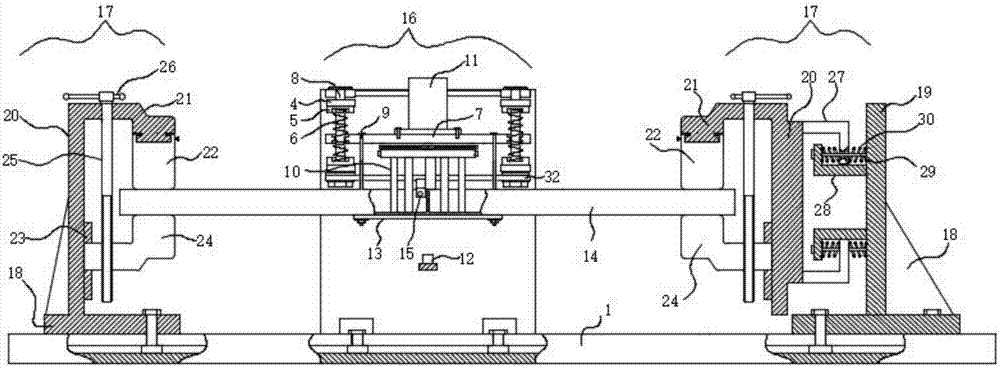

Simply supported type vibrating aging platform for beam component

A technology of vibration aging and beam components, which is applied in the field of material testing equipment, can solve the problems of reducing aging effect, increasing scrap rate, workpiece deformation, etc., and achieves the effects of improving life, eliminating residual stress, and adjusting amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

