Graphene composite conductive powder and preparation method thereof

A graphene composite, conductive powder technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as hindering synergy, low energy consumption, and reducing the conductivity of three-dimensional conductive networks, achieving easy operation and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

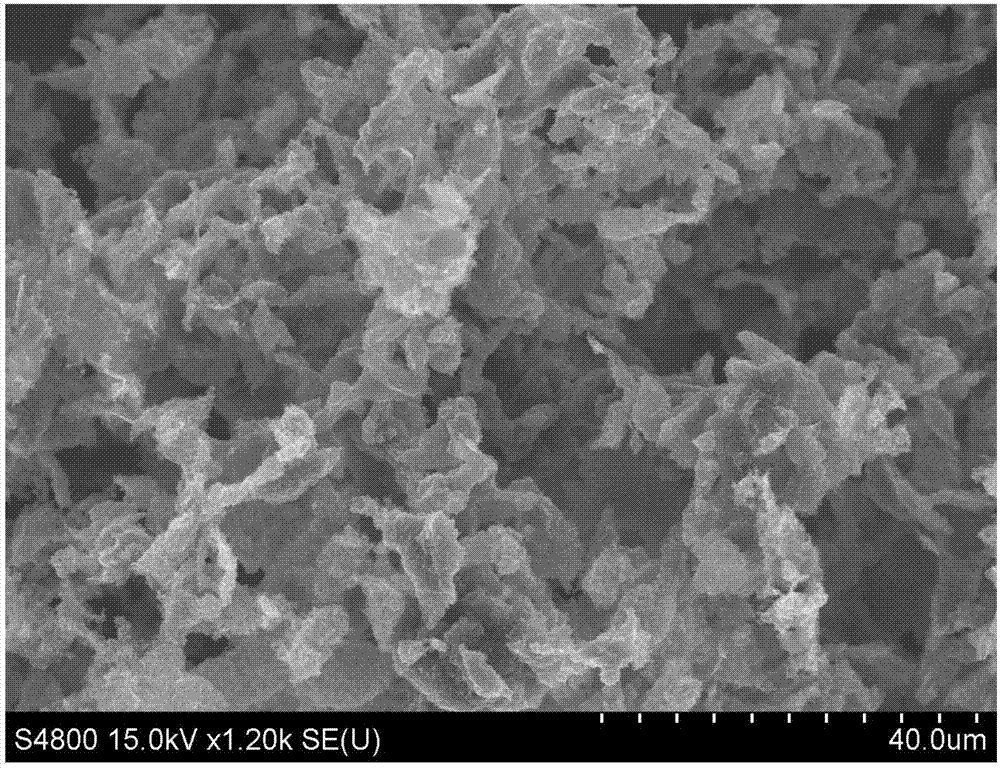

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of graphene composite conductive powder, which comprises the following steps:

[0029] S1, dissolving conductive carbon material, monomer, initiator, and dopant in an aqueous solution and mixing them uniformly, and obtaining a polymer composite material through in-situ polymerization;

[0030] S2, respectively dispersing the polymer composite material and the graphene material in water, mixing uniformly, and obtaining a graphene composite conductive paste through π-π conjugation; and

[0031] S3, drying the graphene composite conductive paste to obtain graphene composite conductive powder.

[0032] In step S1, the monomer is at least one of aniline, pyrrole and thiophene. The initiator is at least one of ferric chloride, ammonium persulfate and potassium persulfate. The dopant is hydrochloric acid, H 2 SO 4 and at least one of sodium dodecylbenzenesulfonate.

Embodiment 1

[0048] (1) Under the condition of ice-water bath, add 150ml 1mol / L hydrochloric acid solution, 9.312g aniline and 46.56g conductive carbon black (SP) into the flask and mix well, add dropwise 100mL aqueous solution containing 22.818g ammonium persulfate as polymerization reaction The initiator was stirred and reacted in the dark for 24 hours, then filtered, washed and dried to obtain a polymer composite material.

[0049] (2) Disperse the above-mentioned polymer composite material and graphene material in water according to the mass ratio of 1:1, configure a mixed solution with a mass fraction of 3%, stir and disperse the mixed solution evenly, and obtain self-assembled graphene / SP composite conductive Slurry, finally add ammonium carbonate to the mixed solution, the mass ratio of ammonium carbonate to graphene material is 1:20, stir and disperse evenly.

[0050] (3) Spray-dry the above-mentioned graphene / SP composite conductive paste, the air inlet temperature of spray drying...

Embodiment 2

[0054] (1) Under ice-water bath conditions, add 150ml 1mol / L hydrochloric acid solution, 9.312g aniline and 4.656g conductive carbon black SP into the flask and mix evenly, and dropwise add 100mL aqueous solution containing 22.818g ammonium persulfate as the initiation of the polymerization reaction agent, stirred and reacted in the dark for 24 hours, filtered, washed, and dried to obtain a polymer composite material.

[0055] (2) Disperse the graphene material and the above-mentioned polymer composite material in water according to the mass ratio of 1:0.1, configure a mixed solution with a mass fraction of 2%, stir and disperse the mixed solution evenly, and obtain a self-assembled graphene / SP composite conductive Slurry, finally add ammonium oxalate to the mixed solution, the mass ratio of ammonium oxalate to graphene material is 1:10, stir and disperse evenly.

[0056] (3) The above-mentioned graphene / SP composite conductive paste is spray-dried, the air inlet temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com