Seamless expansion joint material adopting lime powder modified asphalt mortar of seamless expansion joint material and preparation method thereof

A modified asphalt, seamless expansion technology, applied in the field of road construction materials and engineering, can solve the problems of insufficient cohesiveness of the original pavement structure, increased overload, high temperature transition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

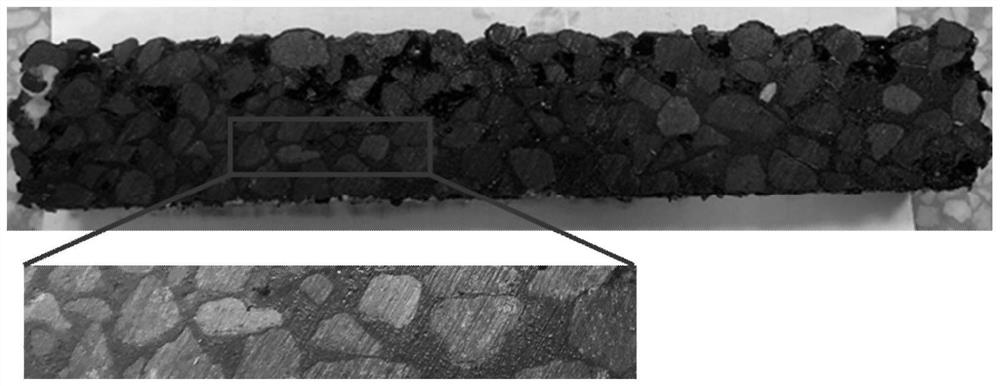

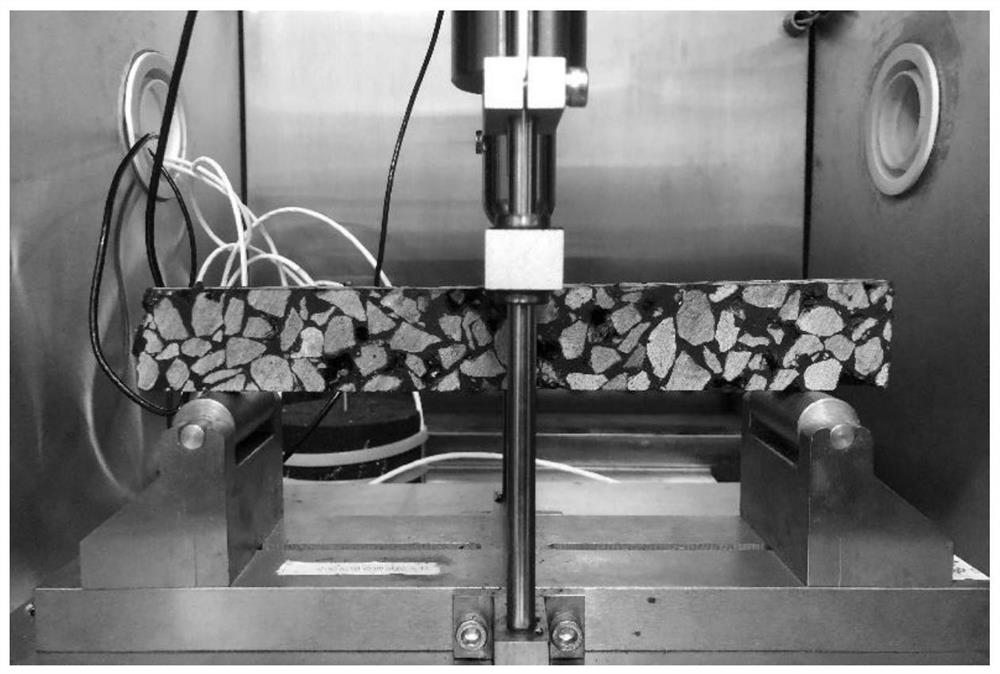

[0038] A seamless expansion joint material using lime powder modified asphalt mortar, which is made of the following raw materials in the following mass proportions: 622 parts of wide temperature range modified asphalt, 746 parts of lime powder, and 7200 parts of aggregate.

[0039] The PG classification of the wide temperature range modified asphalt is PG88-28, the penetration range at 25°C is 20-40, the softening point is not lower than 80°C, and the ductility at 25°C is not lower than 20cm.

[0040] Lime powder is calcareous lime powder, the content of CaO+MgO is not less than 90%, the content of MgO is not more than 5%, CO 2 The content is not more than 4%, SO 3 The content is not more than 2%, the particle size range is 800 mesh, and the 90μm sieve residue is not more than 7%.

[0041] The lithology of the aggregate is basalt, the particle size is 10-20mm, and the density is 2.5-3.0g / cm3 , The water absorption rate is 0.6-0.8%.

[0042] In this embodiment, the preparati...

Embodiment 2

[0055] A seamless expansion joint material using lime powder modified asphalt mortar, which is made of the following raw materials in the following mass proportions: 687 parts of wide temperature range modified asphalt, 825 parts of lime powder, and 7200 parts of aggregate.

[0056] The PG classification of wide temperature range modified asphalt is PG88-28, the penetration range at 25°C is 20-40, the softening point is not lower than 80°C, and the ductility at 25°C is not lower than 20cm.

[0057] Lime powder is calcareous lime powder, the content of CaO+MgO is not less than 90%, the content of MgO is not more than 5%, CO 2 The content is not more than 4%, SO 3 The content is not more than 2%, the particle size range is 800 mesh, and the 90μm sieve residue is not more than 7%.

[0058] The lithology of the aggregate is basalt, the particle size is 10-20mm, and the density is 2.5-3.0g / cm 3 , The water absorption rate is 0.6-0.8%.

[0059] In this embodiment, the preparation...

Embodiment 3

[0072] A seamless expansion joint material using lime powder modified asphalt mortar, which is made of the following raw materials in the following mass proportions: 753 parts of wide temperature range modified asphalt, 903 parts of lime powder, and 7200 parts of aggregate.

[0073] The PG classification of wide temperature range modified asphalt is PG88-28, the penetration range at 25°C is 20-40, the softening point is not lower than 80°C, and the ductility at 25°C is not lower than 20cm.

[0074] Lime powder is calcareous lime powder, the content of CaO+MgO is not less than 90%, the content of MgO is not more than 5%, CO 2 The content is not more than 4%, SO 3 The content is not more than 2%, the particle size range is 800 mesh, and the 90μm sieve residue is not more than 7%.

[0075] The lithology of the aggregate is basalt, the particle size is 10-20mm, and the density is 2.5-3.0g / cm 3 , The water absorption rate is 0.6-0.8%.

[0076] In this embodiment, the preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com