Preparation method of 1,10-sebacic acid

A technology of sebacic acid and diketone, applied in the field of preparation of 1,10-sebacic acid, which can solve the problems of limited raw materials or sources, non-renewable petroleum resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

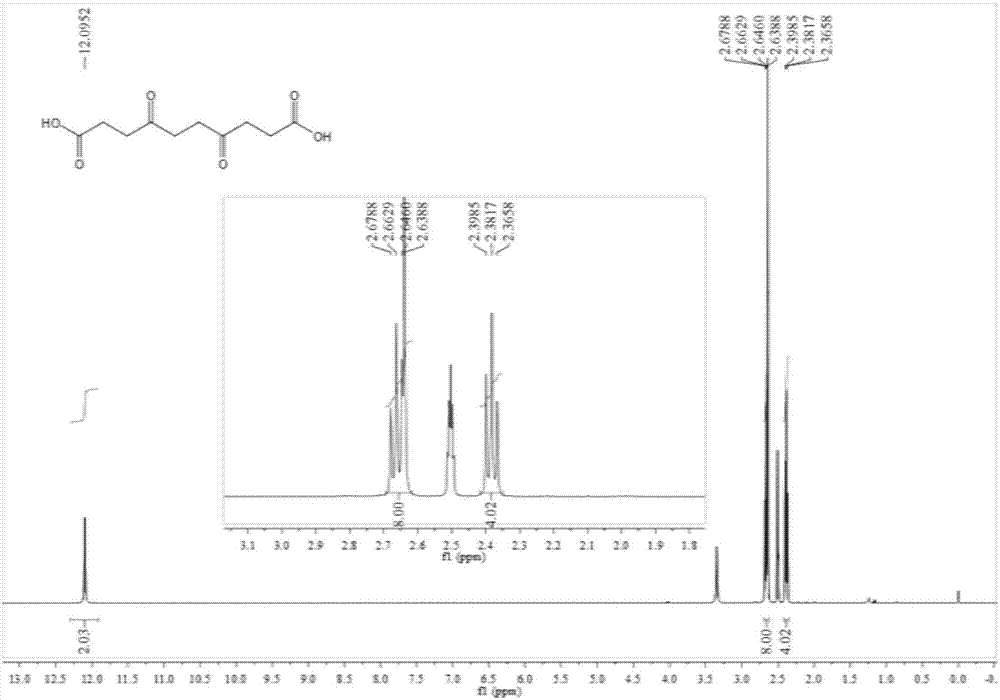

Image

Examples

Embodiment 1

[0074] A method for preparing 1,10-sebacic acid, comprising the steps of: hydrolyzing and ring-opening substance A in an acidic environment to obtain 4,7-diketone-1,10-sebacic acid; 4,7-diketone- Hydrodeoxygenation of 1,10-sebacic acid with hydrogen, trifluoromethanesulfonate, hydrogenation catalyst to obtain 1,10-sebacic acid

Embodiment 2

[0076] A method for preparing 1,10-sebacic acid, comprising the steps of: mixing methanol and methyl delta-furfuryl levulinate evenly, adjusting the pH to less than 1 with an aqueous solution of hydrochloric acid with a mass fraction of 37 wt%, refluxing for 17 hours, and spinning to dry Obtain a solid; dissolve the solid in an aqueous sodium hydroxide solution, add activated carbon to heat and decolorize, filter the filtrate, adjust the pH to less than 1 with hydrochloric acid, and crystallize to obtain 4,7-diketone-1,10-sebacic acid;

[0077] 4,7-diketone-1,10-sebacic acid, palladium on carbon, Al(OTf) 3 , acetic acid, and in a hydrogen atmosphere, adjust the hydrogen pressure to 80atm, stir and heat up to 140°C, keep stirring for 20h, filter the filtrate, and distill under reduced pressure to obtain a solid; dissolve the solid in aqueous sodium hydroxide solution, add activated carbon for decolorization, Take the filtrate by filtration, adjust the pH to less than 2 with hyd...

Embodiment 3

[0079] A preparation method of 1,10-sebacic acid, comprising the steps of:

[0080] Mix sodium hydroxide and levulinic acid aqueous solution, heat to reflux, add furfural methanol solution dropwise, reflux for 1 hour, acidify with 5wt% hydrochloric acid aqueous solution, filter to take filter cake, wash with ice water, and recrystallize in hot water to obtain δ -furfuryl levulinic acid, wherein the molar ratio of levulinic acid to furfural is 5:3, and the molar ratio of sodium hydroxide to levulinic acid is 1.05:1;

[0081] Mix methanol and δ-furfuryl levulinic acid evenly, adjust the pH to less than 1 with a 20 wt% hydrochloric acid aqueous solution, reflux for 10 hours, and spin dry to obtain a solid; dissolve the solid in a 10 wt% sodium hydroxide aqueous solution, add Activated carbon is heated for decolorization, and the filtrate is obtained by filtration, adjusted to pH less than 1 with hydrochloric acid, and crystallized to obtain 4,7-diketone-1,10-sebacic acid;

[008...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com