Method for preparing diamond film on stainless steel surface

A technology of diamond thin film and stainless steel, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of film shedding, difficult formation of diamond film, and large difference in thermal expansion coefficient of diamond. The effect of improving conductivity, relieving stress, and increasing nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Use a sandblasting machine (XL-S-9060 / 1A, Shanghai Xufeng Machinery Equipment Co., Ltd.) to sandblast the surface of the 3Cr13 martensitic stainless steel sample. The sandblasting parameters are as follows: time 10min, sand is 80 mesh glass sand, working pressure is 0.3MPa, the roughness of the sample after blasting is R a = 2 μm.

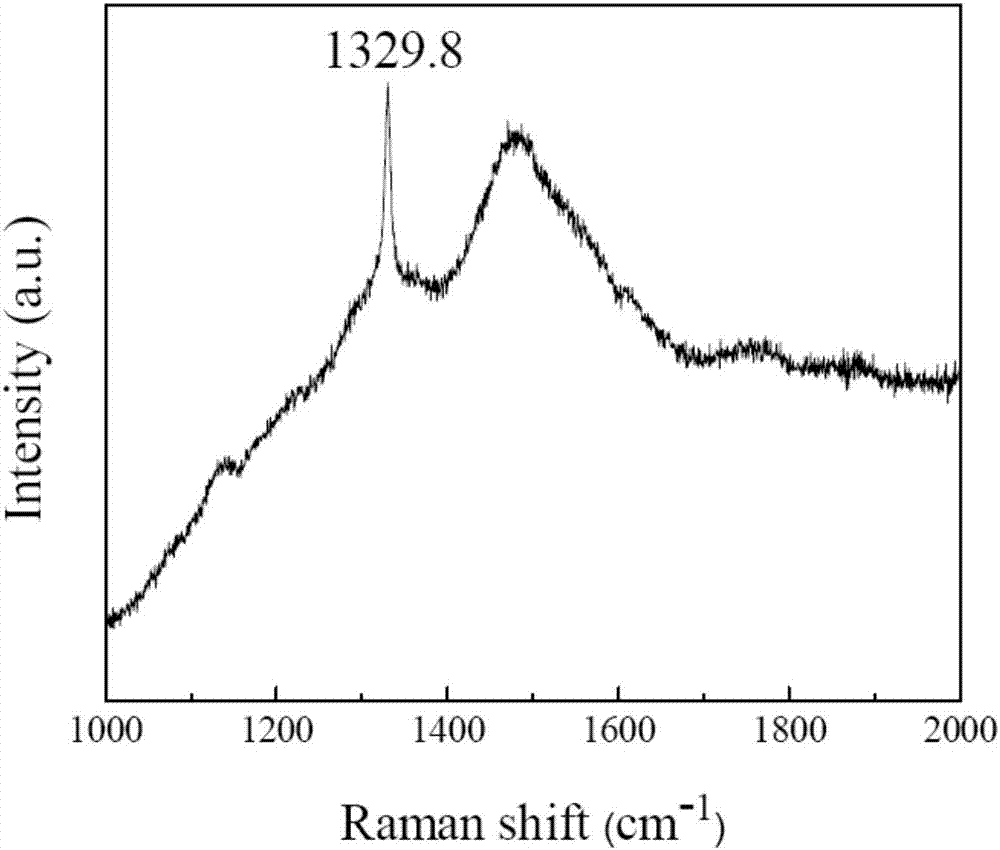

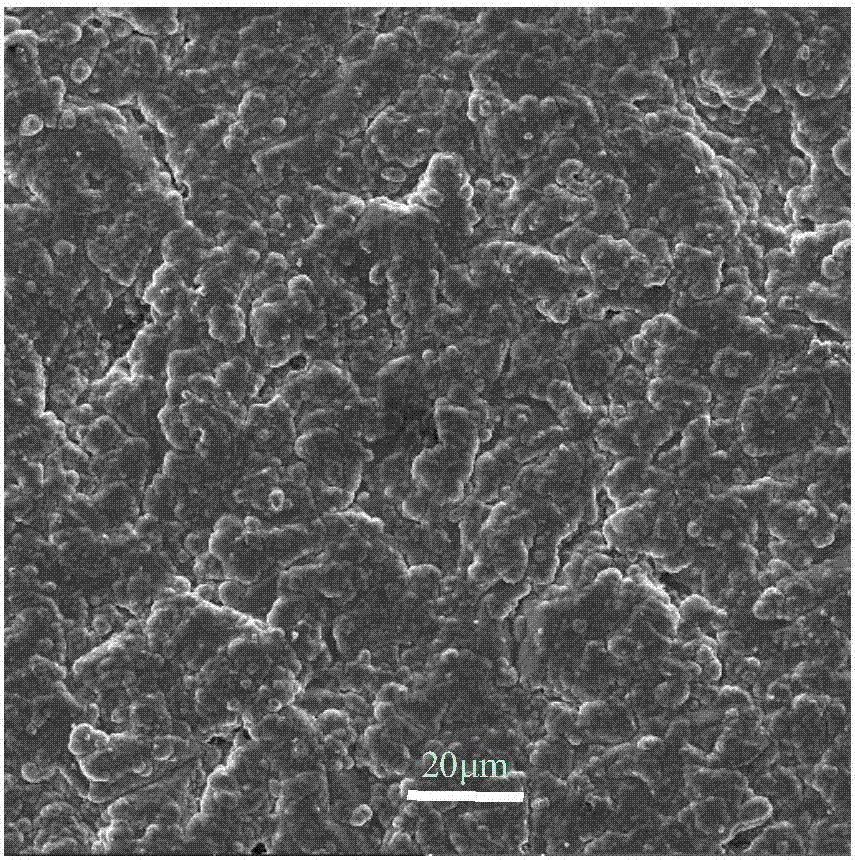

[0033] After sandblasting, use acetone and ethanol to ultrasonically clean for 20 minutes respectively, and blow dry. Then use an unbalanced magnetron sputtering apparatus udp650 to deposit Cr / CrN / CrTiAlN coating on it. The specific process parameters are: when sputtering the Cr layer, the Cr target power is 4.4kW, and the time is 5min; when sputtering the CrN layer, The power of Cr target is 4.4kW, the time is 20min, the flow ratio of nitrogen and argon is 0.93; when sputtering CrTiAlN, the power of Cr target is 4.4kW, the power of Ti target is 8kW, the power of Al target is 8kW, and the deposition time is 50min. The film was detected by ...

Embodiment 2

[0039]Use a sandblasting machine (XL-S-9060 / 1A, Shanghai Xufeng Machinery Equipment Co., Ltd.) to blast the surface of 304 austenitic stainless steel samples. The sandblasting parameters are as follows: time 2min, sand is 50 mesh glass sand, working pressure is 0.05MPa.

