Preparation method for anticorrosive and insulative plating layer of neodymium-iron-boron permanent magnet and neodymium-iron-boron permanent magnet with plating layer

An anti-corrosion insulation, NdFeB technology, applied in the manufacture of permanent magnets, inductors/transformers/magnets, coatings, etc. Magnetic flux reduction and other problems, to achieve good anti-corrosion performance and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

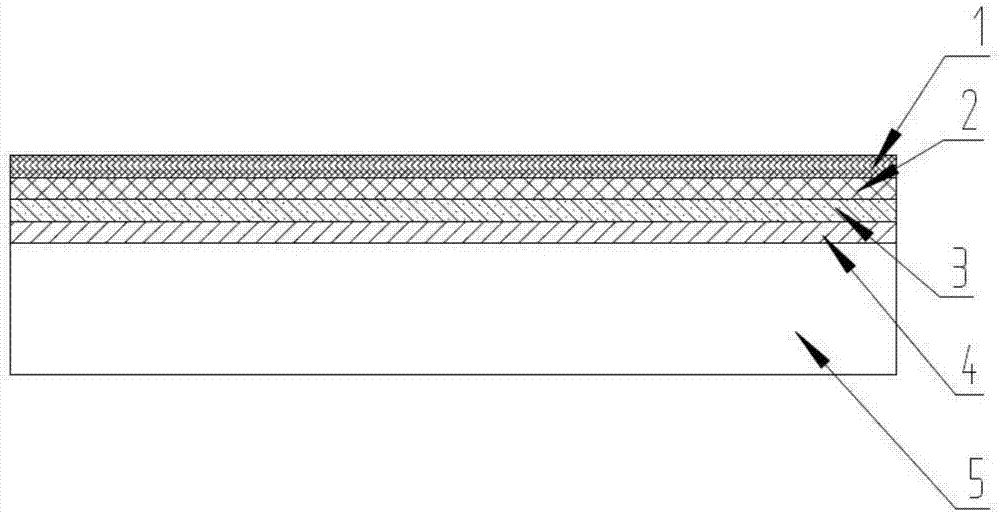

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a method for preparing an NdFeB permanent magnet anti-corrosion insulating coating, comprising the following steps:

[0027] S1 surface pretreatment: Clean the surface of semi-finished NdFeB permanent magnets, remove pollutants and dry them.

[0028] In this step, the pollutants on the surface of the NdFeB permanent magnet, especially grease, etc. are removed by cleaning, which is beneficial to the subsequent coating. It should be noted that when cleaning, the standard is to remove the surface pollutants.

[0029] Further, drying is carried out after cleaning in this step, which can remove the moisture inside the NdFeB permanent magnet and avoid affecting the anti-corrosion effect. It should be noted that when drying, it is advisable to choose a drying temperature of 50°C-120°C, for example: the drying temperature can be 50°C, 60°C, 70°C, 80°C, 90°C, 100°C, 110°C , 120°C, etc. This is because: the drying temperature is ...

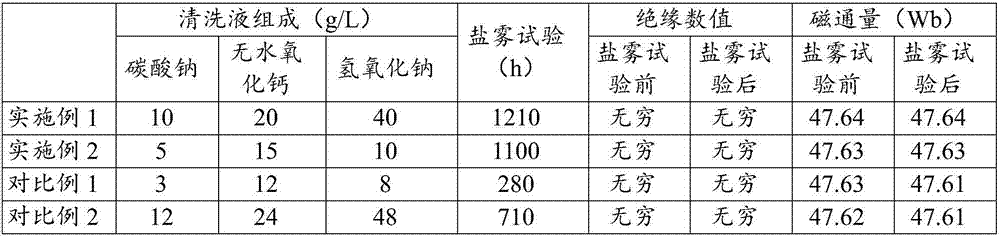

Embodiment 1

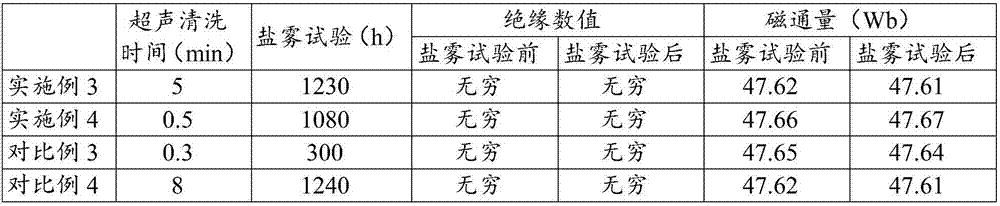

[0052] S1 surface pretreatment: put the semi-finished NdFeB permanent magnet in the cleaning solution for 5 minutes, the composition of the cleaning solution is: sodium carbonate 10g / L, anhydrous calcium oxide 20g / L, sodium hydroxide 40g / L, the solvent is water Take it out after cleaning, rinse with 10us / cm deionized water for 1min; take it out after rinsing, place it in an ultrasonic cleaner for ultrasonic cleaning for 5min, the pH value of the ultrasonic water is 6.5; take it out after ultrasonic cleaning, use 10us / cm deionized water Ionized water is used for secondary rinsing, and the rinsing time is 1 min; take it out and put it in a drying oven at 80°C for 5 min.

[0053] S2 surface activation: place the dried NdFeB permanent magnet in the ion activation area of the vacuum coating machine, the vacuum degree of the ion activation area is 1Pa, and use an ion source with a power of 3kW to activate the surface of the NdFeB permanent magnet , The activation time is 3min.

[0...

Embodiment 2

[0056] The difference from Example 1 is that the cleaning solution used during surface pretreatment consists of: sodium carbonate 5g / L, anhydrous calcium oxide 15g / L, sodium hydroxide 10g / L, and the solvent is water. Except for the composition of the cleaning solution, other steps and operating conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com