Method for obtaining fine primary alpha-Al equiaxed grains in zinc-aluminum alloy

A technology of equiaxed grains and aluminum alloys, applied in the field of alloy materials, can solve the problems of limited grain refinement effect of primary α-Al and weakened grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

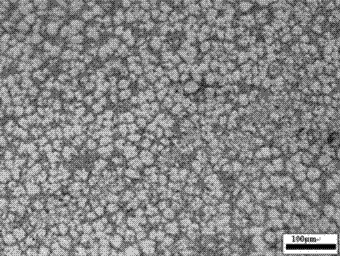

Embodiment 1

[0026] In the Zn-34 wt.%Al alloy (the mass percentage of Zn in the alloy is 66%, the mass percentage of Al is 34%, and the wt.% is omitted below, that is, Zn-34Al) (the liquidus temperature is 530°C) The method for obtaining spherical or polyhedral fine primary α-Al equiaxed grains, the steps are as follows:

[0027] Step S110, preparing Zn-31.9Al-6Ce-0.3Mg master alloy, the steps are as follows:

[0028] Step S111, mixing pure Zn, pure Al, pure Mg and Al-20Ce master alloy to obtain a Zn-Al-Ce-Mg mixed raw material, wherein the mass ratio of Zn and Al in the Zn-Al-Ce-Mg mixed raw material is equal to The mass ratio (66:34) of Zn and Al in Zn-Al alloy is the same.

[0029] Step S112, put the Zn-Al-Ce-Mg mixed raw material in a crucible, heat it to 700-750°C and melt it completely, keep it warm for 15-30 minutes, then stir it fully, pour it into a mold, and cool it to get Zn-31.9 Al-6Ce-0.3Mg master alloy.

[0030] In step S120, a Zn-32Al-6Zr master alloy is prepared accordin...

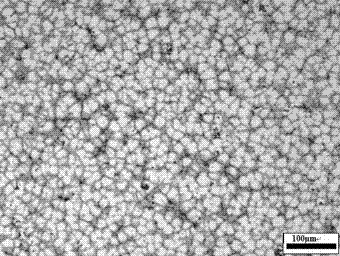

Embodiment 2

[0035] The method for obtaining spherical or polyhedral fine primary α-Al equiaxed grains in Zn-34Al alloy (liquidus temperature is 530°C), the steps are as follows:

[0036] Step S210, preparing Zn-31.9Al-6Ce-0.3Mg master alloy, the preparation steps are the same as the method provided in Example 1, and will not be repeated here.

[0037] In step S220, a Zn-32Al-6Zr master alloy is prepared according to the prior art, which will not be repeated here.

[0038] Step S230, melting the Zn-34Al alloy to 700° C. to obtain a Zn-34Al alloy melt.

[0039] In step S240, simultaneously add the Zn-31.9Al-6Ce-0.3Mg master alloy prepared in step S210 and the Zn-32Al-6Zr master alloy prepared in step S220 into the Zn-34Al alloy melt, and continue to keep warm for 8-20 minutes, fully Stir to make Zr, Ce, and Mg elements evenly distribute in the Zn-34Al alloy melt to obtain the final alloy melt, wherein the contents of Zr, Ce, and Mg elements in the final alloy melt are 0.1wt.%, 0.1wt.%, res...

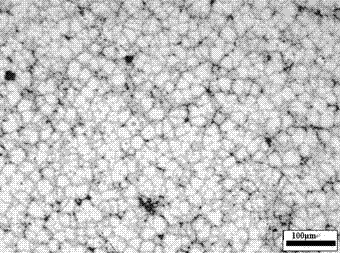

Embodiment 3

[0042]The method for obtaining spherical or polyhedral fine primary α-Al equiaxed grains in Zn-34Al alloy (liquidus temperature is 530°C), the steps are as follows:

[0043] In step S310 , preparing a Zn-31.9Al-6Ce-0.3Mg master alloy, the preparation steps are the same as the method provided in Example 1, and will not be repeated here.

[0044] In step S320, a Zn-32Al-6Zr master alloy is prepared according to the prior art, which will not be repeated here.

[0045] Step S330, melting the Zn-34Al alloy to 700° C. to obtain a Zn-34Al alloy melt.

[0046] In step S340, the Zn-31.9Al-6Ce-0.3Mg master alloy prepared in step S310 and the Zn-32Al-6Zr master alloy prepared in step S320 are simultaneously added to the Zn-34Al alloy melt, and the heat preservation is continued for 8-20 minutes, fully Stir to make the Zr, Ce, and Mg elements evenly distributed in the Zn-34Al alloy melt to obtain the final alloy melt, wherein the contents of Zr, Ce, and Mg elements in the final alloy mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com