[0040] After sandblasting, use acetone and ethanol to ultrasonically clean for 20 minutes respectively, and blow dry. Then use unbalanced magnetron sputtering apparatus udp650 to deposit Cr / CrN / CrTiAlN coating on it. The process parameters are: when sputtering Cr layer, the Cr target power is 4.4kW, and the time is 8min; when sputtering CrN layer, Cr The target power is 4.4kW, the time is 30min, the flow ratio of nitrogen and argon is 0.93; when sputtering CrTiAlN, the Cr target power is 4.4kW, the Ti target power is 6kW, the Al target power is 6kW, and the deposition time is 100min. The film was detected by a ball pit instrument (BC-2, Teer Coating Company), and the total thickness of the film was 4 μm, the...

Embodiment 3

[0046] Use a sandblasting machine (XL-S-9060 / 1A, Shanghai Xufeng Machinery Equipment Co., Ltd.) to sandblast the surface of 0Cr13 ferritic stainless steel samples. The sandblasting parameters are as follows: time 20min, sand is 220 mesh glass sand, working pressure is 0.6MPa.

[0047] After sandblasting, use acetone and ethanol to ultrasonically clean for 20 minutes respectively, and blow dry. Then use an unbalanced magnetron sputtering instrument udp650 to deposit CrTiAlN coating on it. The process parameters are: when sputtering Cr layer, the Cr target power is 4.4kW, and the time is 10min; when sputtering CrN layer, the Cr target power is 4.4 kW, the time is 40min, the flow ratio of nitrogen and argon is 0.93; when sputtering CrTiAlN, the Cr target power is 4.4kW, the Ti target power is 1kW, the Al target power is 1kW, and the deposition time is 160min. The film was detected by ball pit instrument (BC-2, Teer coating company), and its total thickness was 5 μm, the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com