Modified asphalt meeting PG 82-22 grade, and preparation method thereof

A technology for modifying asphalt and asphalt, applied in building components, building insulation materials, construction and other directions, can solve the problems of increasing the cost of modified asphalt, poor construction workability, high price, etc., and achieve good economic benefits, construction workability, etc. Good, improve the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

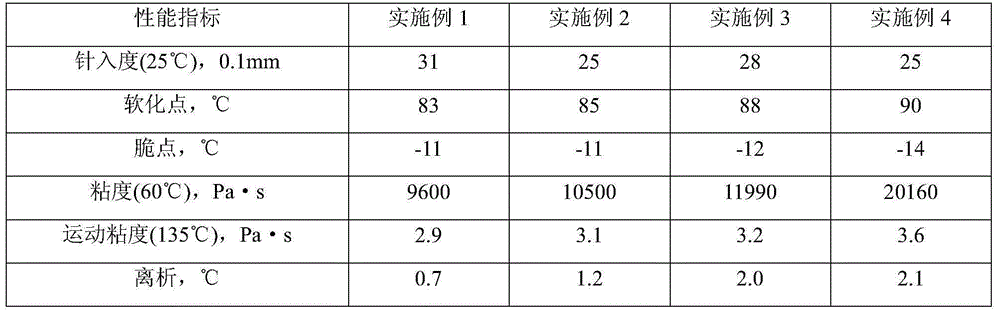

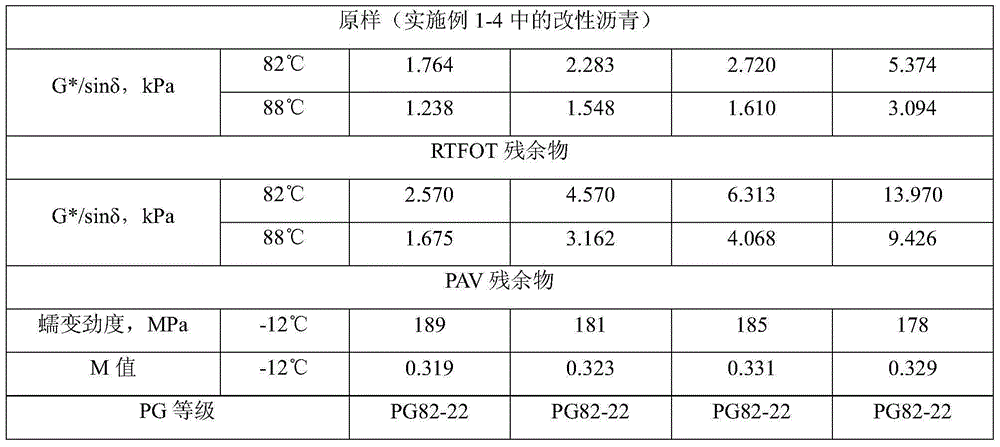

Embodiment 1

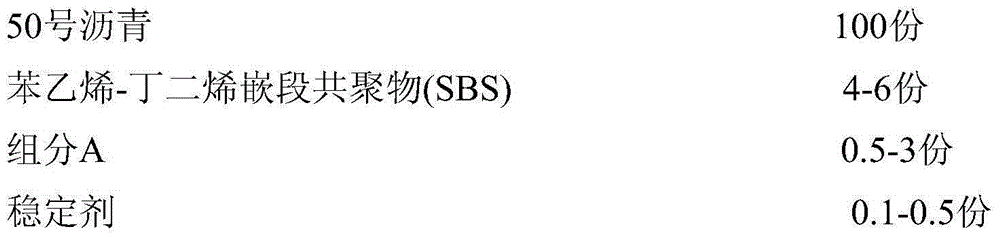

[0045] Embodiment 1, prepare the modified asphalt of PG82-22 grade:

[0046] The preparation method of the modified bitumen conforming to PG82-22 grade specifically comprises the following steps:

[0047] 1) Raw material preparation: Weigh 100 parts of No. 50 bitumen, 4 parts of SBS, 3 parts of PE and 0.35 parts of stabilizer according to the parts by mass, and set aside;

[0048]2) Preparation of modified asphalt: heat No. 50 asphalt to 185°C; then slowly add SBS and PE into No. HMD stabilizer, and stirred and developed at 180°C and 1000rpm for 5 hours, kept stirring and gradually lowered the temperature, and prepared modified asphalt conforming to PG82-22.

Embodiment 2

[0049] Embodiment 2, prepare the modified asphalt of PG82-22 grade:

[0050] The preparation method of the modified bitumen conforming to PG82-22 grade specifically comprises the following steps:

[0051] 1) Raw material preparation: Weigh 100 parts of No. 50 bitumen, 5 parts of SBS, 1 part of PE and 0.4 part of stabilizer according to the parts by mass, and set aside;

[0052] 2) Preparation of modified asphalt: heat No. 50 asphalt to 185°C; then slowly add SBS and PE into No. Industrial-grade sulfur powder, and stirred at 180°C and 2000rpm for 4 hours, kept stirring and gradually lowered the temperature to prepare modified asphalt that meets PG82-22.

Embodiment 3

[0053] Embodiment 3, prepare the modified asphalt of PG82-22 grade:

[0054] The preparation method of the modified bitumen conforming to PG82-22 grade specifically comprises the following steps:

[0055] 1) Raw material preparation: Weigh 100 parts of No. 50 bitumen, 4 parts of SBS, 1 part of polyphosphoric acid and 0.3 part of stabilizer according to the parts by mass, and set aside;

[0056] 2) Preparation of modified asphalt: heat No. 50 asphalt to 185°C; then slowly add SBS to No. anhydride, and stirred at 180°C and 2000rpm for 4 hours, and finally, added polyphosphoric acid at 170°C, and kept stirring at 170°C for 2 hours, kept stirring and gradually lowered the temperature, and prepared modified asphalt conforming to PG82-22.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com