Heater heating element manufacturing method

A technology of heating element and manufacturing method, which is applied to electrical elements, ohmic resistance heating, electric heating devices, etc., to achieve the effects of compact structure, improved thermal conductivity, and convenient power control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

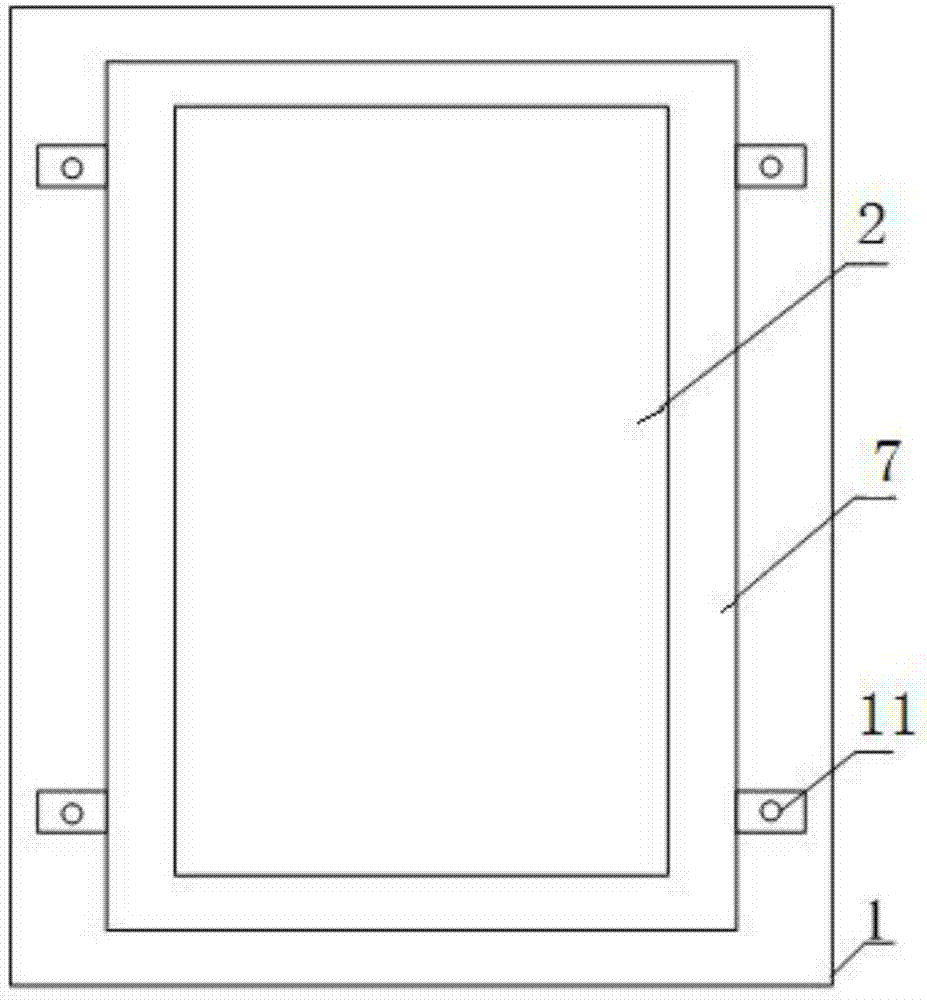

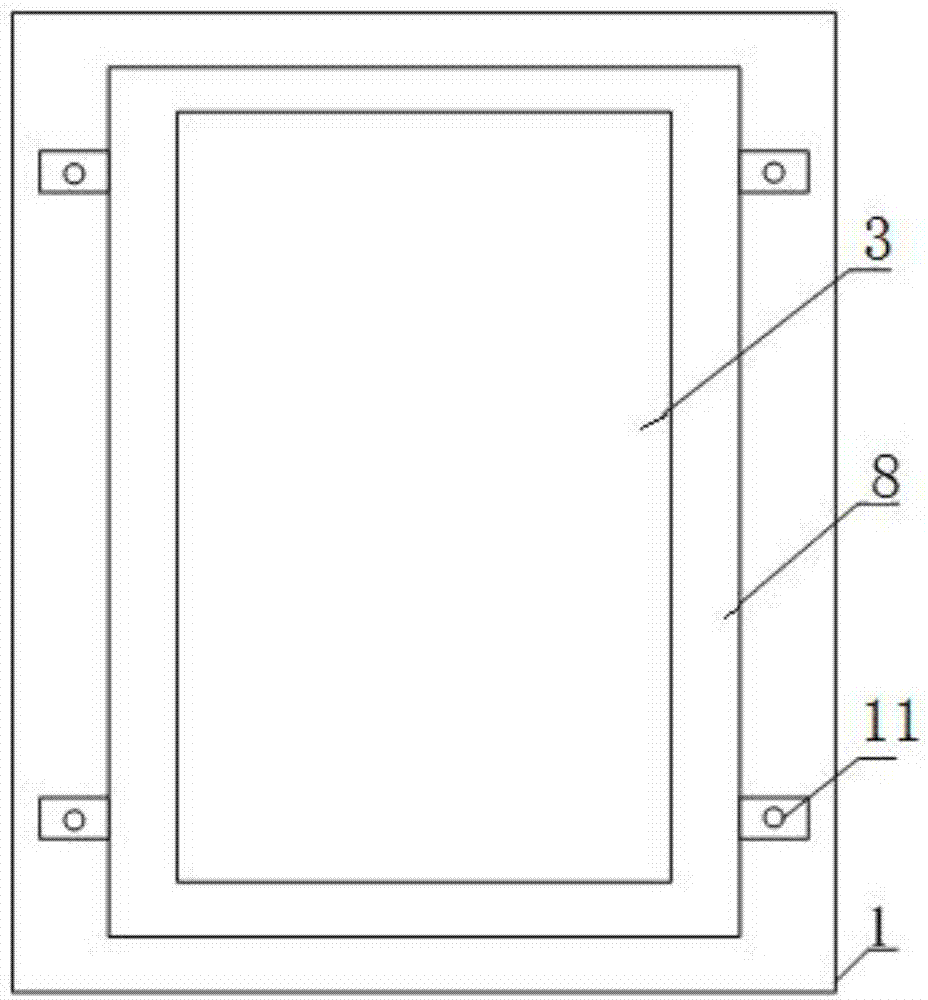

Image

Examples

Embodiment 1

[0034] Embodiment 1, during the plasma spraying process, the nozzle and the electrode of the spray gun are respectively connected to the positive and negative poles of the power supply. Working gas (such as helium, nitrogen, etc.) is passed between the nozzle and the electrode, and the arc is ignited by high-frequency sparks. The arc heats the gas and ionizes it to generate high-temperature plasma gas. The powder feeding gas pipe sends the pre-sprayed powder material into the high-temperature plasma gas and is quickly heated to a molten state. The plasma flame flow is formed with nitrogen or argon as the carrier gas. Spray at a certain speed to the surface of the preheated substrate to form a dense coating. When spraying metal or metal alloy, a certain amount of hydrogen can be mixed in the carrier gas as a reducing gas to prevent the coating from being oxidized during the formation process.

