Oxidation modification method of graphite negative electrode material, graphite negative electrode material and lithium ion battery

A graphite negative electrode and oxidation modification technology, which is applied in the direction of graphite, battery electrodes, secondary batteries, etc., can solve the problems of unsatisfactory improvement of graphite conductivity, cycle performance, difficult operation control, and poor process stability, etc., to achieve excellent electricity Chemical properties, ease of control, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

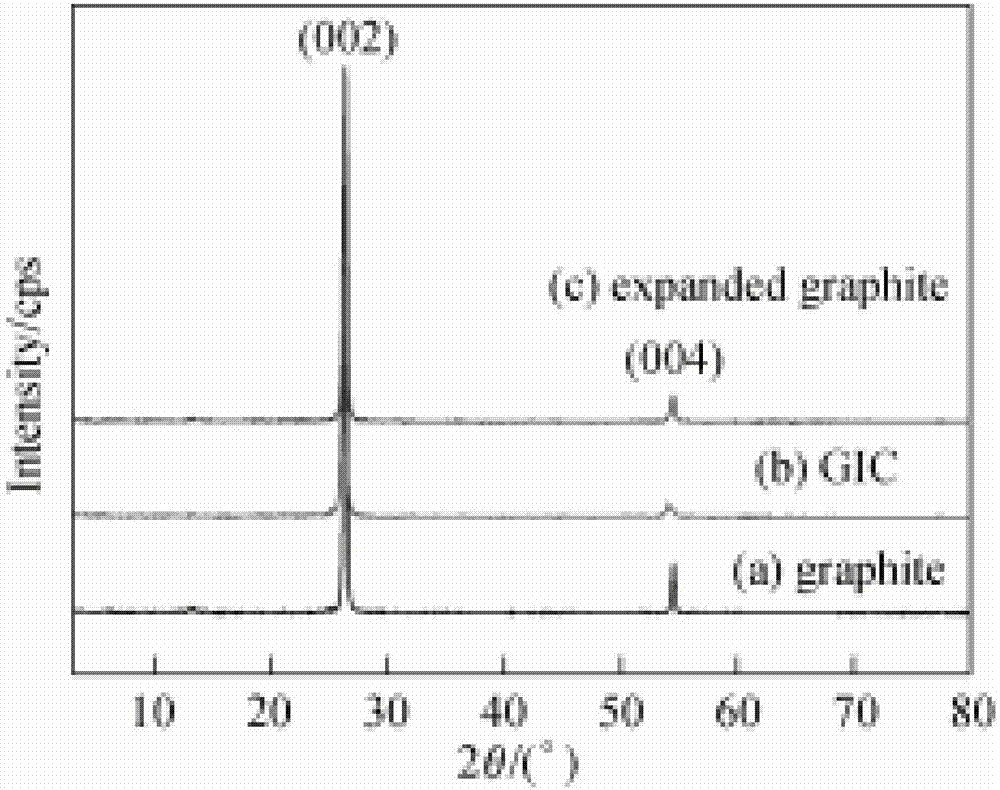

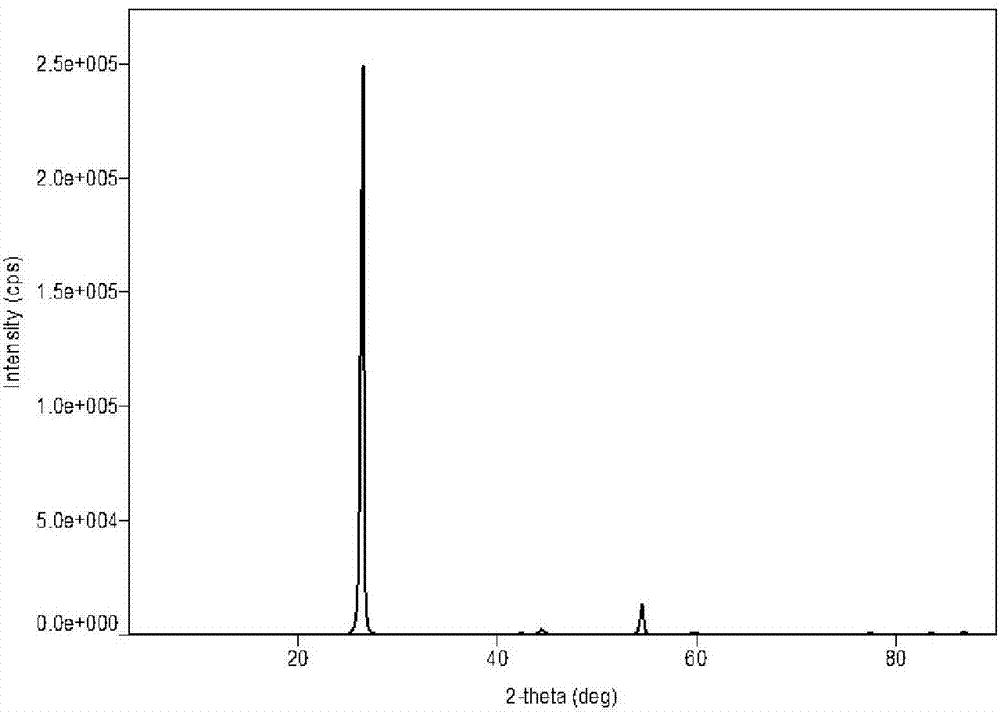

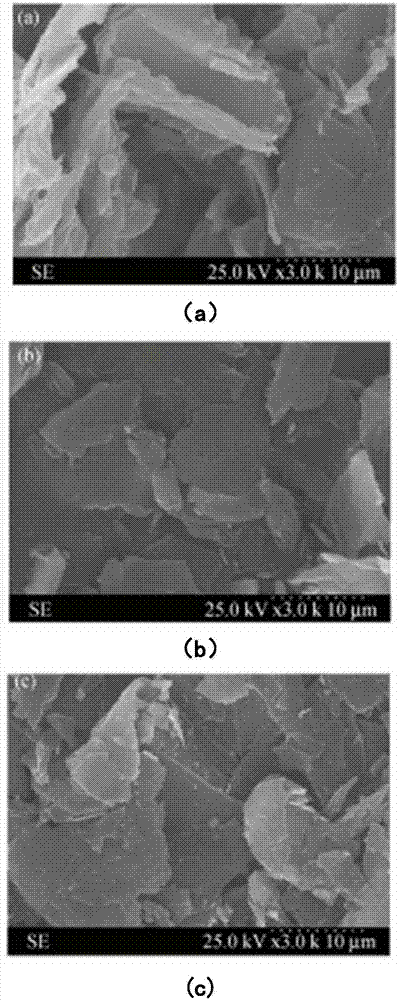

[0099] A method for oxidation modification of a graphite negative electrode material, comprising the following steps:

[0100] Weigh the natural graphite and liquid bromine according to the mass ratio of 1:4, put them in a sealed container, stir at a constant temperature of 30°C and a constant speed of 400r / min for 4 hours; wash with a 75% ethanol solution 3 times; filter the mixed solution after washing, add water continuously to neutralize during the filtration process, stop filtering until the pH value of the solution is 6.8; dry the filtered sample at 90°C to obtain the intermediate ;

[0101] The intermediate is calcined for 4 hours in an argon protective atmosphere at a temperature of 800° C.; ground to obtain a graphite negative electrode material.

Embodiment 2

[0103] A method for oxidation modification of a graphite negative electrode material, comprising the following steps:

