Method for recycling copper and nickel by treating copper and nickel plating sludge through rotational flow electrolysis

A swirl electrolysis and copper recovery technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of cumbersome, complex process, low purity of copper and nickel products, and achieve less reagent consumption, short process flow, and avoid physical problems. health damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

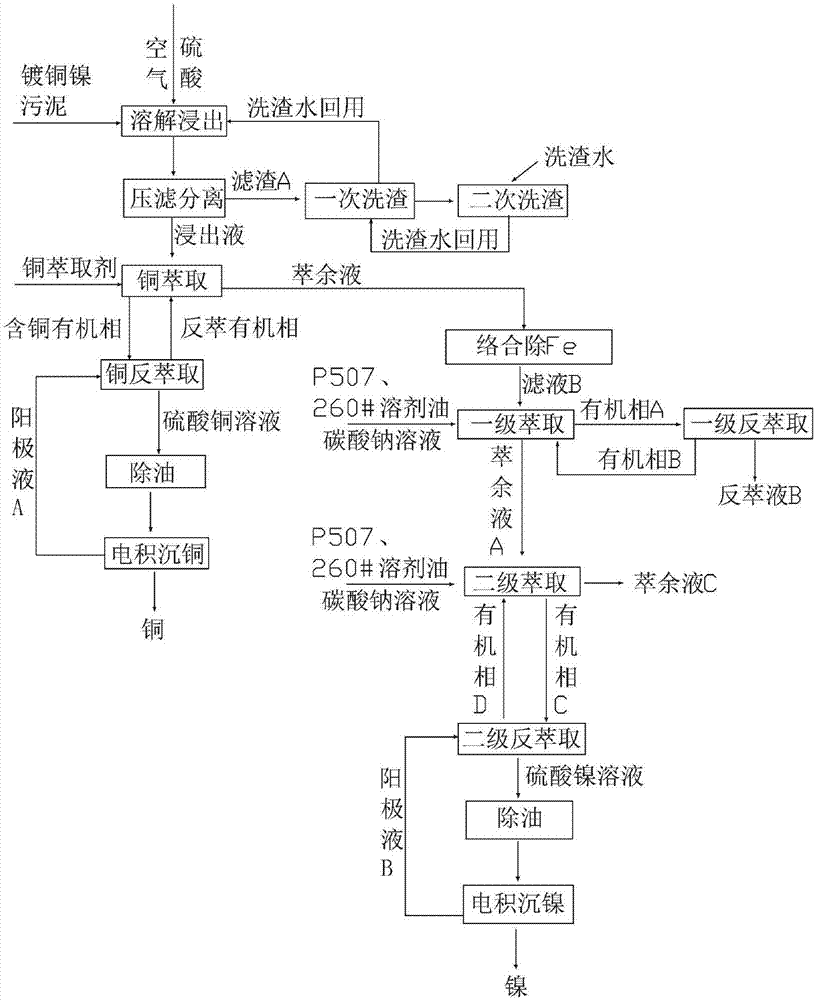

[0032] The method that utilizes cyclone electrolytic treatment copper-nickel sludge of the present embodiment to reclaim copper and nickel comprises the following operations:

[0033] For dissolution and leaching, add copper-plated nickel sludge and water into the dissolution tank at a volume ratio of 1:3 for mixing and slurrying, then slowly add 98% concentrated sulfuric acid dropwise, stir and dissolve at a speed of 500r / min, and at the same time use a flow rate of 0.3 m 3 Blow in oxygen-enriched air per hour, react for 2.5 hours at a temperature of 50°C and a pressure of 0.6 MPa, and control the pH of the reaction end point to 1.5. After the reaction, transfer the obtained leaching slurry into a plate and frame filter press for separation by filtration Obtain leachate and filter residue A1. After pressure filtration, dry the filter residue A1 with compressed air to reduce the water content of the filter residue A1 as much as possible. In order to improve the recovery rate...

Embodiment 2

[0050] The method that utilizes cyclone electrolytic treatment copper-nickel sludge of the present embodiment to reclaim copper and nickel comprises the following operations:

[0051] For dissolution and leaching, add copper-plated nickel sludge and water into the dissolution tank at a volume ratio of 1:4 for mixing and slurrying, then slowly add 98% concentrated sulfuric acid dropwise, stir and dissolve at a speed of 700r / min, and at the same time use a flow rate of 0.6 m 3Blow in oxygen-enriched air per hour, react for 3.5 hours at a temperature of 43°C and a pressure of 0.4 MPa, and control the pH of the reaction end point to 1.0. After the reaction, transfer the obtained leaching slurry into a plate and frame filter press for separation by filtration Obtain leachate and filter residue A2. After press filtration, dry the filter residue A2 with compressed air to reduce the water content of the filter residue A2 as much as possible. In order to improve the recovery rate of ...

Embodiment 3

[0059] The method that utilizes cyclone electrolytic treatment copper-nickel sludge of the present embodiment to reclaim copper and nickel comprises the following operations:

[0060] For dissolution and leaching, add copper-plated nickel sludge and water into the dissolution tank at a volume ratio of 1:4 for mixing and slurrying, then slowly add 98% concentrated sulfuric acid dropwise, stir and dissolve at a speed of 600r / min, and at the same time use a flow rate of 0.5 m 3 Blow in oxygen-enriched air per hour, react for 3.0 hours at a temperature of 45°C and a pressure of 0.5 MPa, and control the pH of the reaction end point to 1.0. After the reaction, transfer the obtained leaching slurry into a plate and frame filter press for separation by filtration Obtain leachate and filter residue A3. After press filtration, dry the filter residue A3 with compressed air to reduce the water content of the filter residue A3 as much as possible. In order to improve the recovery rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com