Nanoporous magnesium silicate microsphere/PBS (poly(butylene succinate)) composite scaffold, composite scaffold coated with protein, preparation methods and application

A polybutylene succinate and composite scaffold technology, which is applied in coatings, pharmaceutical formulations, and medical sciences, can solve problems such as slow bone regeneration and osseointegration, poor osteogenic differentiation, and slow cell response. Achieve the effects of promoting proliferation, good compatibility, and increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

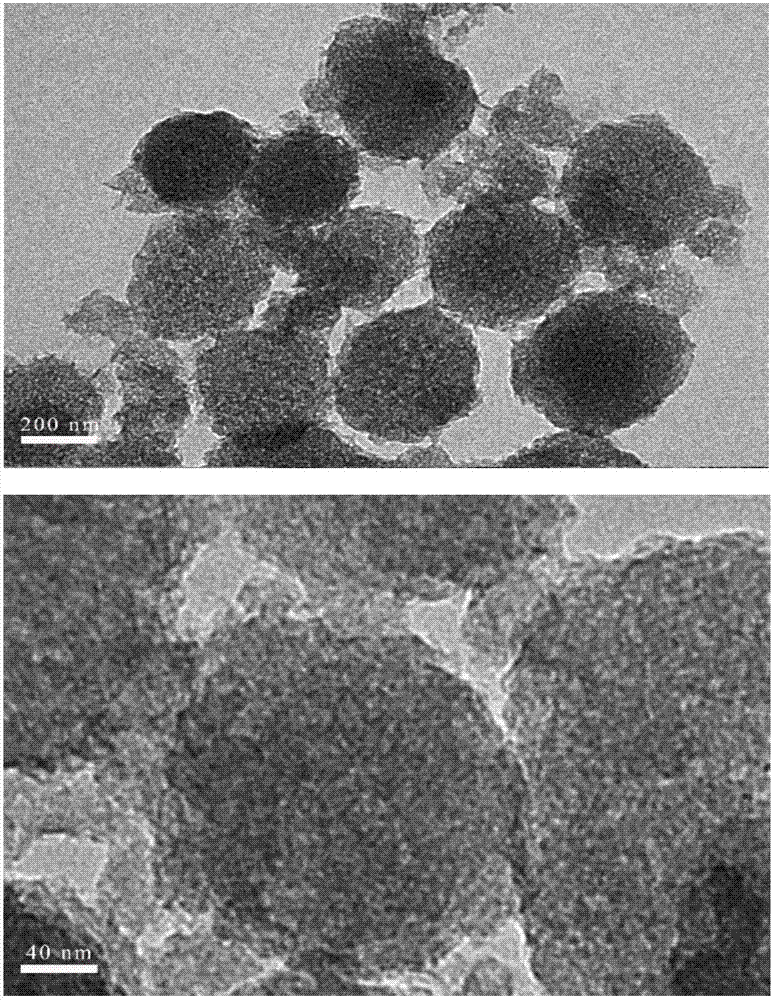

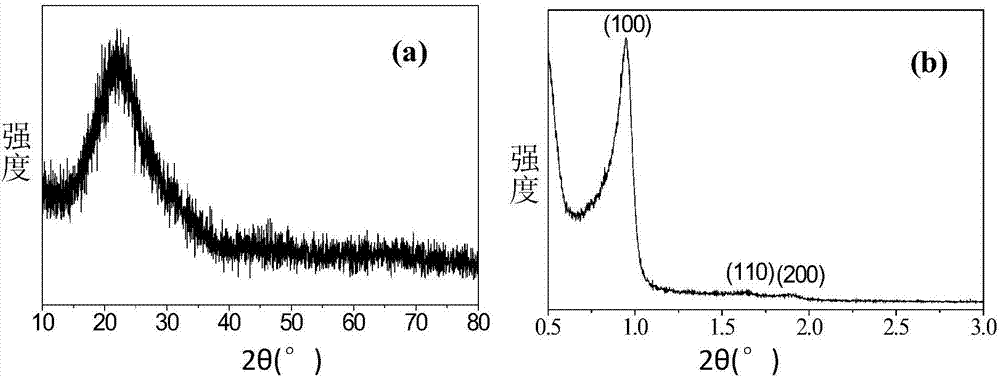

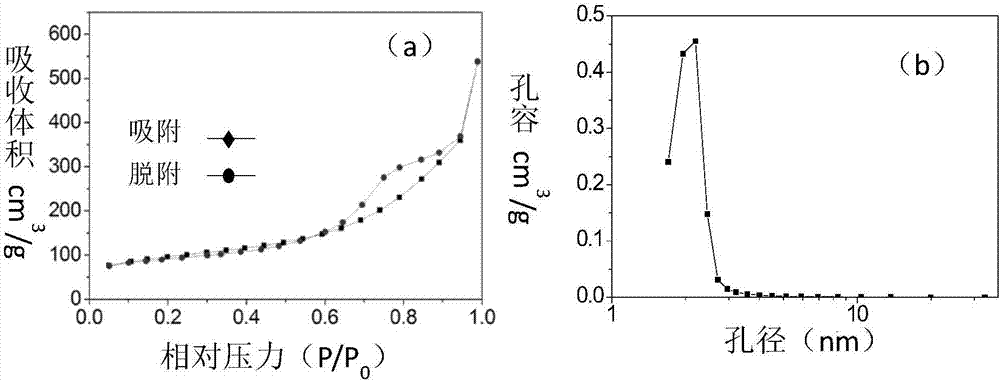

[0088] (1) Preparation of nanoporous magnesium silicate microspheres (NMS)

[0089] Accurately weigh 0.7 g of cetyltrimethylammonium bromide (CTAB) and dissolve it in 33 mL of deionized water, and place it in a constant temperature water bath at 35°C. After CTAB was completely dissolved, 7 mL of 1 mol / L ammonia water, 3.6 mL of tetraethyl orthosilicate (TEOS) and 2.47 g of magnesium nitrate hexahydrate were added in sequence. After fully reacting for 4 hours, the solution turned into a milky white suspension, and a white precipitate was collected after centrifugation. After washing twice with alcohol and once with deionized water, place it in an electric blast drying oven at 60°C for 24 hours and dry it. Finally, the obtained product was placed in a muffle furnace, sintered at 600° C., kept for 3 hours, CTAB was removed, and a white powder was obtained, namely NMS.

[0090] (2) Preparation of nanoporous magnesium silicate microspheres / polybutylene succinate composite scaffol...

Embodiment 2

[0099] (1) Preparation of nanoporous magnesium silicate microspheres (NMS)

