Alumina-carbon drain hole brick toughened with homogenizing material and production method thereof

A production method and a technology of homogenizing materials, applied in the field of aluminum-carbon drain bricks, can solve the problems of cracks in drain bricks, affect the service life, increase material consumption, etc., increase high-temperature volume stability, and improve thermal shock resistance property, the effect of suppressing crack phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

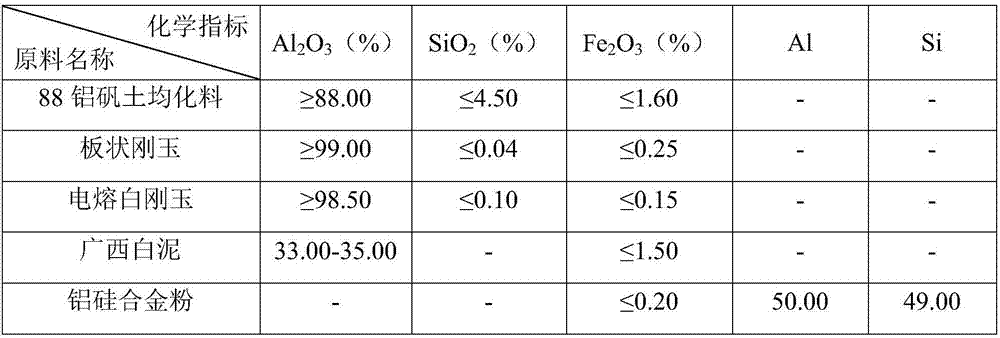

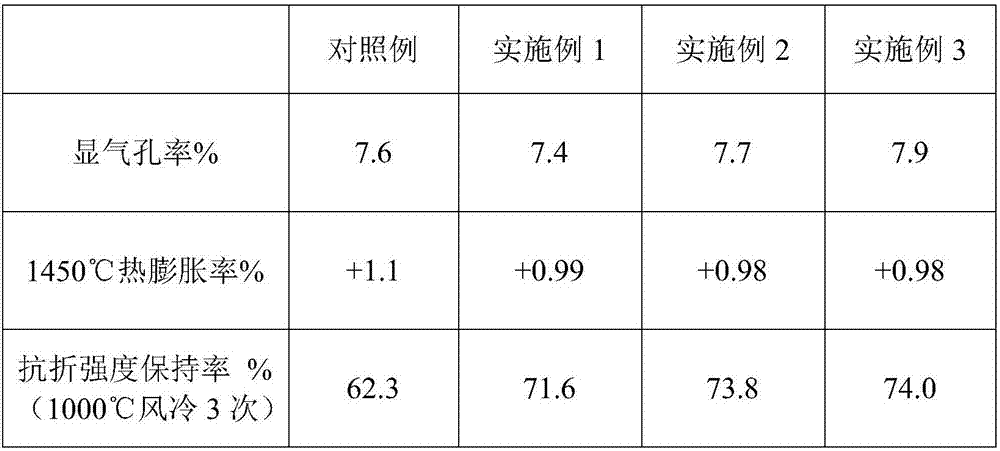

Embodiment 1

[0027] An aluminum carbon sewer brick toughened by a homogenized material, comprising the following raw materials in weight percentage: 20% of 88 bauxite homogenized material, 48% of tabular corundum, 8% of fused white corundum, 2% of -298 flake graphite, 7% aluminum-silicon alloy powder, 9% active a-alumina powder, 6% Guangxi white mud, the total amount of the above raw materials is 100%; plus 3.5% phenolic resin binder of the total weight of the above-mentioned raw materials.

[0028] The 88 bauxite homogenized material includes two particle sizes, 1mm≤particle size1<3mm and 3mm≤particle size2≤5mm, the weight ratio of the 88 bauxite homogenized material with particle size 1 and particle size 2 1:1; the plate-like alumina includes two particle sizes, 0mm<particle size1<1mm and 1mm≤particle size2≤3mm, the weight ratio of the plate-like alumina with particle size 1 and particle size 2 is 33: 15. The fused white corundum is 325 mesh fine powder, the -298 flake graphite is -200 m...

Embodiment 2

[0033] An aluminum carbon sewer brick toughened by homogenized material, comprising the following raw materials in weight percentage: 25% of 88 bauxite homogenized material, 45% of tabular corundum, 12% of fused white corundum, 1% of -298 flake graphite, 6% aluminum-silicon alloy powder, 6% active a-alumina powder, 5% Guangxi white mud, the total amount of the above raw materials is 100%; plus 3.5% of the total weight of the above raw materials phenolic resin binder.

[0034] The 88 bauxite homogenized material includes two particle sizes, 1mm≤particle size1<3mm and 3mm≤particle size2≤5mm, the weight ratio of the 88 bauxite homogenized material with particle size 1 and particle size 2 1.5:1; the plate-like alumina includes two particle sizes, 0mm<particle size1<1mm and 1mm≤particle size2≤3mm, the weight ratio of the plate-like alumina with particle size 1 and particle size 2 is 5: 2; the fused white corundum is 325 mesh fine powder, the -298 flake graphite is -200 mesh fine po...

Embodiment 3

[0037] An aluminum carbon sewer brick toughened by a homogenized material, comprising the following raw materials in weight percentage: 30% of 88 bauxite homogenized material, 38% of tabular corundum, 10% of fused white corundum, 2% of -298 flake graphite, 8% aluminum-silicon alloy powder, 8% active a-alumina powder, 4% Guangxi white mud, the total amount of the above raw materials is 100%; plus 3.5% phenolic resin binder of the total weight of the above-mentioned raw materials.

[0038] The 88 bauxite homogenized material includes two particle sizes, 1mm≤particle size1<3mm and 3mm≤particle size2≤5mm, the weight ratio of the 88 bauxite homogenized material with particle size 1 and particle size 2 2:1; the plate-like alumina includes two particle sizes, 0mm<particle size1<1mm and 1mm≤particle size2≤3mm, the weight ratio of the plate-like alumina with particle size 1 and particle size 2 is 33: 5; the fused white corundum is 325 mesh fine powder, the -298 flake graphite is -200 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com