Heat dissipation device of mobile cabinet level server system and thermal management method of heat dissipation device

A technology of server system and heat dissipation device, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment construction parts, etc., which can solve the problems of large initial investment in data centers, large impact on office environment, and low resource utilization. To achieve the effect of improving reliability, low cost and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

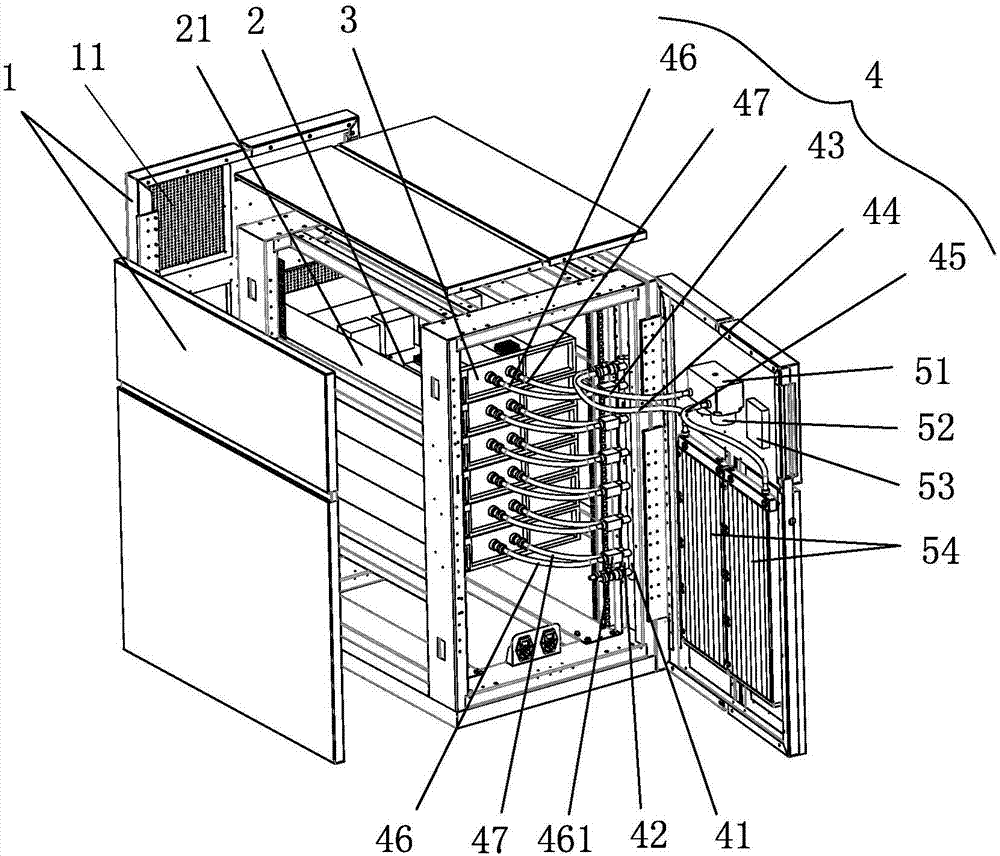

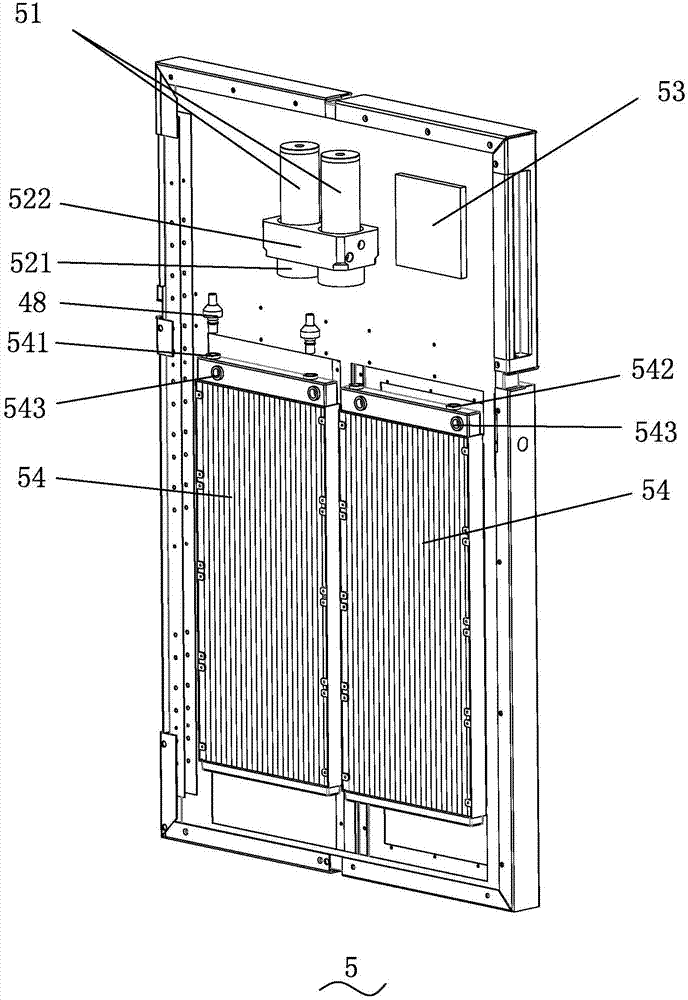

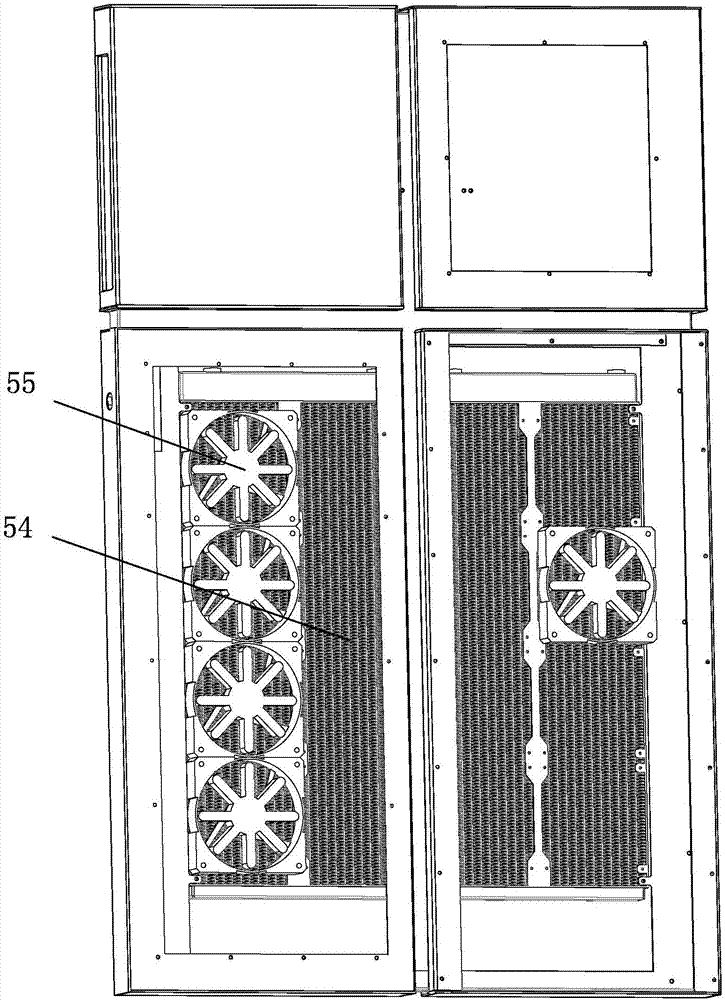

[0036] Such as Figure 1 to Figure 6 As shown, a heat dissipation device for a mobile cabinet-level server system includes water-cooled heat pipes installed in the mobile cabinet 1 to dissipate heat from UPS power supplies, switches, routers, firewall servers, CPUs, memory, north bridges, hard disks, and power supplies. Module 3, pipeline system 4, rear door heat dissipation device 5 and control system, each electronic device 2 in the mobile cabinet 1 that needs heat dissipation corresponds to a water-cooled heat pipe heat dissipation module 3, and the water-cooled heat pipe heat dissipation module 3 is used from The electronic equipment 2 absorbs heat, and several water-cooled heat pipe cooling modules 3 are connected to the rear door cooling device 5 through the pipeline system 4. The rear door cooling device 5 includes a water pump 52, a cold row 54 and a fan arranged on the cabinet door of the mobile cabinet 1. 55, the fan 55 is aligned with the cold row 54, and the water ...

Embodiment 2

