Heavy metal ion adsorption film and preparation method thereof

A technology of heavy metal ions and adsorption membranes, which is applied in the fields of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., and can solve problems such as different treatment methods and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

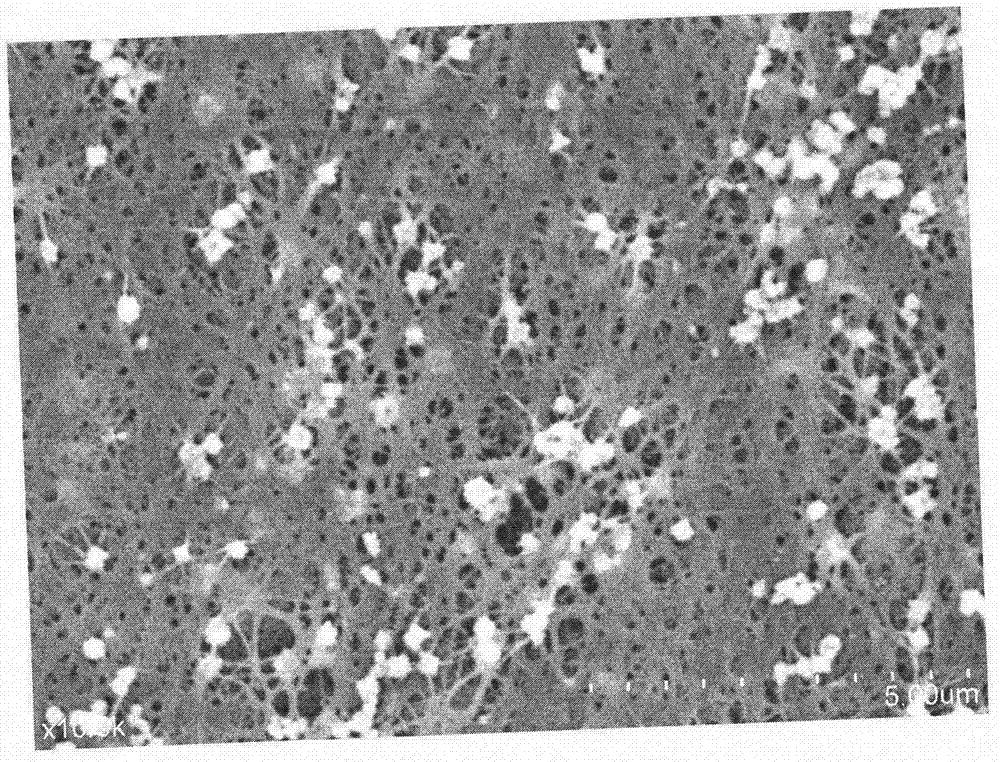

Image

Examples

preparation example Construction

[0020] A heavy metal ion adsorption membrane and a preparation method thereof, comprising the following steps:

[0021] (1) Preparation of Acetobacter xylinum medium (g / L): glucose 10, peptone 10, yeast powder 7.5, Na 2 HPO 4 10, pH 6.0, pasteurized.

[0022] (2) First activate Gluconoacetobacter xylinum, then inoculate the seed liquid into the culture medium according to the inoculation amount of 3% by volume, put it into a 30°C constant temperature incubator and cultivate it for 6 days, then take out the cellulose film and wash it with water After rinsing, the cellulose membrane was put into a pot and boiled for 15 minutes, and the operation was repeated until the pH was close to neutral to obtain a purified bacterial cellulose membrane.

[0023] (3) Place the bacterial cellulose membrane obtained after culturing for six days in distilled water, and add 0.01 mol and 0.02 mol of cationic etherification agent dropwise into the distilled water respectively at 60° C., and then...

Embodiment 1

[0029] (1) Preparation of Acetobacter xylinum medium (g / L): glucose 10, peptone 10, yeast powder 7.5, Na 2 HPO 4 10, pH 6.0, pasteurized.

[0030] (2) First activate Gluconoacetobacter xylinum, then inoculate the seed liquid into the culture medium according to the inoculation amount of 3% by volume, put it into a 30°C constant temperature incubator and cultivate it for 6 days, then take out the cellulose film and wash it with water After rinsing, the cellulose membrane was put into a pot and boiled for 15 minutes, and the operation was repeated until the pH was close to neutral to obtain a purified bacterial cellulose membrane.

[0031] (3) The bacterial cellulose membrane obtained by culturing for six days was placed in distilled water. At 60° C., 0.01 mol of cationic etherification agent was added dropwise to the distilled water, and then reacted for 12 hours.

[0032] (4) dissolving chitosan in acetic acid solution to form a chitosan acetic acid solution with a concentr...

Embodiment 2

[0037] (1) Preparation of Acetobacter xylinum medium (g / L): glucose 10, peptone 10, yeast powder 7.5, Na 2 HPO 4 10, pH 6.0, pasteurized.

[0038] (2) First activate Gluconoacetobacter xylinum, then inoculate the seed liquid into the culture medium according to the inoculation amount of 3% by volume, put it into a 30°C constant temperature incubator and cultivate it for 6 days, then take out the cellulose film and wash it with water After rinsing, the cellulose membrane was put into a pot and boiled for 15 minutes, and the operation was repeated until the pH was close to neutral to obtain a purified bacterial cellulose membrane.

[0039] (3) The bacterial cellulose membrane obtained by culturing for six days was placed in distilled water. At 60° C., 0.01 mol of cationic etherification agent was added dropwise to the distilled water, and then reacted for 12 hours.

[0040] (4) dissolving chitosan in acetic acid solution to form a chitosan acetic acid solution with a concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com