Preparation method of fluorine-containing branched sulfonated polyimide proton conducting membrane

A technology of sulfonated polyimide and proton conductive membrane, which is applied in circuits, electrical components, battery pack components, etc., can solve the problems of low resistance to vanadium, reduction, and weak oxidation resistance, and achieve strong oxidation resistance , high proton conductivity, and the effect of reducing vanadium permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

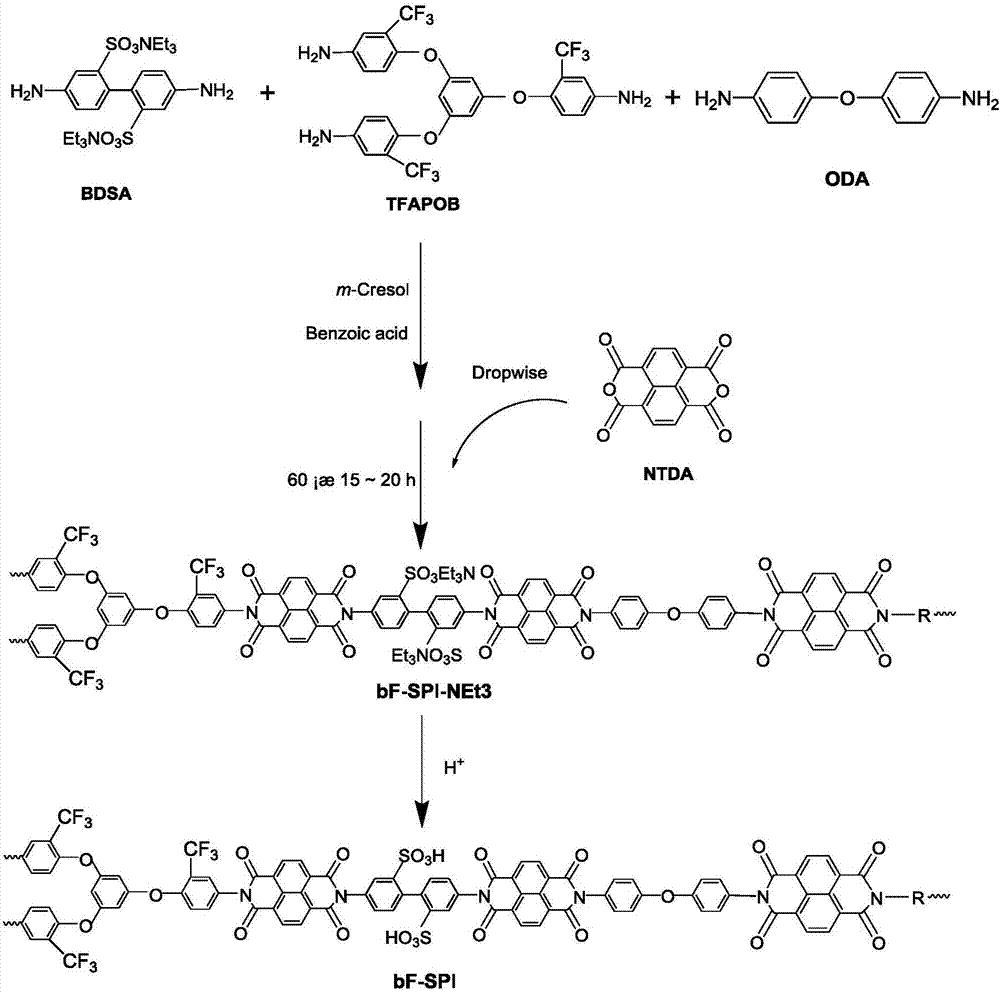

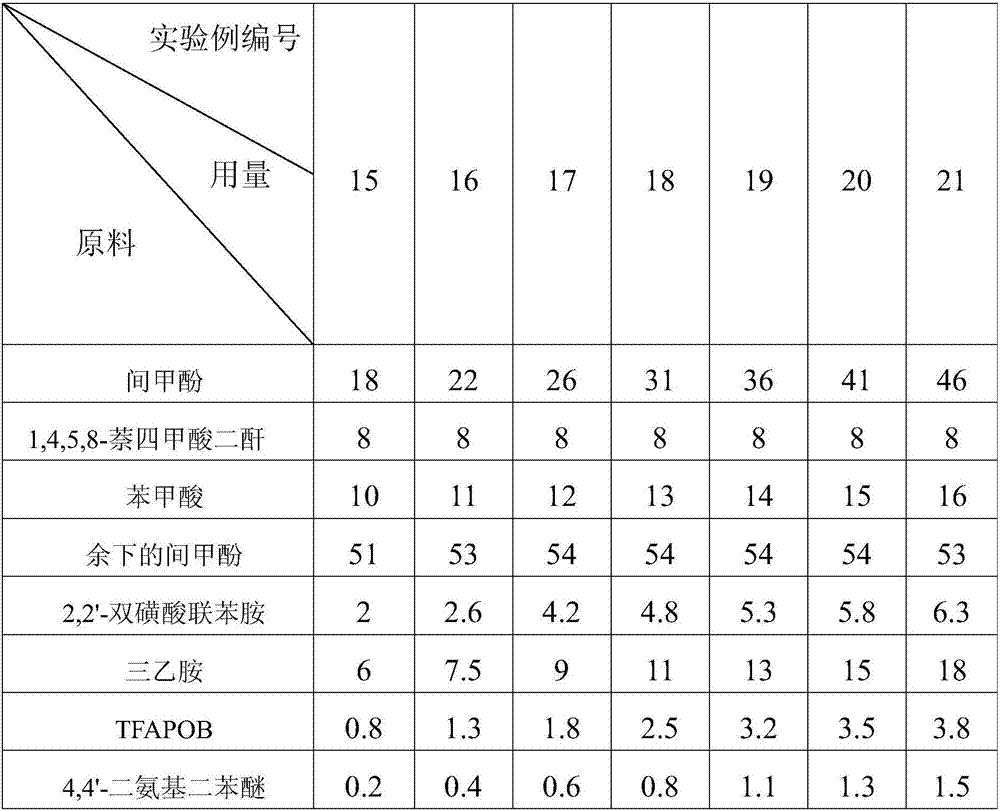

[0028] A preparation method for a fluorine-containing branched sulfonated polyimide proton conductive membrane, the steps of which are:

[0029] in N 2 Under protection, add 8.0mmol NTDA, 20mL m-cresol, and 9.8mmol benzoic acid into a 250mL three-neck flask, and stir continuously at room temperature until NTDA and benzoic acid are completely dissolved; dissolve 2.0mmol BDSA in a 50mL m- Add 5.0mmol triethylamine dropwise to cresol, wait until BDSA is completely dissolved, then add 1.0mmol ODA and 3.3mmol TFAPOB into the beaker to dissolve completely, and place it in a constant pressure dropping funnel and slowly drop it into a three-necked flask. And the temperature was raised to 60°C for 15 hours to obtain a film solution containing fluorine-branched SPI. The reaction solution was cast on a clean glass plate to form a film, and then dried at a temperature of 60-150°C for 20 hours (preferably a gradient , that is, the temperature is gradually increased in a gradient to dry), ...

Embodiment 2

[0034] A preparation method for a fluorine-containing branched sulfonated polyimide proton conductive membrane, the steps of which are:

