Durable flame-retardant protein fiber product and preparation method thereof

A protein fiber, durable flame retardant technology, applied in the direction of flame retardant fiber, animal fiber, fiber treatment, etc., can solve the problems of complicated preparation method, long time consumption, poor washing resistance, etc., and achieve important practical application value and process. The effect of simplicity and good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

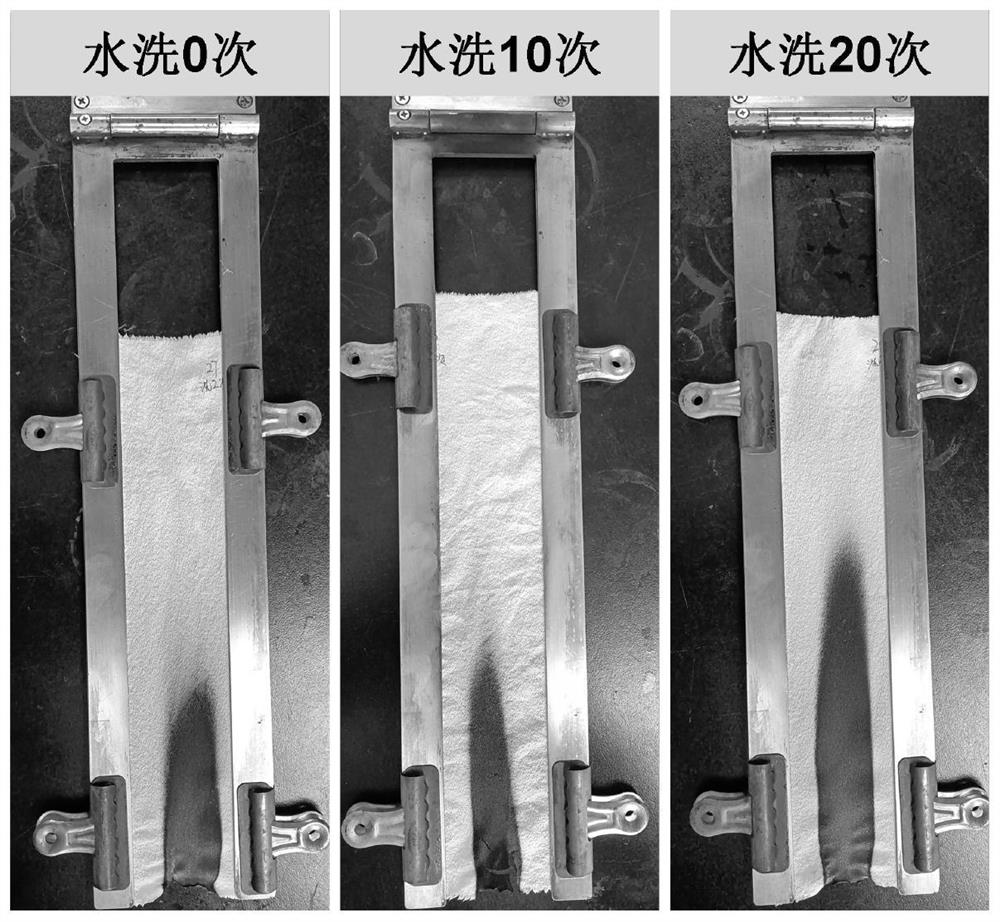

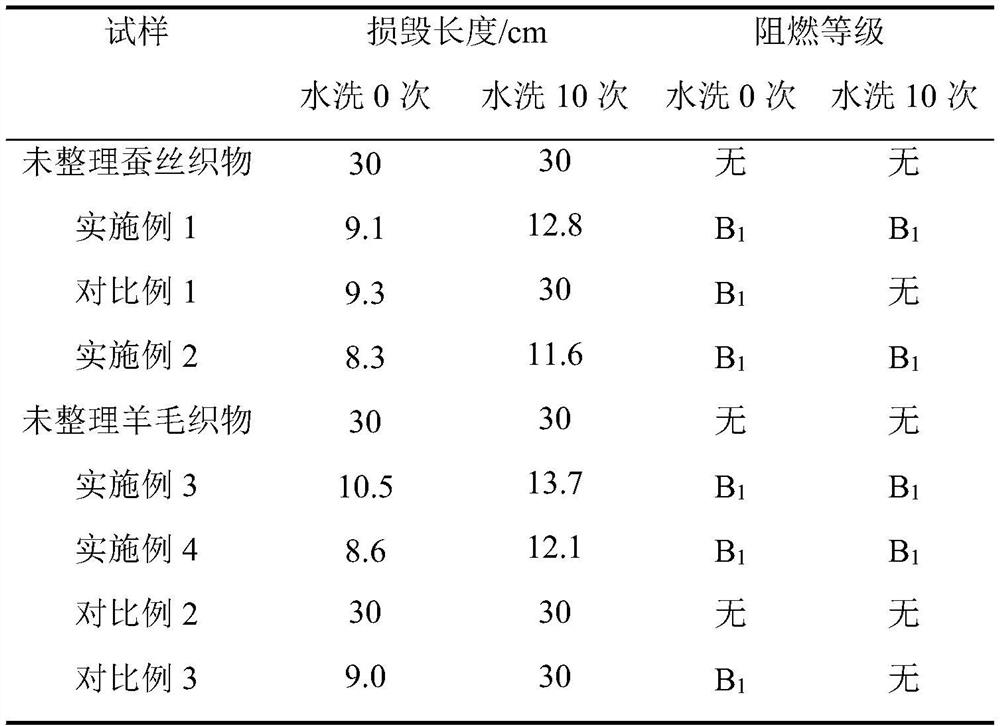

[0028] A durable flame-retardant silk crepe de chine fabric and a preparation method thereof, specifically comprising the following steps:

[0029] (1) phytic acid and p-Hydroxybenzaldehyde are dissolved in the mixed solution of distilled water and ethanol to obtain finishing solution, wherein the concentration of phytic acid is 100g / L, the concentration of p-Hydroxybenzaldehyde is 61g / L, p-Hydroxybenzaldehyde and The mass-to-volume ratio of ethanol is 1 g: 4 mL, and the silk crepe de chine fabric is put into the finishing solution, heated to 80°C, and kept for 60 minutes to obtain the finished silk crepe de chine fabric; the mass ratio of the silk crepe de chine fabric to the finishing solution is 1:40 .

[0030] (2) Immerse the above-mentioned finished silk crepe de chine fabric in an ethanol solution of 3-aminopropyltriethoxysilane, the molar ratio of 3-aminopropyltriethoxysilane and p-hydroxybenzaldehyde is 1:1, and the finishing The mass ratio of the silk crepe de chine ...

Embodiment 2

[0034] A durable flame-retardant silk fibroin crepe satin fabric and a preparation method thereof, specifically comprising the following steps:

