Preparation method of yellow warning garment material

A kind of clothing and yellow technology, which is applied in the field of preparation of yellow warning clothing fabrics, can solve the problems of poor visibility of reflective decorative materials, no warning effect, increase the physical and psychological burden of users, etc., achieve good moisture absorption and breathability, excellent durability The effect of washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of yellow warning clothing fabric of the present invention comprises the following steps:

[0025] (1), the preparation of fluorescent yellow powder:

[0026] Dissolve gadolinium oxide and dysprosium oxide in nitric acid respectively to obtain gadolinium nitrate solution and dysprosium nitrate solution; measure gadolinium nitrate solution and dysprosium nitrate solution and stir evenly; add urea and stir for 20 minutes, continue the reaction at 180°C for 12 hours, then cool to At room temperature, filter and wash with distilled water; dry the obtained product in a 70°C oven for 3 hours, then place it in a 900°C muffle furnace for calcination for 2 hours, and naturally cool to room temperature to obtain a fluorescent yellow powder sample;

[0027] Weigh a certain amount of silane coupling agent KH-570 and fluorescent yellow powder, fully hydrolyze in the water / ethanol solution with a pH value of 3.5-4.0, slowly add it to a round bottom flask,...

Embodiment 1

[0035] The preparation method is the same as the basic embodiment, the difference is: adjust the proportioning and preparation process of the fluorescent yellow powder in step (1), and detect the influence of the mass proportioning of the silane coupling agent and the fluorescent yellow powder on the relative fluorescence intensity, as shown in Table 1 Show.

[0036] Table 1. The effect of the mass ratio of silane coupling agent and fluorescent yellow powder on the relative fluorescence intensity

[0037] .

Embodiment 2

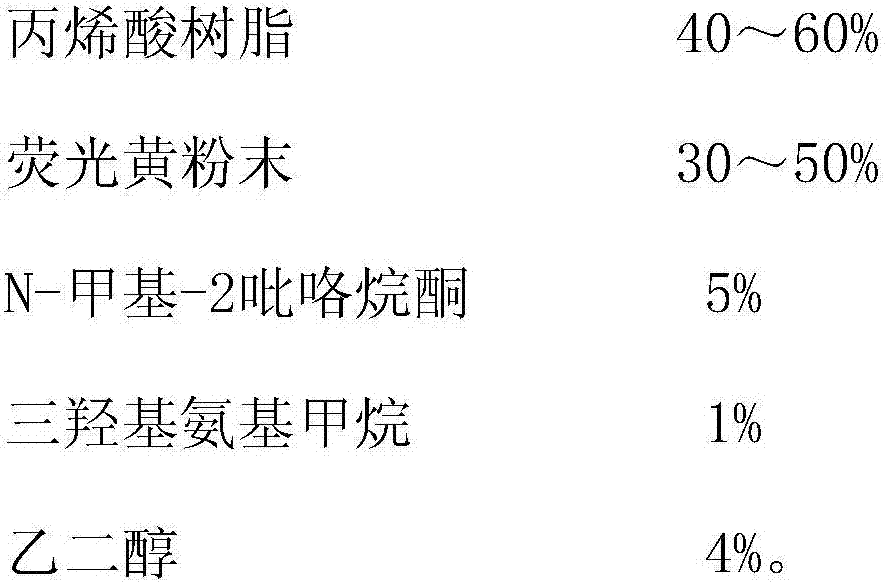

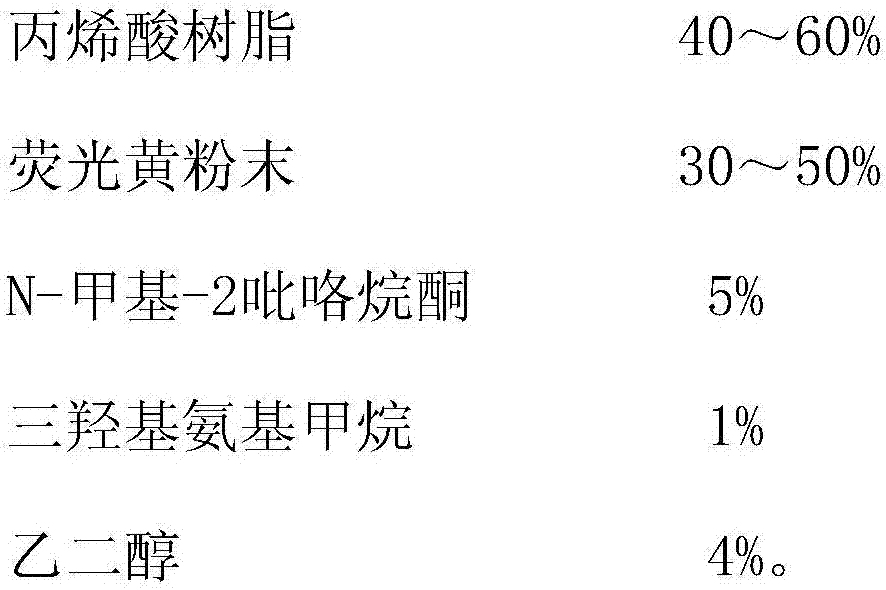

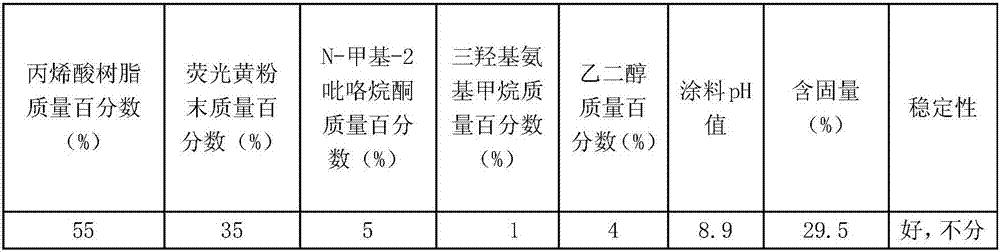

[0039] The preparation method is the same as the basic embodiment, the difference is: adjust the preparation process of step (2) fluorescent yellow paint, and detect the influence of acrylic resin and fluorescent yellow powder on the performance of fluorescent yellow paint, as shown in Table 2.

[0040] Table 2. Effect of acrylic resin and fluorescent yellow powder on the performance of fluorescent coatings

[0041]

[0042] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com