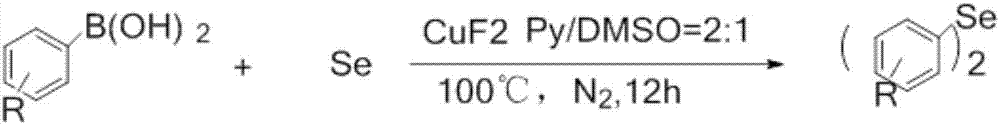

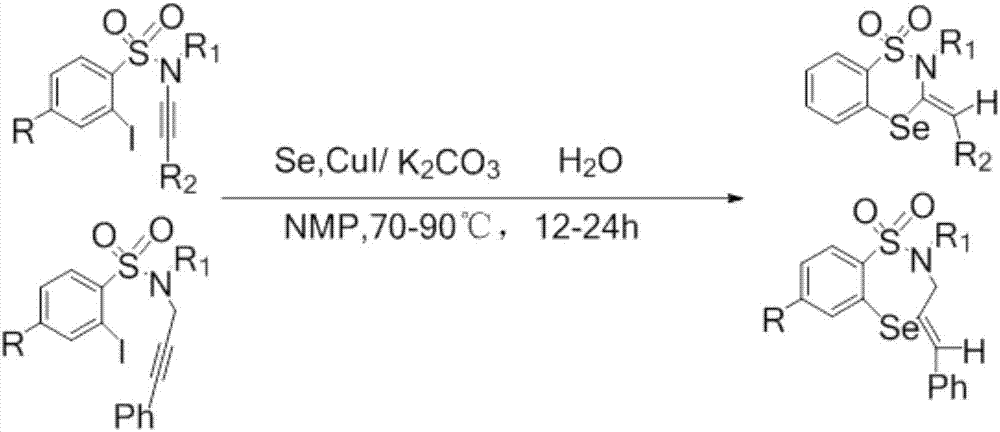

Preparation method of beta-hydroxyphenyl selenide compound

A hydroxyphenyl compound technology, applied in the field of organic compound synthesis, can solve problems such as poor substrate universality, and achieve the effects of simple operation, high yield and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] In the preparation method of the present invention, the reaction temperature is 100-140°C, for example, non-limitingly, 100°C, 110°C, 120°C or 140°C.

[0062] (7) Response time

[0063] In the preparation method of the present invention, the reaction time is not particularly limited. For example, the appropriate reaction time can be determined by liquid chromatography to detect the residual percentage of the target product or raw material, which is usually 2-30 hours, non-limitingly for example 2 hours, 4 hours, 6 hours, 8 hours, 10 hours, 12 hours, 14 hours, 26 hours, 28 hours or 30 hours.

[0064] (8) Separation and purification

[0065] The mixture obtained after the reaction can be further separated and purified to obtain a purer final product. Those of ordinary skill in the art are familiar with the methods of separation and purification, for example, methods such as extraction, column chromatography, distillation, decantation, filtration, centrifugation, washing...

Embodiment 1

[0069] Synthesis of 2-phenylselenylcyclohexanol

[0070]

[0071] At room temperature, aryl boronic acid (0.4mmol), selenium (1.2mmol, 3equiv), copper chloride (0.04mmol), silver nitrate (0.2mmol, 0.5equiv), reaction solvent 2mL DMSO were added to the reaction tube, at 120 Stir at the reaction temperature of ℃ for 12h; then add potassium tert-butoxide (0.8mmol, 2equiv) and ethylene oxide derivatives (1.2mmol, 3equiv) into the reaction tube, stir at the reaction temperature of 120℃ for another 12h, pass through a thin The end of the reaction was monitored by layer chromatography, and 2-phenylselenocyclohexanol was obtained after the end of the reaction.

[0072] Add 20mL of water and 10mL of ethyl acetate for extraction, then add anhydrous sodium sulfate to dry, filter after 5 minutes, wash the filter cake with ethyl acetate (5mL x 3 times), then spin off the solvent, and separate by column chromatography The product (eluent: petroleum ether: ethyl acetate = 6:1) was obtain...

Embodiment 2

[0078] Synthesis of 2-(4-methoxyphenylselenyl)cyclohexanol

[0079]

[0080] At room temperature, 4-methyl arylboronic acid (0.4mmol), selenium (2mmol, 5equiv), copper chloride (0.004mmol), silver nitrate (0.8mmol, 2equiv), reaction solvent 2mLDMSO were added in the reaction tube, in Stir at a reaction temperature of 100°C for 15h; then potassium tert-butoxide (0.2mmol, 0.5equiv) and ethylene oxide derivatives (2mmol, 5equiv) were added to the reaction tube, stirred at a reaction temperature of 100°C for another 15h, passed The end of the reaction was monitored by thin-layer chromatography to obtain 2-(4-methoxyphenylselenyl)cyclohexanol.

[0081] Add 20mL of water and 10mL of ethyl acetate for extraction, then add anhydrous sodium sulfate to dry, filter after 5 minutes, wash the filter cake with ethyl acetate (5mL x 3 times), then spin off the solvent, and separate by column chromatography The product (eluent: petroleum ether: ethyl acetate = 6:1) was obtained as a yellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com