[0035] (1) phytic acid and p-hydroxybenzaldehyde are dissolved in the mixed solution of distilled water and ethanol to obtain finishing solution, wherein the concentration of phytic acid is 150g / L, the concentration of p-hydroxybenzaldehyde is 100g / L, p-hydroxybenzaldehyde and The mass-to-volume ratio of alcohol is 1g:5mL, and the silk fibroin crepe satin fabric is put into the finishing solution, heated to 85°C, and kept for 50 minutes to obtain the finished silk fibroin crepe satin fabric; the mass ratio of the silk fibroin crepe satin fabric to the finishing solution is 1:30.

[0036] (2) The above-mentioned finishing silk fibroin crepe satin fabric is immersed in the ethanol solution of 3-aminopropyltrimethoxysilane, the molar ratio of 3-aminopropyltrimethoxysilane and p-hydroxybenzaldehyde is 1:1.2, and the silk is finished. Th...

Embodiment 3

[0038]A durable flame-retardant wool fabric and a preparation method thereof, specifically comprising the following steps:

[0039] (1) phytic acid and p-Hydroxybenzaldehyde are dissolved in the mixed solution of distilled water and ethanol to obtain finishing solution, wherein the concentration of phytic acid is 50g / L, the concentration of p-Hydroxybenzaldehyde is 50g / L, p-Hydroxybenzaldehyde and The mass-volume ratio of alcohol was 1g:3mL. The wool fabric was put into the finishing solution, heated to 95°C, and kept for 30 minutes to obtain the finished wool fabric; the mass ratio of the wool fabric to the finishing solution was 1:50.

[0040] (2) The above-mentioned finishing wool fabric is immersed in the ethanol solution of 3-aminopropylmethyldiethoxysilane, and the molar ratio of 3-aminopropylmethyldiethoxysilane to p-hydroxybenzaldehyde is 1:1.1 , the mass ratio of the finishing wool fabric to the ethanol solution of 3-aminopropylmethyldiethoxysilane is 1:50, and after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com