Phosphorus/nitrogen/sulfur synergistic flame retardant and application thereof in flame-retardant finishing of protein fiber products

A technology of synergistic flame retardant and protein fiber, which is applied in the direction of flame retardant fiber, fiber treatment, animal fiber, etc., can solve the problems that do not have guiding significance, and achieve mild reaction conditions, good washing resistance, and flame retardant efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

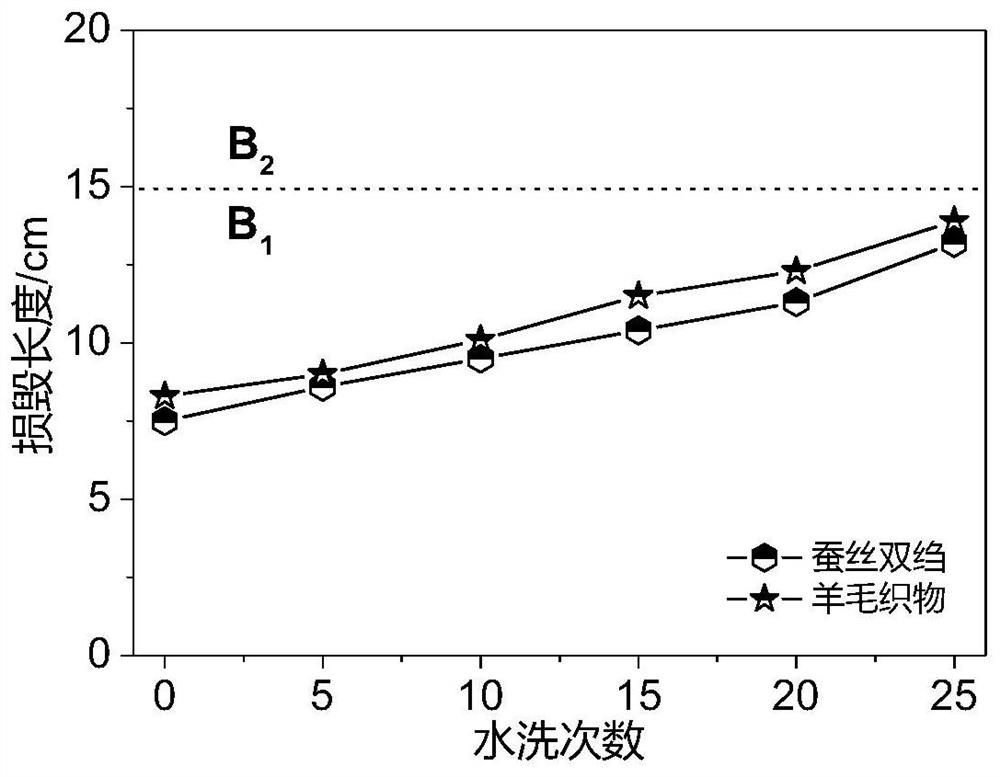

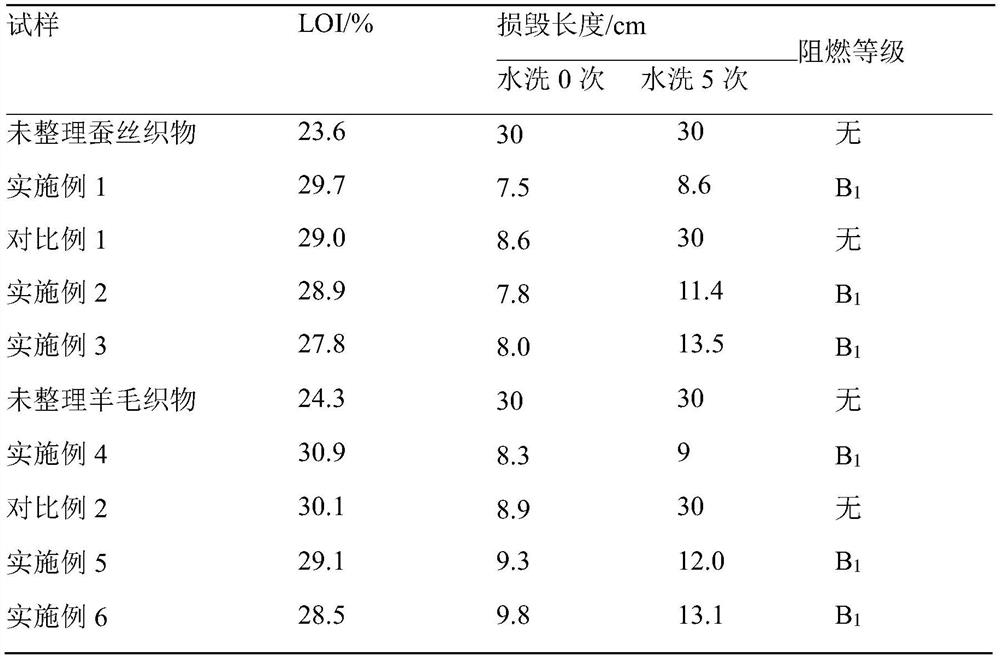

[0024] A method for preparing a phosphorus / nitrogen / sulfur synergistic flame retardant and a method for flame-retardant finishing silk crepe chine fabric, the specific steps are as follows:

[0025] (1) diethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of diethyl phosphite to ethanol is 14g:14mL;

[0026] (2) Add diethyl phosphite alcohol solution to glutaraldehyde and ammonium sulfamate solution and heat to 70°C, keep it warm for 60 minutes to obtain a flame retardant processing fluid; diethyl phosphite, ammonium sulfamate and glutamic acid The molar ratio of aldehyde is 2:2:2; the concentration of diethyl phosphite in the flame retardant processing fluid is 1mol / L;

[0027] (3) Immerse the silk crepe de Chine fabric in the flame-retardant processing solution, heat it to 70°C, and keep it warm for 60 minutes to obtain the flame-retardant silk crepe de Chine; the mass ratio of the silk crepe de Chine fabric to the fla...

Embodiment 2

[0031] A method for preparing a phosphorus / nitrogen / sulfur synergistic flame retardant and a method for flame-retardant finishing silk power textiles, the specific steps are as follows:

