Device for producing BC (bacterial cellulose) composite

A technology of bacterial cellulose and composite materials, which is applied in the methods of biological material sampling, biochemical fiber processing, and biochemical cleaning devices, etc., can solve the problem of insufficient mechanical strength of wet bacterial cellulose, inability to cover gaps in gauze, uneven distribution, etc. problem, to achieve the effect of promoting rapid reproduction and producing cellulose, reducing labor intensity, and increasing production area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

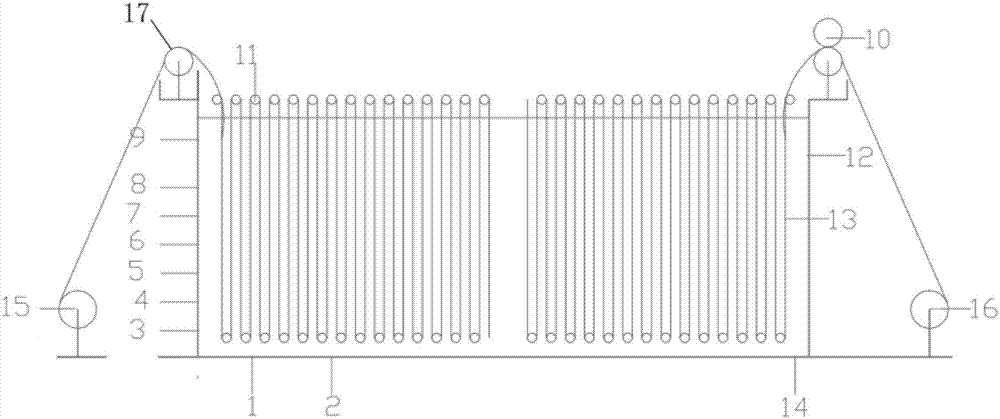

[0039] Such as Figure 1-3 As shown, the culture medium container 1 is an open rectangular parallelepiped container with a length of 200 meters, a width of 2 meters, and a height of 3 meters. The upper and lower rows of rolling shafts 11 in the container are parallel to each other with 1000, and the axis of the rolling shaft 11 is between the upper and lower The distance between the left and right rolling shafts 11 is 0.2 meters, and the roller diameter is 0.1 meters.

[0040] (1) Bacteria culture

[0041] Connect Acetobacter xylinum into 300mL liquid medium (per 1L of water, 400g glucose, 60g yeast extract, 100g tryptone, 1.15g citric acid, Na 2 HPO 4 2.7g, pH5.0, sterilized at 115°C for 30min) expansion culture, shaker culture at 30°C, 160r / min or static culture for 12h before use;

[0042] (2) Fermentation preparation of bacterial cellulose composite membrane

[0043] Using polyester fiber as the skeleton material 13, when using, the nutrient solution sterilized by high temperatur...

Embodiment 2

[0047] (1) Bacteria culture

[0048] The seed solution of Acetobacter xylinum was inserted into 300L of liquid culture medium (per 1L of water, 100g of maltose, 3g of peptone, and 5g of yeast extract, pH 4.5, and sterilization at 115°C for 30 min at 10% of the input amount; Or 160g fructose, 5g yeast extract, 5g tryptone, 1.15g citric acid, Na 2 HPO 4 2.7g, 1L water, pH5.0, sterilized at 115°C for 30min), the bioreactor is controlled at a constant temperature of 30°C;

[0049] (2) Fermentation preparation of bacterial cellulose composite membrane

[0050] Using calico as the skeleton material 13, transfer the liquid culture medium containing the production strain prepared in step (1) to figure 1 In the culture medium container 1 of the type, the frame material 13 is subjected to disturbance culture at a speed of 280m / h, and after dynamic culture at 30°C for 18 hours, the bacterial cellulose / cotton printed composite film can be obtained;

[0051] (3) Material handling

[0052] Remove t...

Embodiment 3

[0054] (1) Bacteria culture

[0055] The seed solution of Acetobacter xylinum was inserted into 300L of liquid culture medium (per 1L of water, 100g of maltose, 3g of peptone, and 5g of yeast extract, pH 4.5, and sterilization at 115°C for 30 min at 10% of the input amount; Or 160g fructose, 5g yeast extract, 5g tryptone, 1.15g citric acid, Na 2 HPO 4 2.7g, 1L water, pH5.0, sterilized at 115°C for 30min), the bioreactor is controlled at a constant temperature of 30°C;

[0056] (2) Fermentation preparation of bacterial cellulose composite membrane

[0057] Using medical gauze as the skeleton material 13, transfer the liquid medium containing the production strain prepared in step (1) to figure 1 In the type culture medium container 1, the skeleton material 13 is fermented at a vehicle speed of 104m / h for 48h to obtain a cellulose / gauze composite material;

[0058] (3) Material handling

[0059] Remove the prepared bacterial cellulose material from the collecting drum 16, rinse it with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com