A kind of preparation method of silica airgel water-based thermal insulation coating

A technology for thermal insulation coatings and silica, applied in chemical instruments and methods, reflective/signal coatings, coatings, etc., can solve the problems of uneven particle size distribution, poor film formation, low porosity, etc. Thermal properties and finished product quality, improved film quality and stability, improved dispersion and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of silica airgel water-based thermal insulation coating, comprising the following steps:

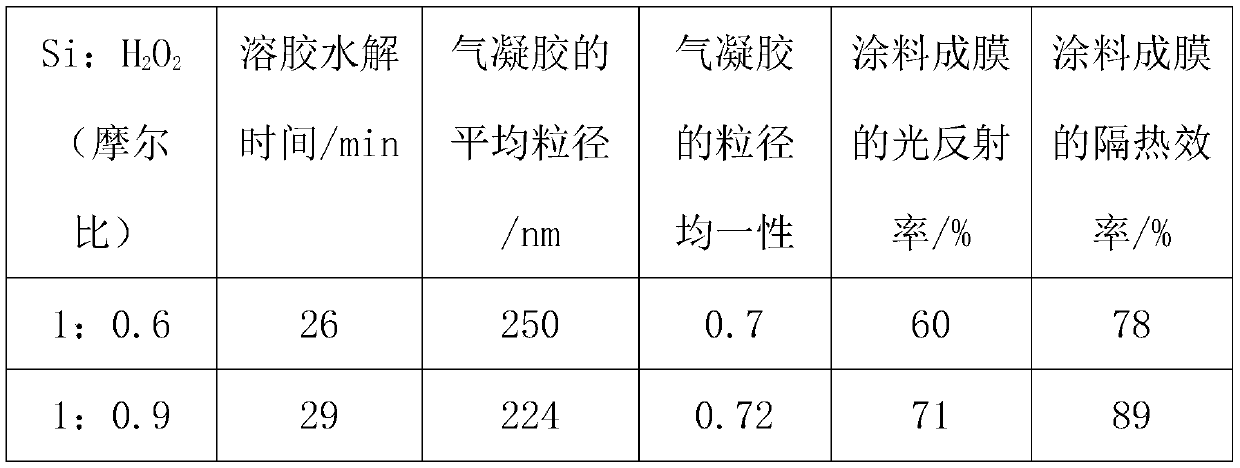

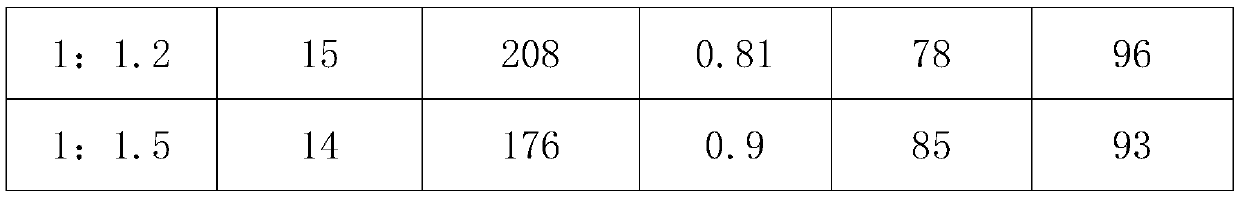

[0029] S1, according to the molar ratio of raw materials, in the mixed solution of 10 parts of ethanol and 2-10 parts of pure water, add 1 part of ethyl orthosilicate dropwise, add 2-5 parts of hydrogen peroxide solution, and then dropwise add 2-5 parts titanium tetrachloride, stirred for 10-30min to obtain solution A;

[0030] S2, set up a spray room, heat the ammonia water, pass the ammonia gas into the spray room, install an atomizing nozzle on the top of the spray room, spray solution A into the spray room through the atomizing nozzle, and obtain nano-coagulation Glue microsphere B;

[0031] S3, placing the nanogel microspheres B in a spray chamber for static aging, and the aging time is 10-20h;

[0032] S4, take out the aged nanogel microspheres B, and pass CO 2 Supercritical drying to obtain xerogel powder C;

[0033] S5, under the condition of high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com