A kind of preparation method of aviation kerosene or diesel oil

A technology of aviation kerosene and diesel oil, which is applied in the field of preparation of aviation kerosene or diesel oil, which can solve the problems of high requirements for production equipment, limited raw materials, complicated process, etc., and achieve the effects of easy recycling, low price, and widening the synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

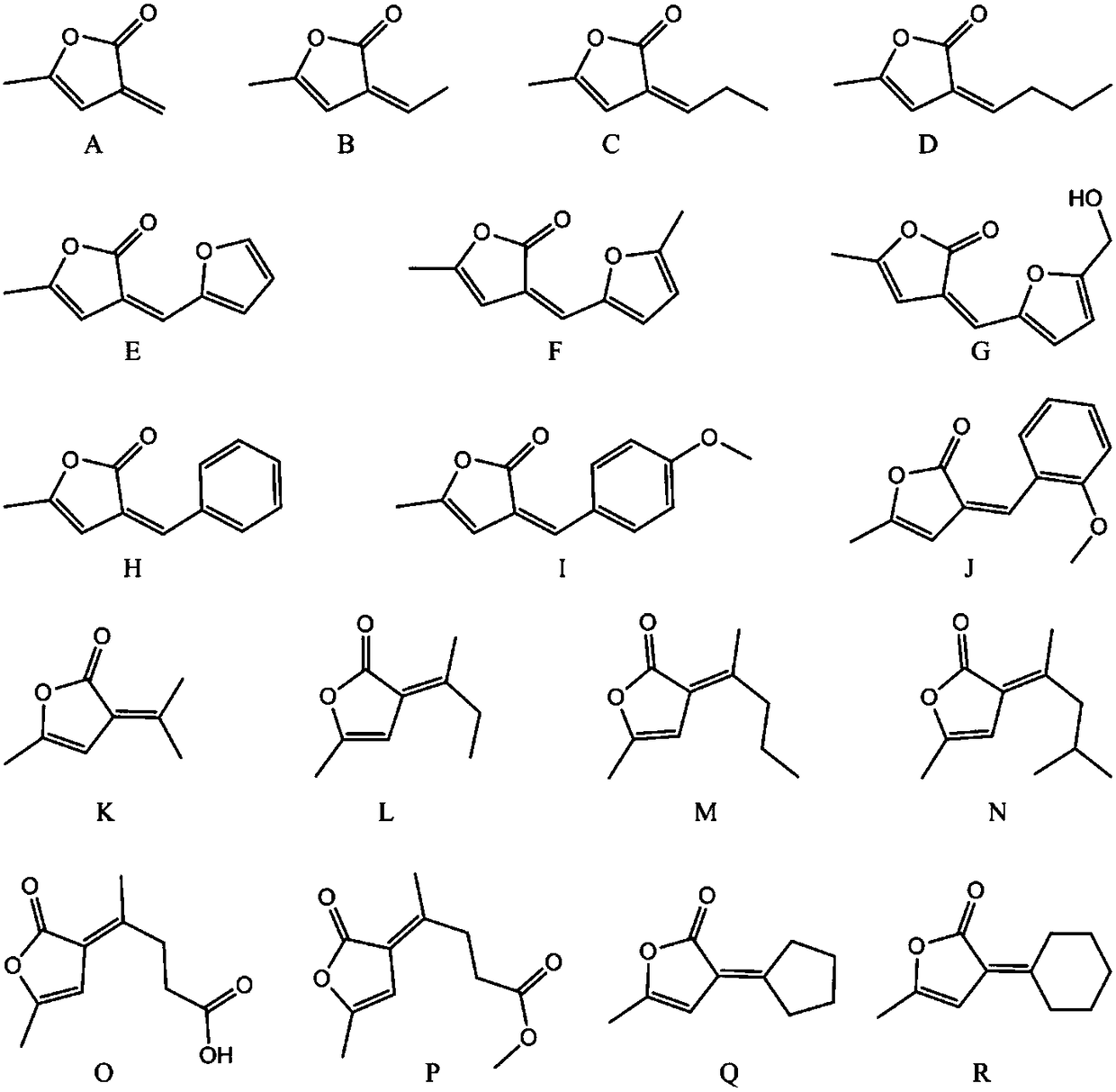

Method used

Image

Examples

Embodiment

[0038] 1. Preparation of catalyst:

[0039] 1) Metal oxide catalysts: calcium oxide, magnesium oxide, zinc oxide, manganese dioxide, lanthanum pentoxide, ferric oxide, copper oxide, titanium dioxide, tin dioxide, niobium pentoxide, zirconium dioxide, trioxide One or more mixtures of dichromium, aluminum oxide, molybdenum trioxide, and ceria are directly purchased commercial catalyst products, which are calcined at 500°C for 4 hours before use. The ionic liquid is prepared according to the method reported in the literature, and the specific method is as follows:

[0040] Weigh 15mmol of organic amine compounds (secondary amines such as primary amines such as methylamine, ethylamine, propylamine, isopropylamine, butylamine, and aniline, secondary amines such as dimethylamine, diethylamine, dipropylamine, diisopropylamine, and di-n-butylamine, One of organic amine compounds such as cyclic primary amines such as tetrahydropyrrole and hexahydropyridine, tertiary amines such as tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com