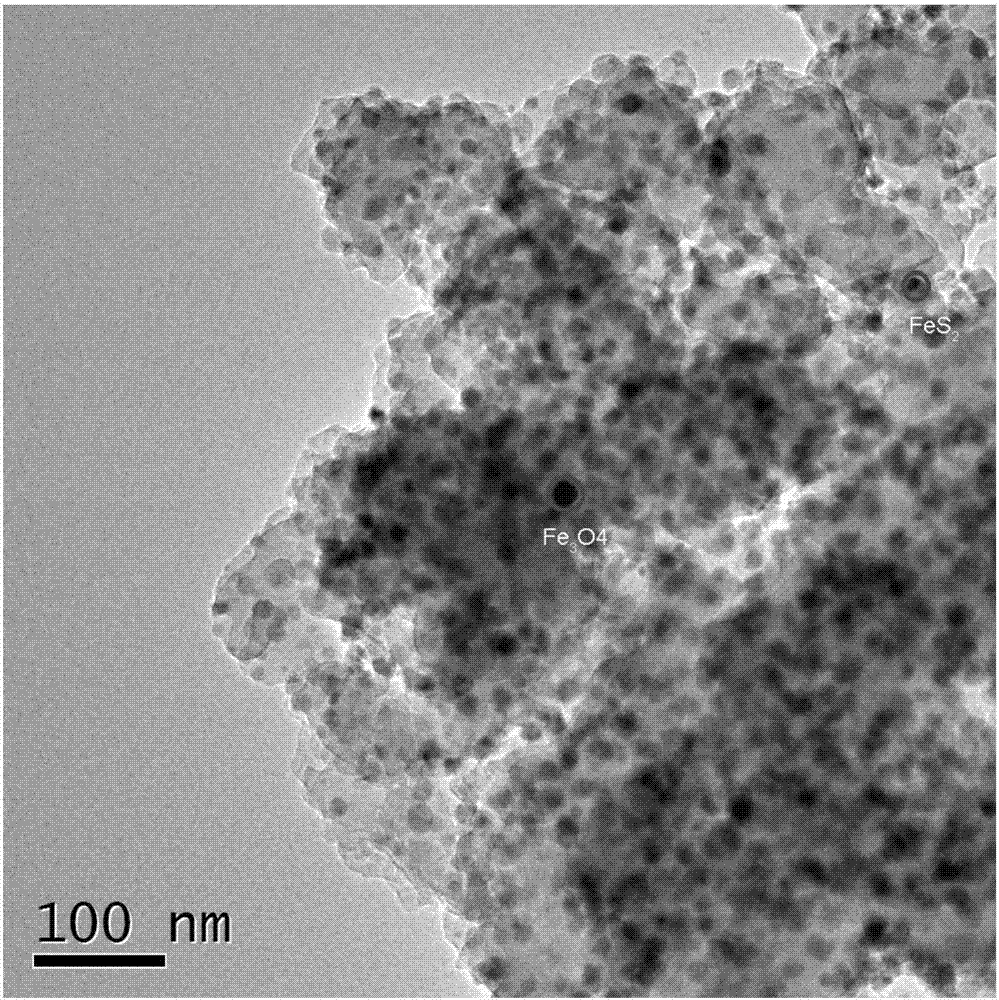

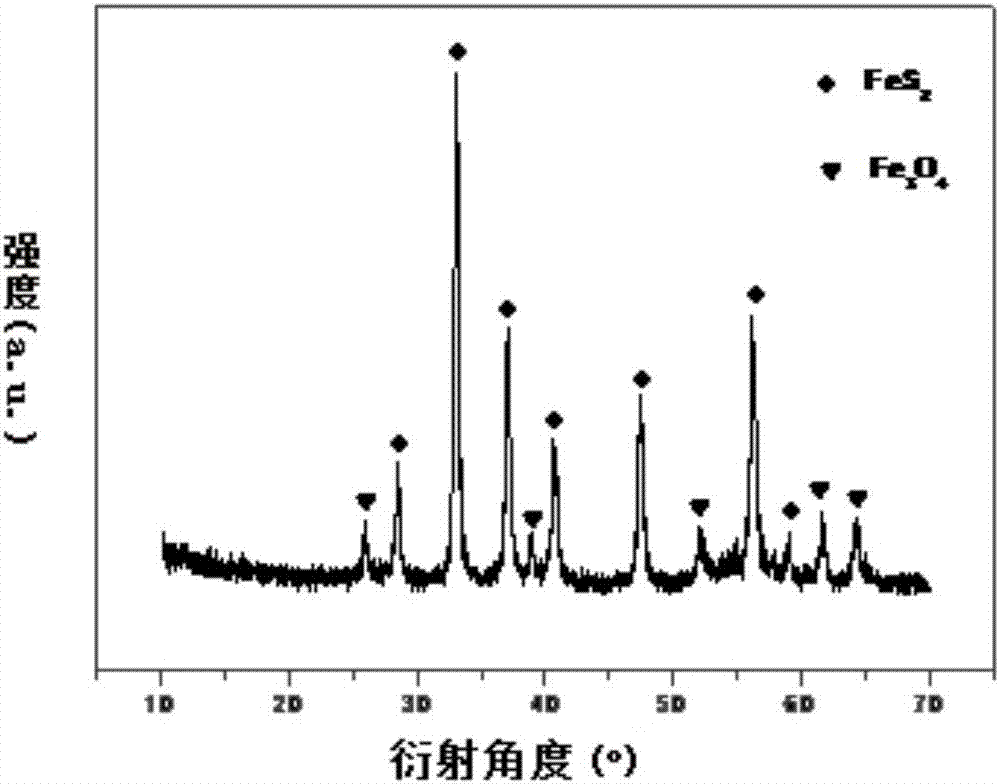

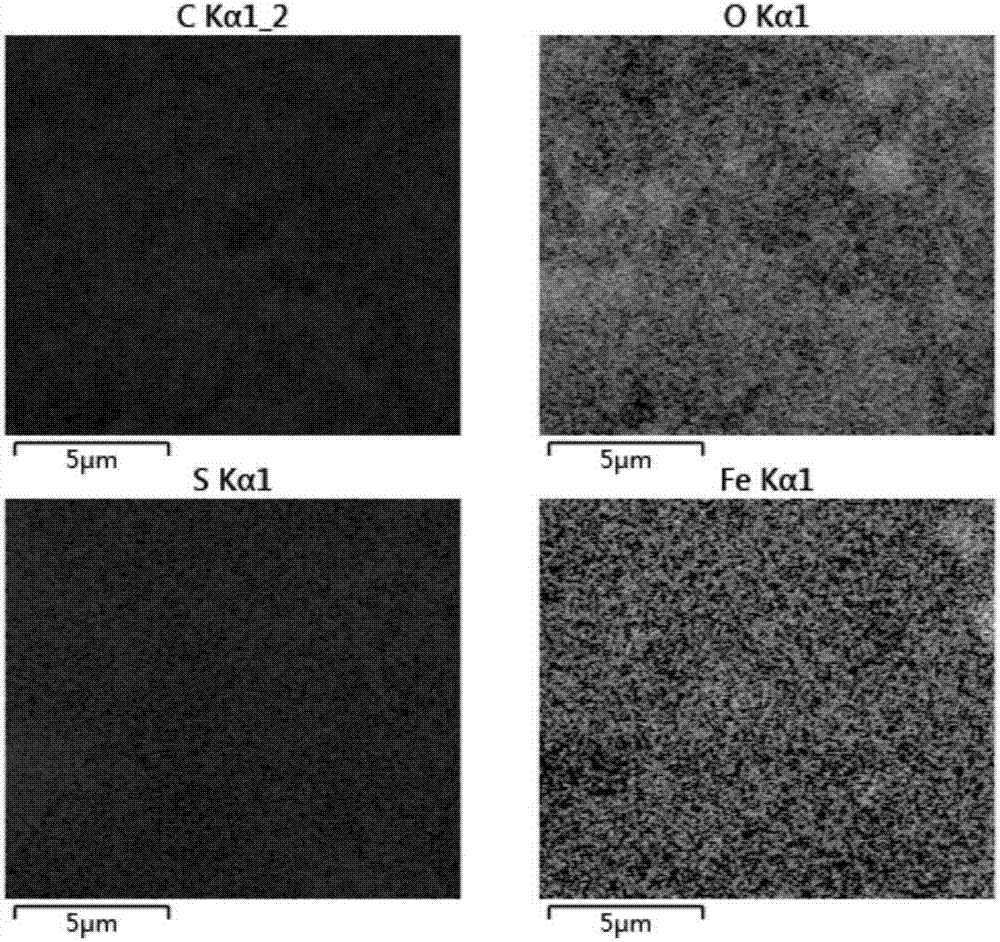

Sodium ion battery anode material FeS2/Fe3O4/C and preparation method of same

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low electrochemical performance and achieve good cycle performance, strong adaptability, and high Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of sodium ion battery FeS 2 / Fe 3 o 4 The preparation method of / C negative electrode material, concrete steps are as follows:

[0040] (1) prepare 0.1mol / L lignosodium solution and ferric nitrate solution respectively;

[0041] (2) Measure the solution prepared in step (1) according to the molar ratio of Fe:S of 1:2, slowly add 20ml of ferric nitrate solution into 40ml of lignosodium solution, mix and stir for 1h until pH=3, and obtain Solution A;

[0042] (3) Put the solution A into the reactor, heat it at 180°C for 24 hours, cool it down to room temperature naturally, take out the mixture, and centrifuge to obtain a brown-black precipitate;

[0043] (4) drying the precipitate in step (3) at 60° C. for 2 hours to obtain a black powder, which is fully ground to obtain a composite material precursor;