[0035] in N 2 Under protection, add 8.0mmol NTDA, 30mL m-cresol, and 9.8mmol benzoic acid into a 250mL three-neck flask, and stir continuously at room temperature until NTDA and benzoic acid are completely dissolved; into cresol, and dropwise added 5.0mmol triethylamine, until BDSA was completely dissolved, then added 1.0mmol ODA and 2.67mmol TFAPOB into the beaker to dissolve completely, and placed in a constant pressure dropping funnel and slowly added dropwise into a three-neck flask, And the temperature was raised to 50°C for 20h to obtain a film solution containing fluorine-branched SPI. The reaction solution was cast on a clean glass plate to form a film, and then dried at a temperature of 60-150°C for 23h (preferably a gradient , that is, the temperature is gradually increased in a gradient to dry), that is, a triethylamine salt-type...

Embodiment 3

[0040] A preparation method for a fluorine-containing branched sulfonated polyimide proton conductive membrane, the steps of which are:

[0041] in N 2 Under protection, add 8.0mmol NTDA, 30mL m-cresol, and 14.7mmol benzoic acid into a 250mL three-neck flask, and stir continuously at room temperature until NTDA and benzoic acid are completely dissolved; dissolve 4.0mmol BDSA in a 70mL m- Add 5.0mmol triethylamine dropwise to cresol, wait until BDSA is completely dissolved, then add 2.0mmol ODA and 1.33mmol TFAPOB into the beaker to dissolve completely, and place it in a constant pressure dropping funnel and slowly drop it into a three-necked flask. And the temperature was raised to 50°C for 20h to obtain a film solution containing fluorine-branched SPI. The reaction solution was cast on a clean glass plate to form a film, and then dried at a temperature of 60-150°C for 25h (preferably a gradient , that is, the temperature is gradually increased in a gradient to dry), that is,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com