Junction barrier Schottky diode with composite dielectric layer structure

A technology of junction barrier Schottky and composite dielectric, which is applied in the field of junction barrier Schottky diodes, can solve the problems that the breakdown voltage cannot reach the limit of GaN materials, the reverse leakage current is low, and the difficulty of increasing production is achieved. Avoid the Schottky barrier lowering effect, reduce the reverse leakage current, and optimize the effect of electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

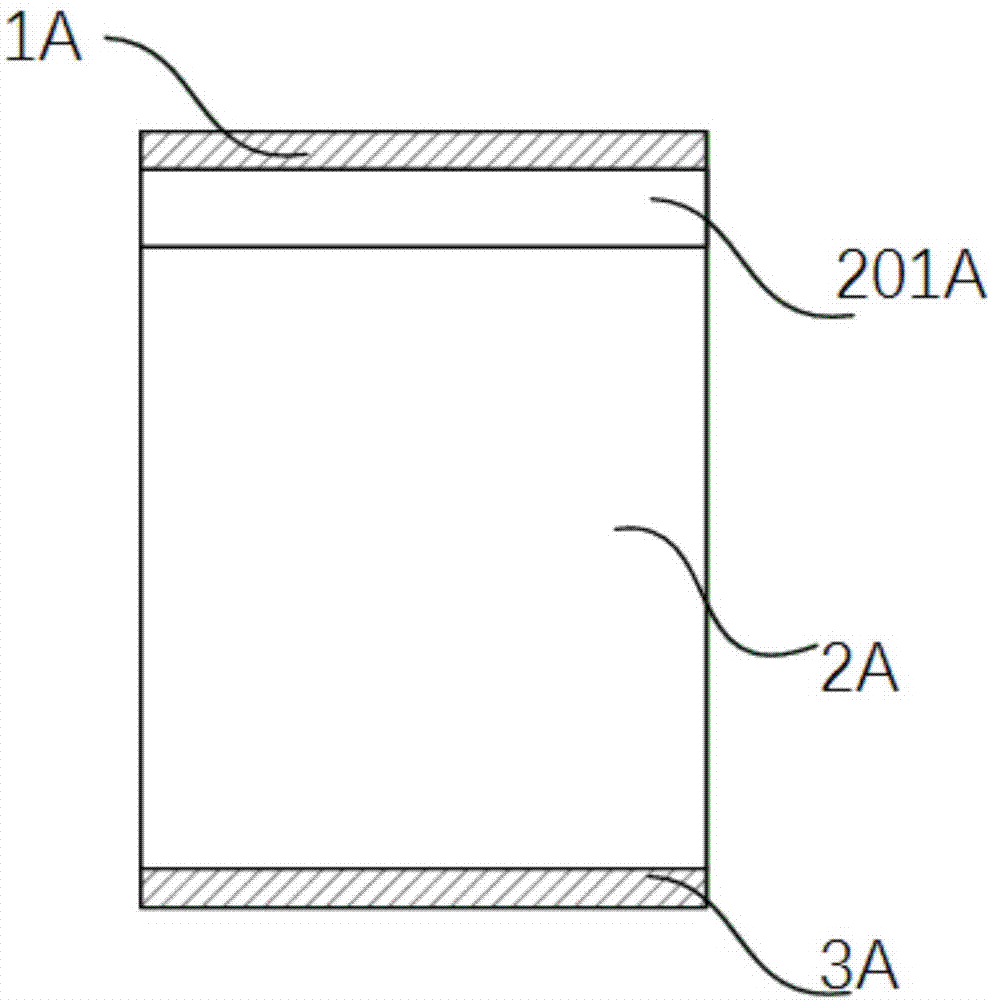

[0056] Such as Figure 4 As shown, the embodiment of the present invention provides a gallium nitride-based junction barrier Schottky diode with a composite dielectric layer structure (hereinafter abbreviated as HLKP JBS in this embodiment), and its cell structure sequentially includes from top to bottom: The metal anode 1, the N-type material layer 2 and the metal cathode 4, the upper layer of the N-type material layer 2 respectively has at least two mutually independent P-type doped regions 201; wherein, the metal anode 1 and the P-type doped region 201 An ohmic contact is formed on the surface, and both the metal anode 1 and the metal cathode 4 form Schottky contact with the N-type material layer 2; the doping concentration range of the N-type material layer 2 in this embodiment is 5×10 15 ~1×10 16 cm -3 ,

[0057] The present invention does not limit the shape of the N-type material layer 2, usually a rectangular parallelepiped. There are n mutually independent P-type doped re...