[0046] The basic structure of this embodiment is the same as that of Embodiment 1, and its similarity with Embodiment 1 will not be repeated here. The difference between it and Embodiment 1 is:

[0047] In embodiment 2, only water pump 52 part is different from embodiment 1, and other parts are all the same, as Figure 7 As shown, in Embodiment 2, the dual water pumps 52 are connected in series, and the dual water pumps 52 are connected in series to drive the entire cycle operation. When the double water pumps 52 are connected in series, the water tank 51 and the water pump 52 adopt an integrated design. At the same time, when the double water pumps 52 are connected in series, there is only one inlet and one outlet. The interface is connected.

Embodiment 3

[0049] The basic structure of this embodiment is the same as that of Embodiment 1, and its similarity with Embodiment 1 will not be repeated here. The difference between it and Embodiment 1 is:

[0050] A cooling device for a mobile rack-level server system, the control system includes a temperature control system and an industrial control system, the temperature control system includes a temperature sensing device, the temperature sensing device is used to sense the temperature of liquid refrigerant, and the temperature control system sends a signal to the industrial control system according to the temperature system, the industrial control system controls the flow regulating device to adjust the flow rate of the refrigerant and the speed of the fan 55 .

[0051] A heat management method for a cooling device of a mobile cabinet-level server system. The temperature control system is controlled by feedback. When the temperature of the liquid refrigerant in the circulation system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com