Measurement and control type cooling equipment for screw extruder

A technology of screw extruder and cooling equipment, applied in the field of screw extruder measurement and control cooling equipment, can solve the problems of waste of resources, low cooling efficiency, difficulty in controlling cooling speed, etc., and achieve strong adaptability, stability and reliable quality , the effect of real-time adjustment of accurate measurement and cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

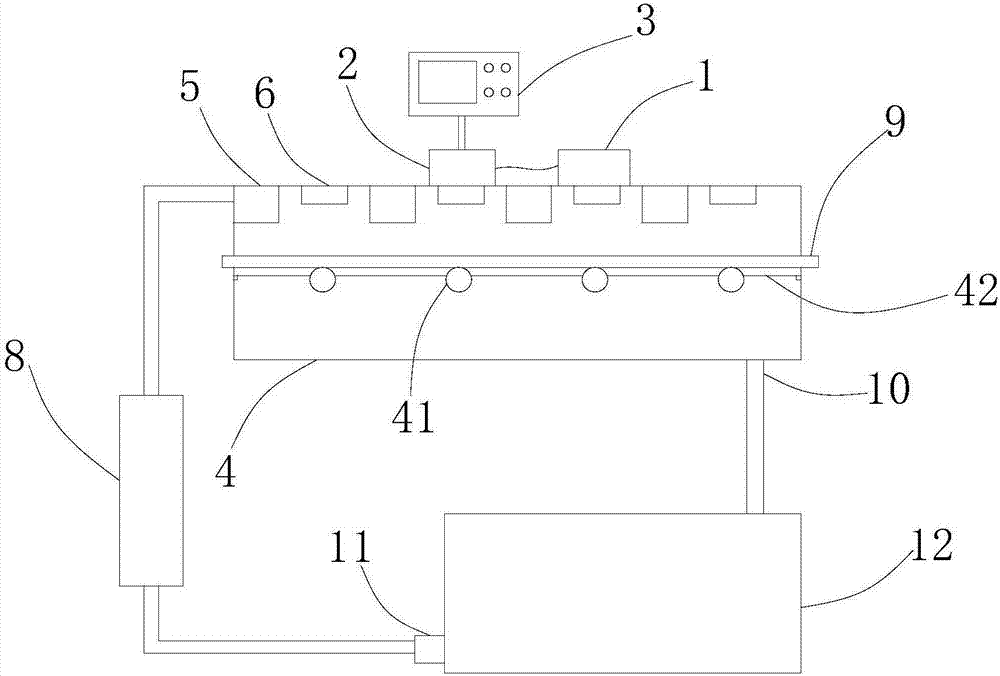

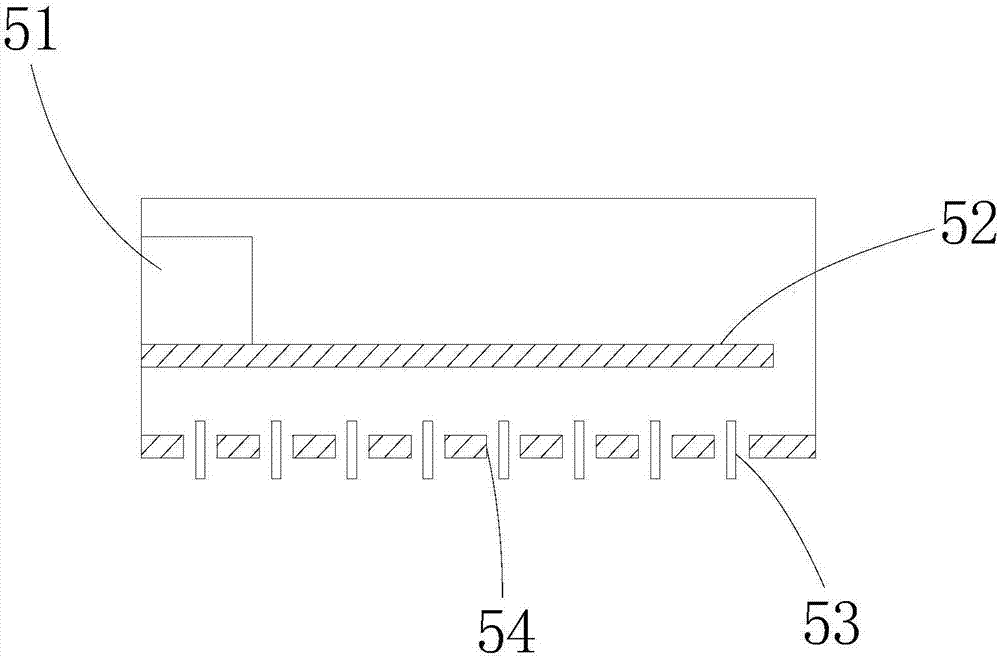

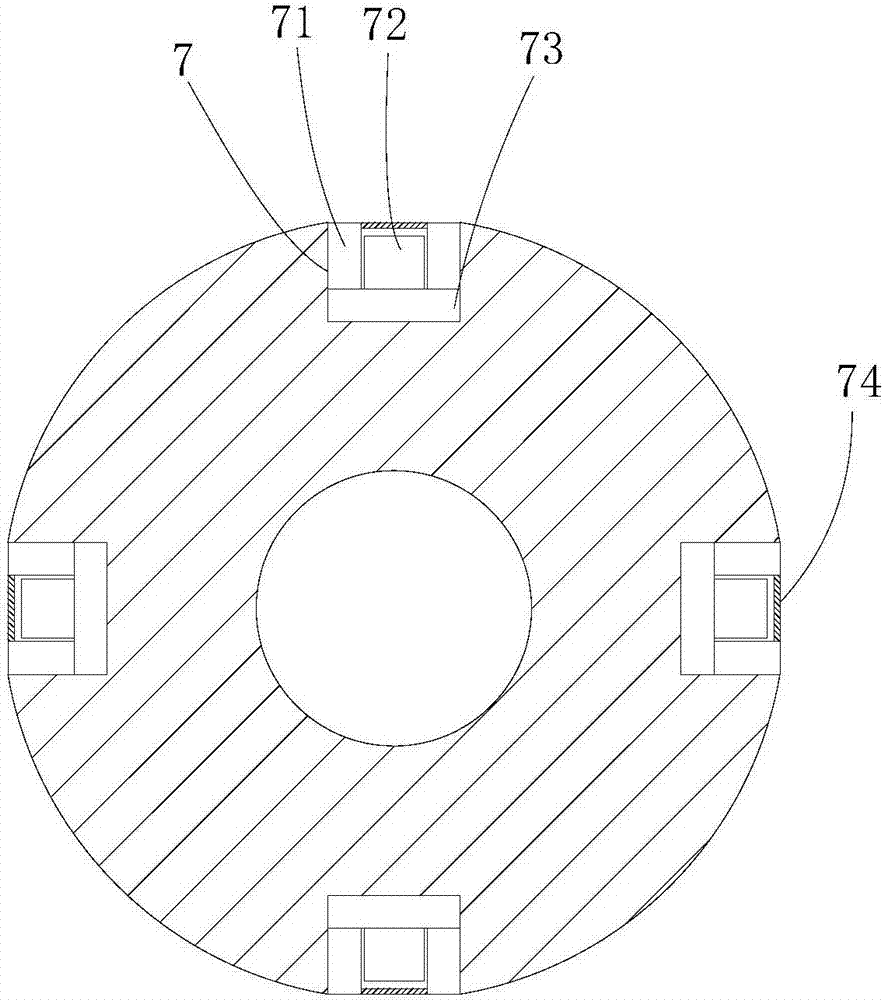

[0026] see Figure 1 to Figure 4 According to the embodiment of the screw extruder measurement and control cooling equipment provided by the present invention, the cooling equipment includes three cooling methods: water cooling, air cooling, and water cooling and air cooling, and the cooling equipment consists of a detection device 7, a cooling device, The controller 2, the controllable display device 3 and the tank structure 4 are composed, the cooling device includes the water shower device 5, the air supply device 6 and the refrigeration device 1, and the controller 2 is electrically connected with the controllable display device 3 , the lower part of the tank structure 4 is provided with a water tank 12 . The present invention accurately detects the temperature change during the plastic cooling process through the detection device 7, and controls the refrigeration device 1 through the controller 2 and the controllable display device 3 to adjust the cooling rate, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com