Nanomaterial modified rubber asphalt mixture and preparation method thereof

A technology of asphalt mixture and nano-materials, which is applied in the field of road engineering, can solve the problems of poor anti-rutting performance, increase the construction difficulty of rubber asphalt mixture, and high viscosity of rubber asphalt, and achieve good high-temperature anti-rutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

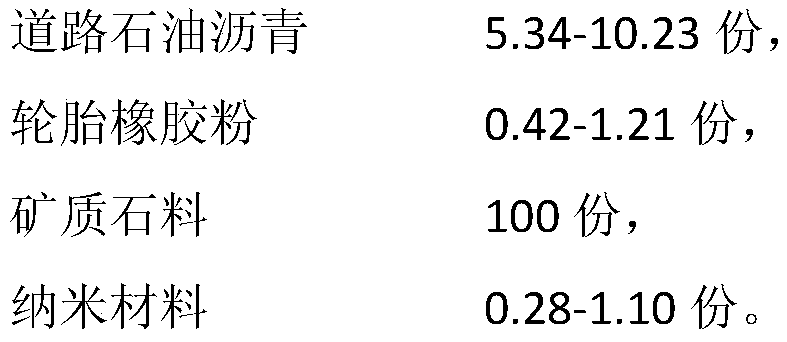

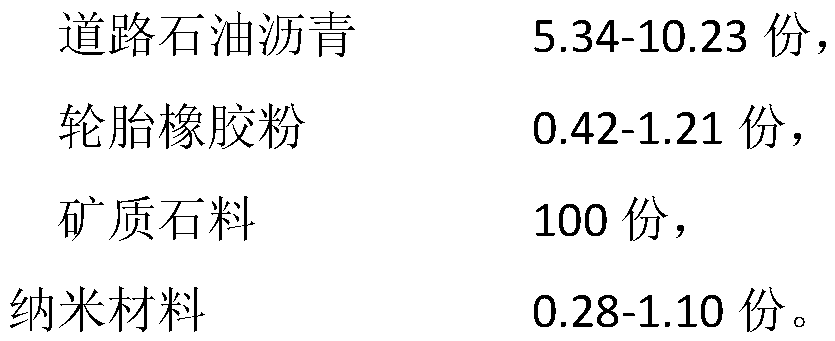

[0048]

[0049] A kind of preparation method of above-mentioned nano material modified rubber asphalt mixture, it comprises the steps:

[0050] (1) Add 0.42-1.21 parts of tire rubber powder to 5.34-10.23 parts of road petroleum asphalt, and stir at the first temperature to obtain rubber asphalt;

[0051] (2), adding 0.28-1.10 parts of nanomaterials to the above-mentioned rubber asphalt, stirring, shearing, and then stirring at a second temperature to obtain nano-modified rubber asphalt;

[0052] (3) Heat 100 parts of mineral stone to the third temperature, then add 7-11 parts of the above-mentioned nano-modified rubber asphalt, and stir to obtain a nano-material modified rubber asphalt mixture.

[0053] In fact, modified rubber asphalt is component A, and its total mass is 100 parts, wherein, the quality of tire rubber powder is 7-11 parts, and the quality of petroleum asphalt is 89-93 parts; mineral stone is component B, its The total mass is 100 parts, and component A acc...

Embodiment 1

[0062] The preparation method of the nano-calcium carbonate modified rubber asphalt mixture of the present embodiment comprises the steps:

[0063] (1), 0.56 parts of tire rubber powder are added to 7.44 parts of road petroleum asphalt, and at a first temperature of 180° C., stirred for 40 minutes to obtain rubber asphalt, wherein the tire rubber powder actually accounts for 7% by mass of the rubber asphalt, Road petroleum asphalt actually accounts for 93% of the mass percentage of rubber asphalt;

[0064] (2), add 0.32 parts of nano-calcium carbonate to the above-mentioned rubber asphalt (nano-calcium carbonate actually accounts for 4% by mass of the rubber asphalt), at the second temperature of 180°C, stir for 20min, then shear, shear The speed is 1500r / min, the shearing time is 40min, and the ordinary mixer is used to stir for 60min to obtain nano-modified rubber asphalt;

[0065] (3) Heat 100 parts of mineral stones to a third temperature of 200° C., then add 8 parts of t...

Embodiment 2

[0078] The preparation method of the nano zinc oxide modified rubber asphalt mixture of the present embodiment comprises the following steps:

[0079] (1), 0.80 parts of tire rubber powder are added to 9.00 parts of road petroleum asphalt, and at a first temperature of 180° C., stirred for 40 minutes to obtain rubber asphalt, wherein the tire rubber powder actually accounts for 8% by mass of the rubber asphalt, Road petroleum asphalt actually accounts for 90% of the mass percentage of rubber asphalt;

[0080] (2), add 0.80 parts of nano-zinc oxide to the above-mentioned rubber asphalt (nano-zinc oxide actually accounts for 8% by mass of rubber asphalt), at the second temperature of 180°C, stir for 20min, then shear, shear The speed is 2000r / min, the shearing time is 40min, and the ordinary mixer is used to stir for 60min to obtain nano-modified rubber asphalt;

[0081] (3) Heat 100 parts of mineral stones to a third temperature of 200° C., then add 10 parts of the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com