A method of calcium ion regulating biofilm method to treat low c/n ratio wastewater and quickly form a film

A biofilm method and calcium ion technology, which is applied in the field of calcium ion-regulated biofilm method to treat low C/N ratio wastewater with rapid film hanging, can solve the problems of inconvenient operation, difficult control, and need to monitor, and achieves easy operation and practicability. Strong and holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

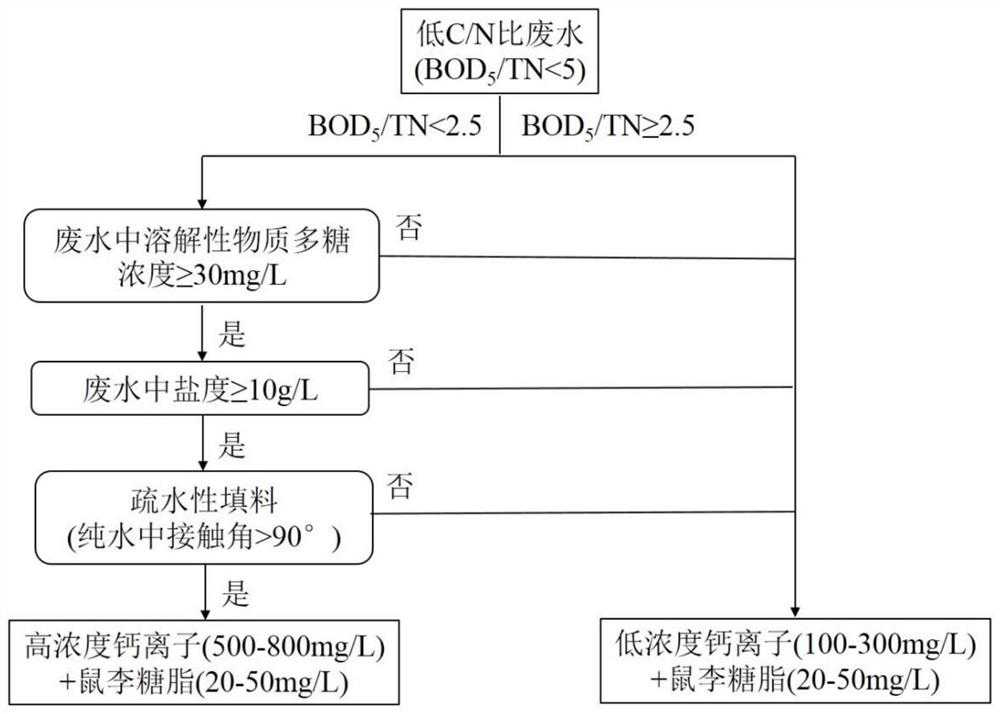

[0032] This example is about continuous flow moving bed biofilm reactor (MBBR) process BOD 5 Rapid film-forming method of organic fillers in the treatment of high-salinity wastewater with a / TN ratio of 1-2.5.

[0033] Waste water quality: BOD 5The concentration is 200mg / L, the TN concentration is 100mg / L, the salinity is 12g / L, and the soluble polysaccharide concentration in wastewater is 60mg / L. The suspended filler is made of polystyrene, and its pure water contact angle is 99.8 ± 2.23°, showing the characteristics of hydrophobicity. Its shape is a hollow cylinder, with a support structure inside and gears outside. The outer diameter and height of the filler are 25mm and 10mm respectively, and the density is about 0.95g / cm 3 , its effective specific surface area is about 460m 2 / m 3 .

[0034] According to the water quality and filler material conditions, the treatment plan of adding high-concentration calcium ions (800mg / L) supplemented with a certain concentration of...

Embodiment 2

[0043] This example is about the treatment of BOD by the continuous flow biofilm reactor method 5 A rapid film-forming method for organic fillers in the treatment of low-salinity wastewater with a / TN ratio of 2.5-5.

[0044] Waste water quality: BOD 5 The concentration is 500mg / L, the TN concentration is 150mg / L, the salinity is 500mg / L, and the soluble polysaccharide concentration in wastewater is 10mg / L. The suspension filler is made of polypropylene, and its pure water contact angle is 68.5 ± 1.52°, showing the characteristics of hydrophilicity. Its shape is spherical, and it is divided into inner and outer double-layer spheres. The outer part is a hollow fishnet-shaped sphere, and the inner part is a rotating sphere.

[0045] According to the water quality and filler material conditions, the treatment plan of adding low-concentration calcium ions (100mg / L) supplemented with a certain concentration of rhamnolipid (20mg / L) is selected, and at the same time, no calcium ions...

Embodiment 3

[0055] This example is about the biological aerated filter (BAF) treatment of BOD 5 A rapid film-forming method for organic fillers in the treatment of low-salinity wastewater with a / TN ratio of 2.5-5.

[0056] Waste water quality: BOD 5 The concentration is 500mg / L, the TN concentration is 150mg / L, the salinity is 400mg / L, and the soluble polysaccharide concentration in wastewater is 20mg / L. The carrier filler adopts clay ceramic particles.

[0057] According to relevant conditions, select to add low concentration calcium ion (100mg / L) and be supplemented with the processing scheme of rhamnolipid (30mg / L) of certain concentration, simultaneously with not adding calcium ion and adding high concentration calcium ion (800mg / L) L) The treatment regimen served as a control.

[0058] Its fast film-forming method is:

[0059] (1) Put the sludge taken from the aerobic tank of the municipal sewage treatment plant with a concentration of 3g / L into the BAF reactor, discharge all th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com