Embodiment 2

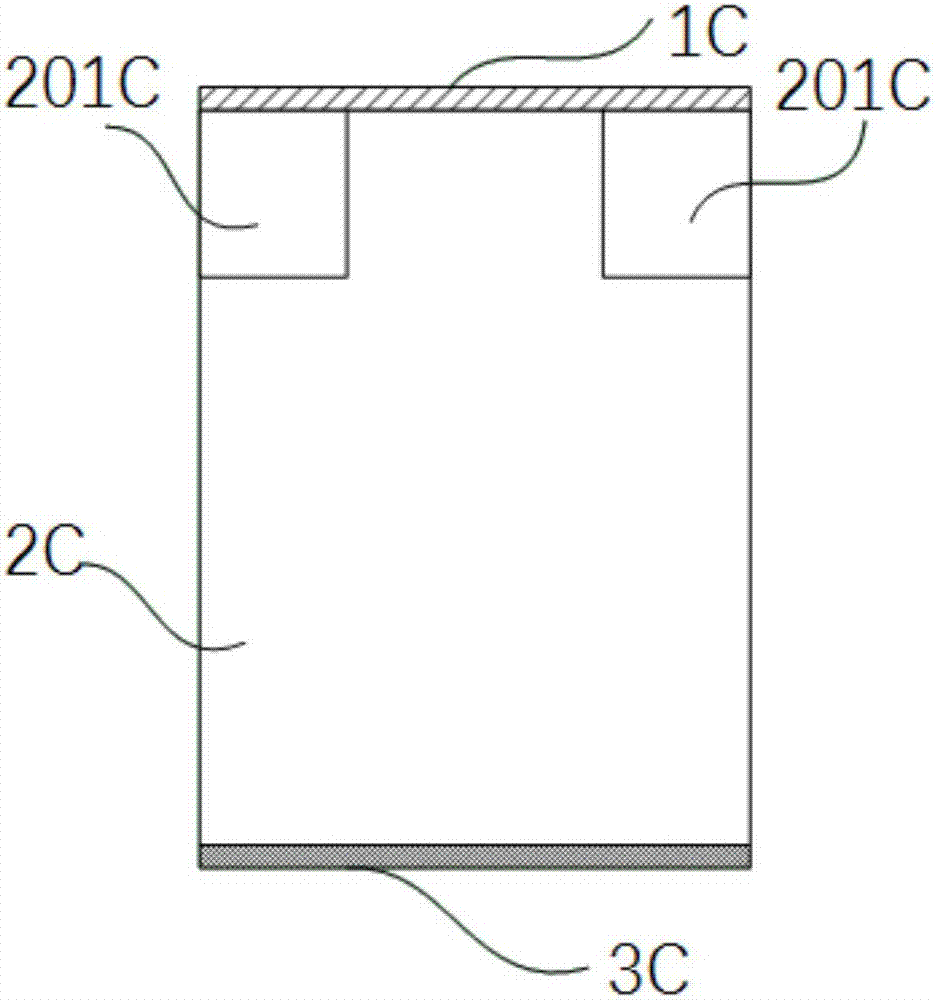

[0077] Combine Picture 10 with Picture 11 The present invention provides a gallium nitride-based junction barrier Schottky diode with a composite dielectric layer structure (hereinafter abbreviated as HLKP JBS in this embodiment). The device structure of this embodiment is in addition to the configuration and implementation of the composite dielectric layer 3. Except for the difference in Example 1, the rest of the structure is the same, so it will not be repeated here; however, in the device structure of this embodiment, the composite dielectric layer 3 is still symmetrically arranged on and in contact with the outer walls on both sides of the N-type material layer 2, which is the same as in Example 1. The difference is that the N-type material layer 2 and its P-type doped region 201 are only in contact with the same dielectric material. Specifically, the composite dielectric layer 3 on each side is composed of a third dielectric region 303 and a fourth dielectric region. 304...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com