[0100] Accurately weigh 0.6g of cetyltrimethylammonium bromide (CTAB) and dissolve it in 31mL of deionized water, and place it in a constant temperature water tank at 33°C. After CTAB was completely dissolved, 8 mL of 0.5 mol / L ammonia water, 3.4 mL of tetraethyl orthosilicate (TEOS) and 2.40 g of magnesium nitrate hexahydrate were sequentially added. After fully reacting for 3 hours, the solution turned into a milky white suspension, and a white precipitate was collected after centrifugation. After washing twice with alcohol and once with deionized water, place it in an electric blast drying oven at 50°C for 26 hours and dry it. Finally, the obtained product was placed in a muffle furnace, sintered at 500° C., kept for 4 hours, CTAB was removed, and a white powder was obtained, namely NMS.

[0101] (2) Preparation of nanoporous magnesium silicate microspheres / polybutylene succinate composite scaffo...

Embodiment 3

[0110] (1) Preparation of nanoporous magnesium silicate microspheres (NMS)

[0111] Accurately weigh 0.8g of cetyltrimethylammonium bromide (CTAB) and dissolve it in 33mL of deionized water, and place it in a constant temperature water tank at 35°C. After CTAB was completely dissolved, 8 mL of 1.5 mol / L ammonia water, 3.8 mL of tetraethyl orthosilicate (TEOS) and 2.54 g of magnesium nitrate hexahydrate were sequentially added. After fully reacting for 5 hours, the solution turned into a milky white suspension, and a white precipitate was collected after centrifugation. After washing twice with alcohol and once with deionized water, place it in an electric blast drying oven at 70°C for 22 hours and dry it. Finally, the obtained product was placed in a muffle furnace, sintered at 700° C., kept for 2 hours, CTAB was removed, and a white powder was obtained, namely NMS.

[0112] (2) Preparation of nanoporous magnesium silicate microspheres / polybutylene succinate composite scaffold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com