Embodiment 2

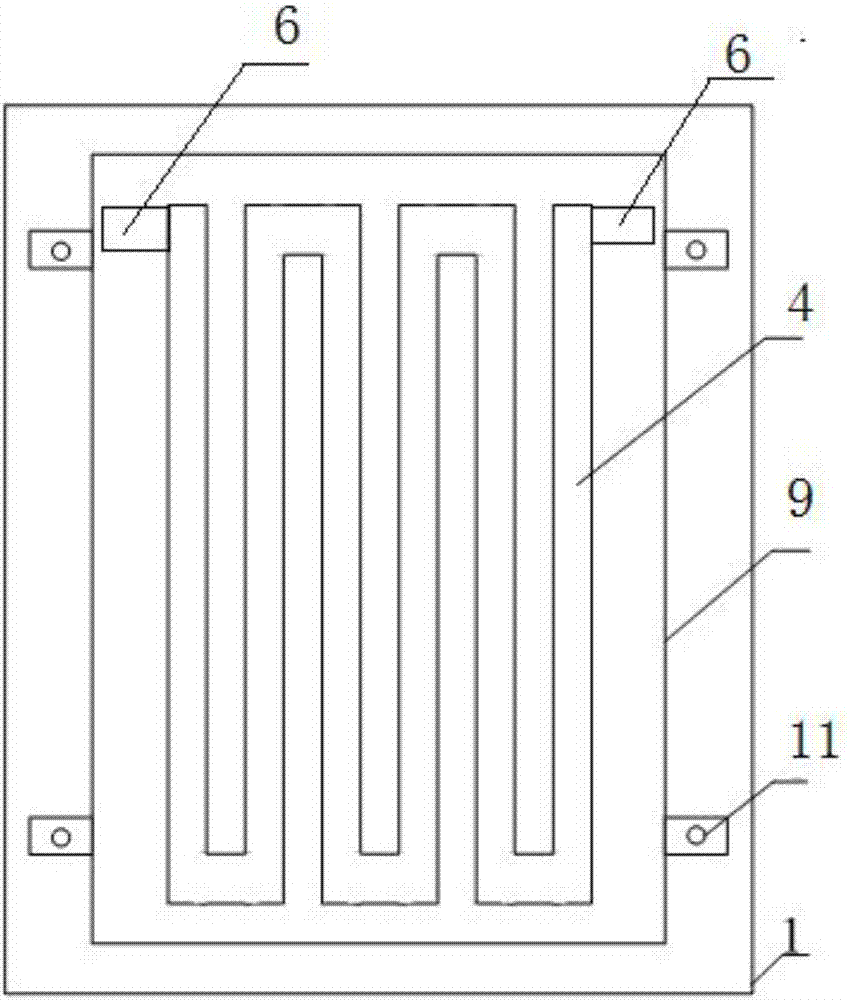

[0035] Embodiment 2, the heating layer 4 is sprayed on the first ceramic insulating layer 3 by a flame spraying method, and the flame spraying method includes the following steps:

[0036] The nickel-chromium alloy powder particles are injected into the flame through the powder feeding tube, and the flame heats the nickel-chromium alloy powder particles to a molten and semi-molten state;

[0037] Argon or nitrogen is used as the protective gas, and the nickel-chromium alloy powder particles are atomized by the protective gas flow, and sprayed onto the first ceramic insulating layer 3 at a speed of 2000m / s to form a dense heating layer 4 . Since the temperature of the molten and semi-molten state of nickel-chromium material has begun to drop before spraying reaches the alumina ceramic insulation layer, the temperature will drop in a large range when it reaches the spraying area of the heater, so that the temperature of the heating area is low and the residual stress is small. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com