Green production method of L-aspartic acid

A technology of aspartic acid and ammonium aspartate, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high comprehensive cost, difficult separation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

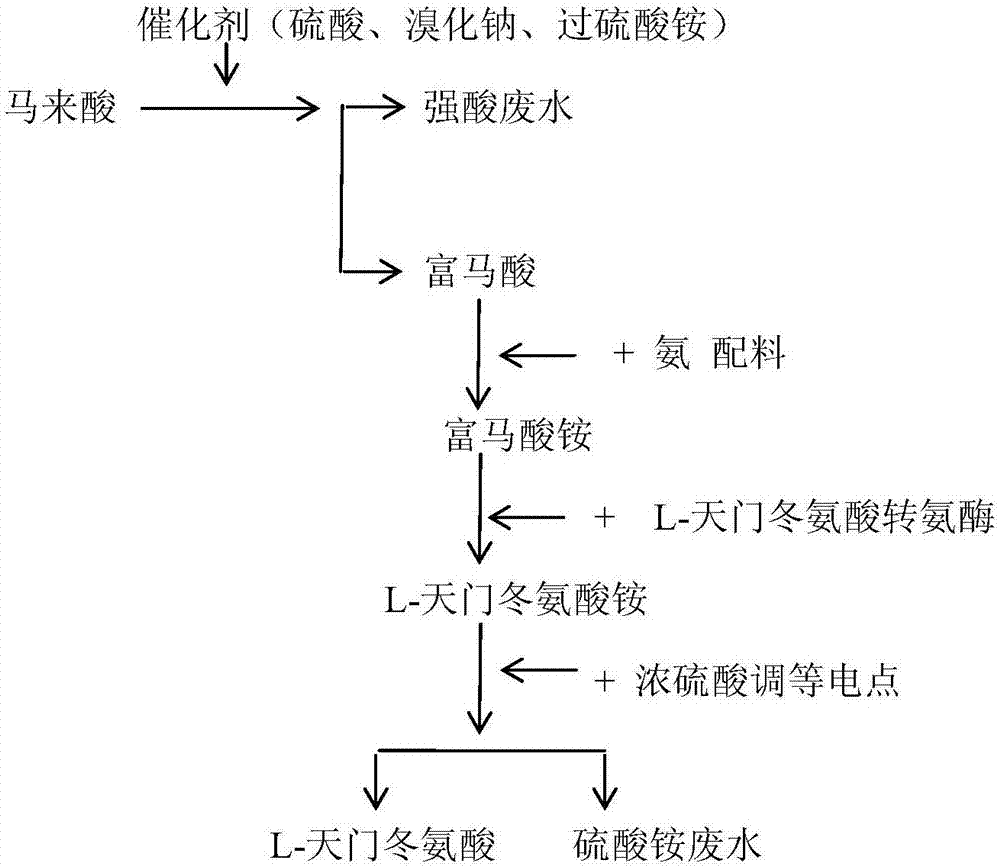

Problems solved by technology

Method used

Image

Examples

Embodiment 1

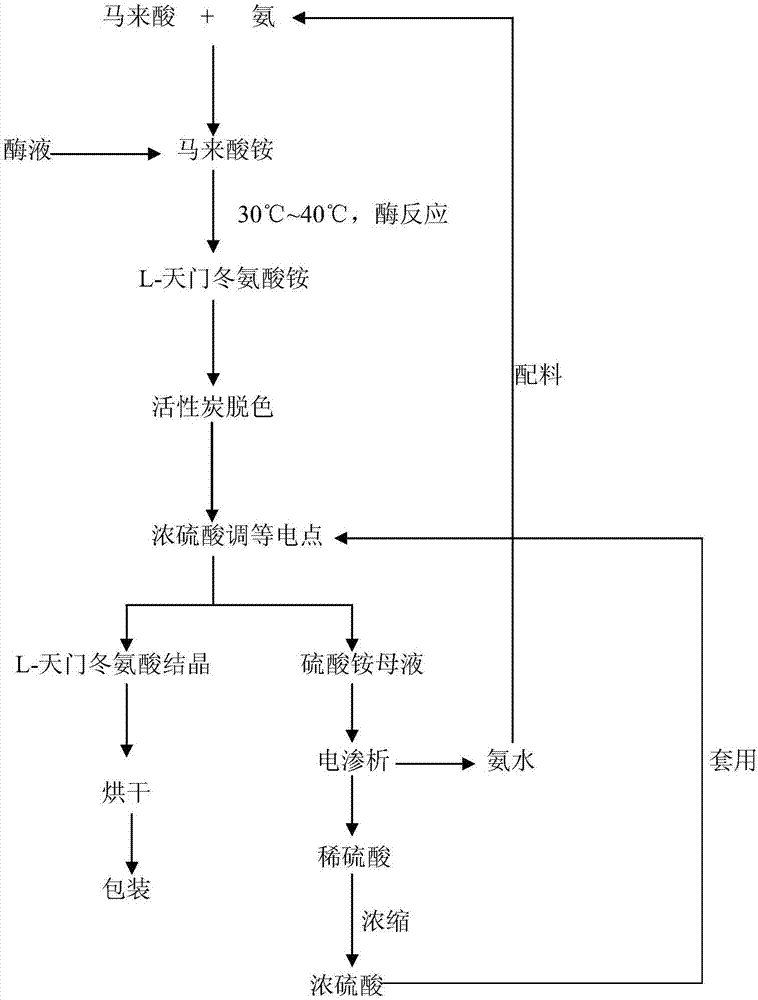

[0025] A method for preparing L-aspartic acid, such as figure 1 shown, including the following steps:

[0026] 1) maleic acid reacts with ammonia to obtain ammonium maleate;

[0027] 2) Enzyme isomerization

[0028] 2.1) The maleate isomerase and L-aspartate transaminase genes are transferred into microbial Escherichia coli for fermentation, and the fermentation broth contains 0.02% magnesium sulfate, 0.1% potassium dihydrogen phosphate, 0.2 % sodium chloride, 1.5% corn steep liquor, the pH of the culture solution is 6-7, the fermentation temperature is 35°C, the OD value is 0.2-0.3, and the culture time is 15 hours, the enzyme liquid containing two kinds of enzymes is obtained ;

[0029] 2.2) Stirring the ammonium maleate obtained in step 1) and the enzyme solution obtained in step 2.1) at 30° C. for an enzyme reaction to obtain an ammonium L-aspartate feed solution;

[0030] 3) Add 0.5% activated carbon to the L-aspartic acid ammonium feed solution obtained in step 2.2) ...

Embodiment 2

[0042] A method for preparing L-aspartic acid, such as figure 1 shown, including the following steps:

[0043] 1) maleic acid reacts with ammonia to obtain ammonium maleate;

[0044] 2) Enzyme isomerization

