Heat-transfer-printing PET film ultraviolet-curing varnish and preparation method thereof

A technology of ultraviolet light and thermal transfer, which is applied in the field of coatings, can solve the problems of poor surface hardness of the coating film, high requirements for film forming equipment, and low production efficiency, and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

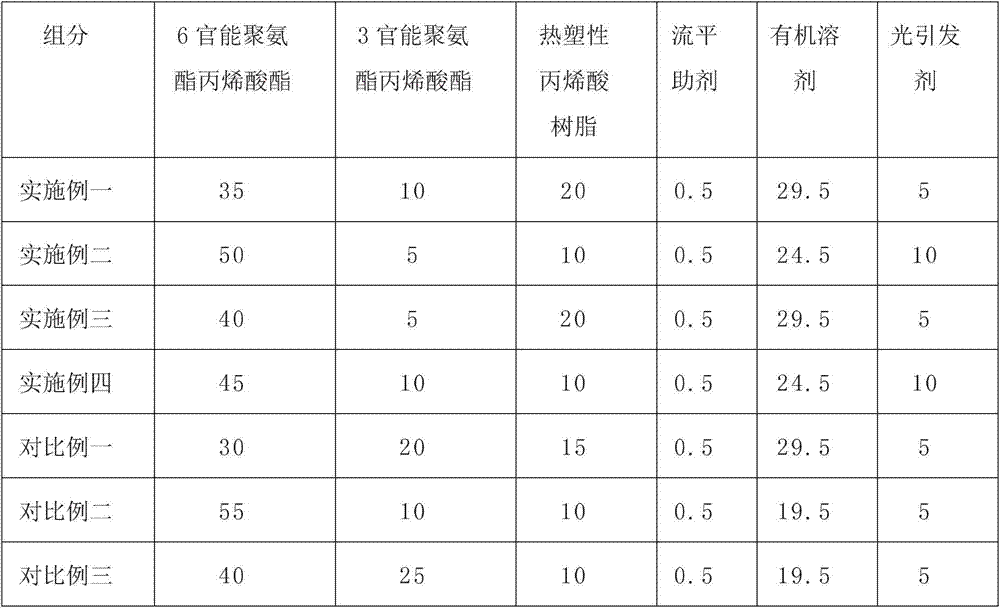

[0023] Embodiment 1: This embodiment provides a thermal transfer PET film UV-curable varnish, and the mass ratio of each raw material it includes is as follows:

[0024] 35% 6-functional urethane acrylate, 6-functional urethane acrylate can make the coating film have the advantages of fast response, good scratch resistance, good chemical resistance and good flexibility;

[0025] 10% 3-functional urethane acrylate, the combination of 3-functional urethane acrylate and 6-functional urethane acrylate can further increase the flexibility of the coating film;

[0026] Thermoplastic acrylic resin 20%, thermoplastic acrylic resin can reduce the curing shrinkage rate of the coating film, increase the adhesion of the coating film and the adhesion between the coating film layers, and improve the flexibility of the coating film;

[0027] Leveling aid 0.5%;

[0028] Organic solvent 29.5%;

[0029] Photoinitiator: 5%. The photoinitiator can cure the coating film with ultraviolet light ir...

Embodiment 2

[0030] Embodiment 2: This embodiment provides a thermal transfer PET film UV-curable varnish, the raw materials are the same as in Embodiment 1, and the mass percentages of the raw materials are: 50% of 6-functional urethane acrylate, 5% of 3-functional urethane acrylate, Thermoplastic acrylic resin 10%, leveling aid 0.5%, organic solvent 24.5%, photoinitiator: 10%.

Embodiment 3

[0031] Embodiment 3: This embodiment provides a thermal transfer PET film UV-curable varnish, the raw materials are the same as in Embodiment 1, and the mass percentages of the raw materials are: 40% of 6-functional urethane acrylate, 5% of 3-functional urethane acrylate, Thermoplastic acrylic resin 20%, leveling aid 0.5%, organic solvent 29.5%, photoinitiator: 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com