder as the base material, add distilled water into the base material, the quality of the added distilled water accounts for 8% of the total mass of the base material and distilled water; In a corundum crucible at 1570°C for 6 hours, pour the melt into a water pool and quench to obtain slag with a particle size of less than 0.5mm;

[0047] (2) After cleaning the slag obtained in step (1) with distilled water, dry it at 200°C for 2 hours, then ball mill it in an agate ball mill for 4 hours, pass through a 100 mesh sieve, and filter out clink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com