Anti-freezing low-temperature-resisting traffic marking material and preparation method thereof

A technology for traffic marking and low temperature resistance, applied in the field of transportation, can solve the problems of not meeting the needs of use, easy cracking and peeling, increasing traffic accidents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

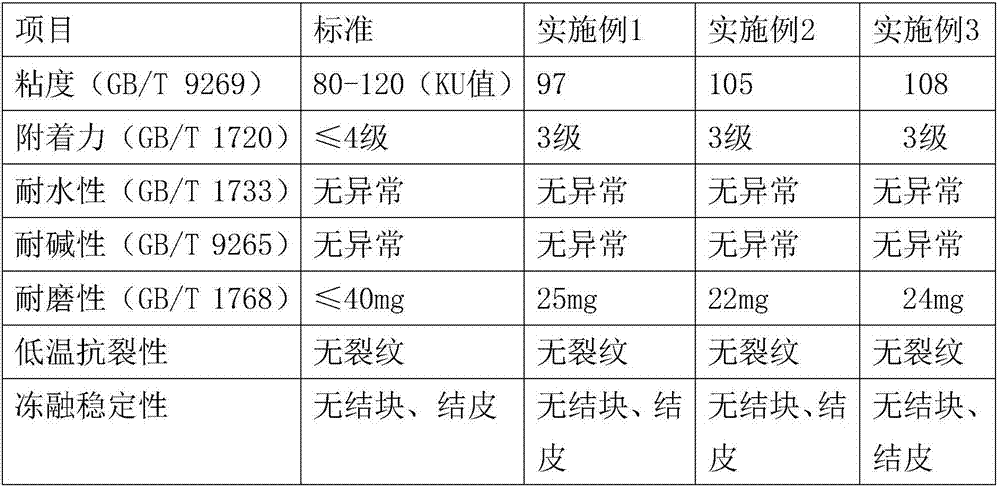

Examples

Embodiment 1

[0025] A wear-resistant and corrosion-resistant traffic marking material, comprising the following components in parts by mass:

[0026] 10 parts of polyester resin, 10 parts of rosin glyceride, 5 parts of polytetrafluoroethylene, 8 parts of parylene, 6 parts of modified polypropylene, 4 parts of quartz powder, 4 parts of glass beads, 1 part of tung oil, ethylene glycol 20 parts of glycol ether.

[0027] The particle size of the quartz powder is greater than 80 meshes, and the particle size of the glass microspheres is 100-150um.

[0028] Described modified polypropylene is made by following method:

[0029] The waste polypropylene material is cleaned and removed, and then passed through a crystallization drying tower to collect the dried polypropylene for use; the dried polypropylene is crushed and passed through a 30-40 mesh screen to obtain polypropylene powder; Put the polypropylene powder and EPDM rubber in the mass ratio into the mixer, stir at 200-300r / min for 30 minu...

Embodiment 2

[0039] An antifreeze and low temperature resistant traffic marking material, comprising the following components in parts by mass:

[0040] 18 parts of polyester resin, 18 parts of rosin glyceride, 15 parts of polytetrafluoroethylene, 14 parts of parylene, 10 parts of modified polypropylene, 5 parts of quartz powder, 5 parts of glass beads, 3 parts of tung oil, ethylene glycol 30 parts of glycol ether.

[0041] The particle size of the quartz powder is greater than 80 meshes, and the particle size of the glass microspheres is 100-150um.

[0042] The modified polypropylene is prepared by the following method: cleaning waste polypropylene materials to remove impurities, then passing through a crystallization drying tower, collecting the dried polypropylene for use; crushing the dried polypropylene, and passing through 30-40 Mesh sieve to obtain polypropylene powder; put polypropylene powder and EPDM rubber in the same mass ratio into a mixer, stir at 70-75°C for 30 minutes at a...

Embodiment 3

[0052] An antifreeze and low temperature resistant traffic marking material, comprising the following components in parts by mass:

[0053] 12 parts of polyester resin, 12 parts of rosin glyceride, 8 parts of polytetrafluoroethylene, 10 parts of parylene, 8 parts of modified polypropylene, 4 parts of quartz powder, 5 parts of glass beads, 2 parts of tung oil, ethylene glycol 25 parts of glycol ether.

[0054] The particle size of the quartz powder is greater than 80 meshes, and the particle size of the glass microspheres is 100-150um.

[0055] Described modified polypropylene is made by following method:

[0056] The waste polypropylene material is cleaned and removed, and then passed through a crystallization drying tower to collect the dried polypropylene for use; the dried polypropylene is crushed and passed through a 30-40 mesh screen to obtain polypropylene powder; Put the polypropylene powder and EPDM rubber in the mass ratio into the mixer, stir at 200-300r / min for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com