[0104] Weigh the natural graphite and liquid bromine according to the mass ratio of 1:8, put them in a sealed container, stir at a constant temperature of 55°C and a constant speed of 500r / min for 5 hours; wash with 95% ethanol solution 3 times; filter the mixed solution after washing, add water continuously to neutralize during the filtration process, stop filtering until the pH value of the solution is 7; dry the filtered sample at 95°C to obtain the intermediate ;

[0105] The intermediate is calcined for 3 hours in a helium protective atmosphere at a temperature of 850° C.; ground to obtain a graphite negative electrode material.

Embodiment 3

[0107] A method for oxidation modification of a graphite negative electrode material, comprising the following steps:

[0108] (a) Mixing and stirring: Weigh the natural spherical graphite and liquid bromine according to the mass ratio of 1:6, and put them in a sealed tank, and put the sealed tank on a magnetic stirrer with a constant temperature of 40°C and a constant speed of 450r / Min stirred for 6 hours;

[0109] (b) washing: first use the redundant liquid bromine gas that the basic aluminum oxide adsorbent absorbs to volatilize, and then wash 4 times with the ethanol solution that concentration is 80%;

[0110] (c) Filtration: filter by suction filtration, add water continuously to neutralize the mixed solution after washing in the suction filtration process, until the pH value of the solution is 7, stop the suction filtration;

[0111] (d) drying: the filtered sample is dried in a blast drying oven at a drying temperature of 100° C. to obtain an intermediate;

[0112] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com