Oil-proof PE preservative film

A fresh-keeping film and anti-oil technology, which is applied to the types of packaging items, special packaging items, applications, etc., can solve the problems of increasing molecular density and not being able to effectively separate food from each other, so as to increase molecular density, prevent oil molecule penetration, and keep fresh good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

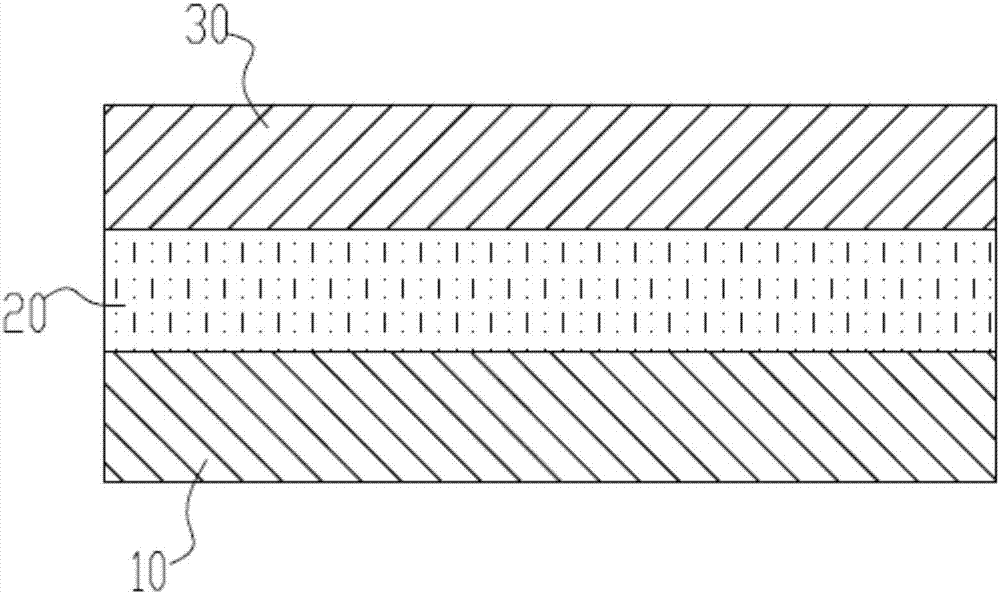

[0039] Such as figure 1 As shown, an oil-proof PE cling film includes an inner layer 10, a middle layer 20 and an outer layer 30 stacked in sequence; the thickness ratio of the inner layer 10, the middle layer 20 and the outer layer 30 is 1:1:1 , can also be 0.6:1.4:0.6 or 1.4:0.6:1.4.

[0040] The raw materials of the inner layer 10 include low-density polyethylene, high-density polyethylene, linear low-density polyethylene, polypropylene and metallocene linear low-density polyethylene with a weight ratio of 5:2:1:1:1, wherein the inner layer The weight ratio of low density polyethylene, high density polyethylene, linear low density polyethylene, polypropylene and metallocene linear low density polyethylene in layer 10 can also be 4.6:1.7:0.8:0.8:0.8 or 5.4:2.3 :1.2:1.2:1.2.

[0041] The raw materials of the middle layer 20 include low-density polyethylene, medium-density polyethylene, high-density polyethylene, polypropylene and metallocene linear low-density polyethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com