[0044] (5) The precursor obtained in step (4) was calcined at 500°C for 6h under the protection of nitrogen atmosphere, and cooled naturally to room temperatu...

Embodiment 2

[0051] A kind of sodium ion battery FeS 2 / Fe 3 o 4 The preparation method of / C negative electrode material, concrete steps are as follows:

[0052] (1) prepare 0.1mol / L lignosodium solution and ferric nitrate solution respectively;

[0053] (2) Measure the solution prepared in step (1) according to the molar ratio of Fe:S of 1:1, slowly add 30ml ferric nitrate solution to 30ml lignosodium solution, mix and stir for 1h until pH=2, and obtain Solution A;

[0054] (3) Put the solution A into the reactor, heat it at 160°C for 48 hours, cool it down to room temperature naturally, take out the mixture, and centrifuge to obtain a brown-black precipitate;

[0055] (4) drying the precipitate in step (3) at 60° C. for 2 hours to obtain a black powder, which is fully ground to obtain a composite material precursor;

[0056] (5) The precursor obtained in step (4) is calcined at 400°C for 8 hours under the protection of nitrogen atmosphere, and cooled naturally to room temperature t...

Embodiment 3

[0059] A kind of sodium ion battery FeS 2 / Fe 3 o 4 The preparation method of / C negative electrode material, concrete steps are as follows:

[0060] (1) prepare 0.1mol / L lignosodium solution and ferric nitrate solution respectively;

[0061] (2) Measure the solution prepared in step (1) according to the molar ratio of Fe:S of 1:3, slowly add 15ml of ferric nitrate solution into 45ml of lignosodium solution, mix and stir for 1h until pH=4, and obtain Solution A;

[0062] (3) Put the solution A into the reactor, heat it at 200°C for 12 hours, cool it down to room temperature naturally, take out the mixture, and centrifuge to obtain a brown-black precipitate;

[0063] (4) drying the precipitate in step (3) at 60° C. for 2 hours to obtain a black powder, which is fully ground to obtain a composite material precursor;

[0064] (5) The precursor obtained in step (4) is calcined at 600°C for 4 hours under the protection of nitrogen atmosphere, and cooled naturally to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com