[0045] 2.1) Maleate isomerase and L-aspartate transaminase genes are transferred into microbial Escherichia coli for fermentation, and the fermentation broth contains 0.03% magnesium sulfate, 0.05% potassium dihydrogen phosphate, 0.3 % sodium chloride, 1.2% corn steep liquor, the pH of the culture solution is 6-7, the fermentation temperature is 36°C, the OD value is 0.3-0.4, and the culture time is 18 hours, the enzyme liquid containing two kinds of enzymes is obtained ;

[0046] 2.2) Stirring the ammonium maleate obtained in step 1) and the enzyme solution obtained in step 2.1) at 35° C. for an enzyme reaction to obtain an ammonium L-aspartate feed solution;

[0047] 3) Add 0.75% activated carbon to the ammonium L-aspartate feed solution obtained in step 2.2) to decol...

Embodiment 3

[0052] A method for preparing L-aspartic acid, such as figure 1 shown, including the following steps:

[0053] 1) maleic acid reacts with ammonia to obtain ammonium maleate;

[0054] 2) Enzyme isomerization

[0055] 2.1) Maleate isomerase and L-aspartate transaminase genes are transferred into microbial Escherichia coli for fermentation, and the fermentation broth contains 0.01% magnesium sulfate, 0.2% potassium dihydrogen phosphate, 0.4 % sodium chloride, 1.5% corn steep liquor, the pH of the culture solution is 6-7, the fermentation temperature is 37°C, the OD value is 0.2-0.3, and the culture time is 16 hours, the enzyme solution containing two enzymes is obtained ;

[0056] 2.2) Stirring the ammonium maleate obtained in step 1) and the enzyme solution obtained in step 2.1) at 38° C. for an enzyme reaction to obtain ammonium L-aspartate feed solution;

[0057] 3) Add 0.5% activated carbon to the ammonium L-aspartate feed solution obtained in step 2.2) for decolorization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com