[0032] (1) Dimethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of dimethyl phosphite to ethanol is 6.9g:8mL;

[0033] (2) Add the dimethyl phosphite alcohol solution into the glyoxal and sulfamic acid solution and heat it to 80°C, and keep it warm for 40 minutes to obtain a flame-retardant processing fluid; The molar ratio is 2:2:1.5; the concentration of dimethyl phosphite in the flame retardant processing fluid is 0.5mol / L;

[0034] (3) Immerse the silk crepe de chine fabric in the flame-retardant processing solution, heat it to 80°C, and keep it warm for 50 minutes to obtain the flame-retardant silk electric spinning; the mass ratio of the silk electric textile fabric to the flame-retardant processing liquid is 1:40.

Embodiment 3

[0036] A method for preparing a phosphorus / nitrogen / sulfur synergistic flame retardant and a method for flame-retardant finishing silk crepe satin fabric, the specific steps are as follows:

[0037] (1) diethyl phosphite is dissolved in ethanol to obtain diethyl phosphite alcohol solution; the mass volume ratio of diethyl phosphite to ethanol is 2.8g:5mL;

[0038] (2) Add diethyl phosphite alcohol solution to malondialdehyde and sodium sulfamate solution and heat it to 60°C, keep it warm for 80 minutes to obtain a flame retardant processing fluid; diethyl phosphite, sodium sulfamate and propanediol The molar ratio of aldehyde is 2:2:1; the concentration of diethyl phosphite in the flame retardant processing fluid is 0.2mol / L;

[0039] (3) Immerse the silk crepe satin fabric in the flame-retardant processing liquid, heat it to 75°C, and keep it warm for 70 minutes to obtain the flame-retardant silk crepe satin; the mass ratio of the silk crepe satin fabric to the flame-retardan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com