Anti-corrosion preprocessing method of engineering machinery oil tank

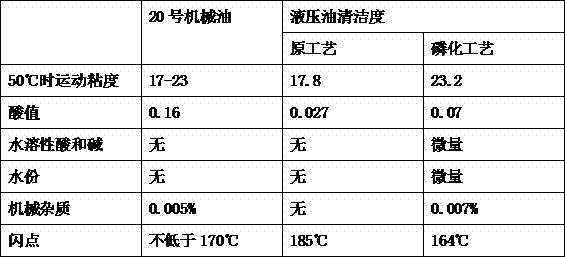

A kind of construction machinery and pretreatment technology, applied in the direction of metal material coating process, etc., can solve the problems of affecting the cleanliness of hydraulic oil, unstable protection quality, and damage of hydraulic system, and achieve enhanced corrosion resistance, stable quality, and cleanliness Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An anti-corrosion pretreatment method for an engineering machinery oil tank, comprising the following steps:

[0017] (1) Put the finished product of the formed oil tank into a degreasing agent solution with a concentration of 3%, heat it to 35°C and soak it in the bath for 30 minutes, then take it out and rinse it with clean water;

[0018] (2) Then soak the degreased primary product of the oil tank in a descaling solution with a temperature of 60°C and a weight ratio of 1:7 for 40 minutes, then take it out and dry it;

[0019] (3) Put the finished product of the oil tank after drying into the phosphating pool with a temperature of 94°C for treatment; the phosphating solution in the phosphating pool is made according to the following dosage ratio: ferrous dihydrogen phosphate 13g / L, dihydrogen phosphate Manganese hydrogen 15g / L, manganese nitrate 15g / L, nickel nitrate 1g / L, the balance is water;

[0020] (4) Carry out passivation treatment at 70°C for 15 minutes, and ...

Embodiment 2

[0024] An anti-corrosion pretreatment method for an engineering machinery oil tank, comprising the following steps:

[0025] (1) Put the formed fuel tank primary product into a degreasing agent solution with a concentration of 5%, heat it to 40°C and soak it for 40 minutes, then take it out and rinse it with clean water;

[0026] (2) Then soak the degreased primary product of the fuel tank in a descaling solution with a temperature of 65°C and a weight ratio of 1:7 for 50 minutes, then take it out and dry it;

[0027] (3) Put the first finished product of the oil tank after drying into the phosphating tank with a temperature of 98°C for treatment; the phosphating solution in the phosphating tank is made according to the following dosage ratio: ferrous dihydrogen phosphate 18g / L, dihydrogen phosphate Manganese hydrogen 20g / L, manganese nitrate 18g / L, nickel nitrate 3g / L, the balance is water;

[0028] (4) Carry out passivation treatment at 85°C for 15 minutes, and passivation ...

Embodiment 3

[0032] An anti-corrosion pretreatment method for an engineering machinery oil tank, comprising the following steps:

[0033] (1) Put the formed fuel tank primary product into a degreasing agent solution with a concentration of 4%, heat it to 38°C and soak it for 35 minutes, then take it out and rinse it with clean water;

[0034] (2) Put the degreased primary product of the oil tank into the descaling solution with a temperature of 63°C and a weight ratio of 1:7 for 45 minutes, then take it out and dry it;

[0035] (3) Put the finished product of the oil tank after drying into the phosphating pool with a temperature of 96°C for treatment; the phosphating solution in the phosphating pool is made according to the following dosage ratio: ferrous dihydrogen phosphate 15g / L, dihydrogen phosphate Manganese hydrogen 18g / L, manganese nitrate 17g / L, nickel nitrate 2g / L, the balance is water;

[0036] (4) Carry out passivation treatment at 80°C for 15 minutes, and passivation solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com