Harmless recycling utilization system for kitchen oil fume and garbage

A resource-based, oil fume purifier technology, applied in the direction of oil fume removal, application, household stove, etc., can solve the problems of complex treatment process, increased resource waste, high operating cost, and achieve good safety, high recycling rate, and operating cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

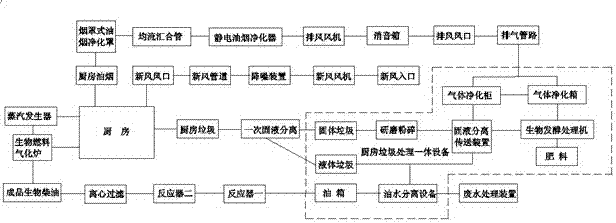

[0021] Such as figure 1 As shown, the kitchen cooking fume and garbage recycling system for harmless recycling provided by the present invention includes the following steps:

[0022] 1) The kitchen oil fume is sent to the electrostatic oil fume purifier through the hood-type fume purification hood and the uniform flow confluence pipe, and then sent to the exhaust air outlet through the exhaust fan and the silencer box. Further, the electrostatic oil fume purifier and the exhaust fan are also An activated carbon filter device can be installed to increase the oil fume removal rate to over 99%. Finally, the main component of the gas discharged through the exhaust outlet is carbon dioxide, which can be used as an important raw material for large-scale cultivation of seaweed with carbon dioxide. At the same time, fresh air passes through the fresh air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com