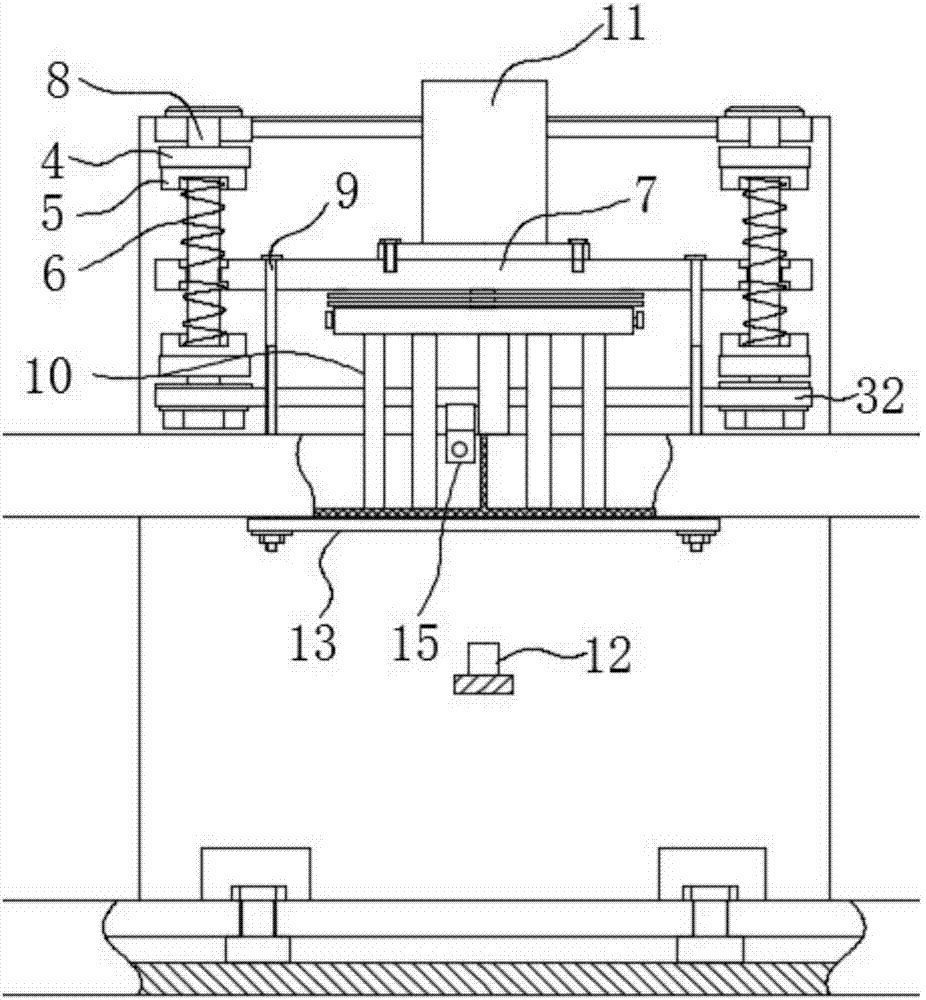

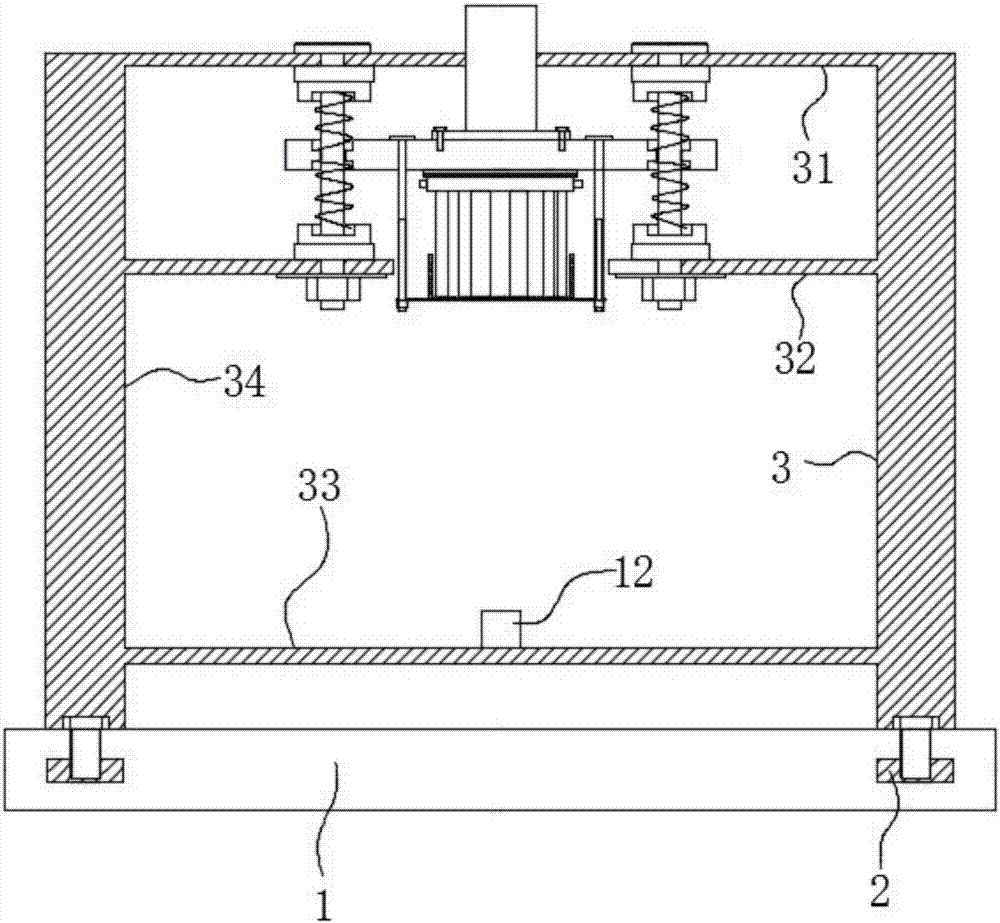

[0051] Laser displacement sensor 12 adopts FT50 RLA-20 laser displacement sensor; acceleration sensor 15 adopts DH131 piezoelectric acceleration sensor.

[0052] Under normal experimental conditions, the laser displacement sensor 12 is fixed on the lower bracket of the clamping part of the excitation source, and the acceleration sensor 24 is fixed on a component close to the clamping part of the center of the vibration source by bolts. Each sensor measures in real time and transmits the data to the dynamic data acquisition system, and then the system is connected to the PC terminal through the network cable, and the vibration acceleration and vibration displacement can be tested and analyzed in the computer operating system. It can also complete the test and analysis of stress and strain by pasting metal strain gauges on the workpiece, and finally complete the real-time storage, real-time display and real-time analysis of the four elements of vibration. The specific data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com