High-temperature pyrolysis reactor and system and method for producing oil and carbon black by waste tire pyrolysis

A high-temperature pyrolysis, waste tire technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, special forms of dry distillation, etc., can solve the problems of complex fluidized bed process control, complex process flow, etc., to reduce costs and improve the reaction rate. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

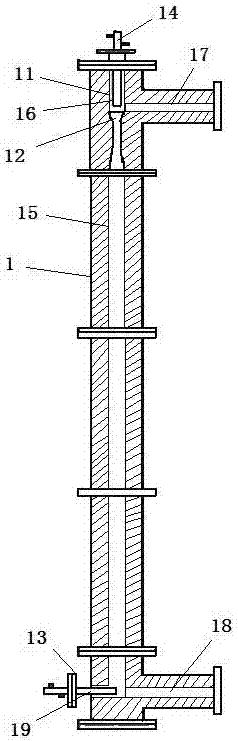

[0044] Such as figure 1As shown, the high-temperature pyrolysis reactor of the present invention includes a reactor body 1, a rubber powder nozzle 11, a mixer 12, a cooling device, and a rubber powder inlet pipe 14. The reactor body 1 is a straight tower body, and the reactor body 1 is provided with a rubber powder nozzle 11, a mixer 12, and a reaction pipeline 15 connected in sequence along its longitudinal direction; the rubber powder nozzle 11 is provided with a nozzle 16, and the nozzle 16 is aligned with the inlet of the mixer 12, and the outlet of the mixer 12 It communicates with the upper end of the reaction pipeline 15; the mixer 12 is a Venturi mixer; the lower end of the reaction pipeline 15 is provided with a cooling device 13 and an outlet pipe 17; Vertically extend into the reactor body 1, and its flue gas outlet is aligned with the outlet position of the nozzle 16; the top of the reactor body 1 is provided with a rubber powder inlet pipe 14, and the lower end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com