Diaphragm containing active interlayer, preparation method and application thereof

An active and interlayer technology, applied in the field of electrochemical energy storage, can solve the problems of limited inhibition of lithium dendrites, achieve the effects of inhibiting lithium dendrites, increasing discharge specific capacity, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

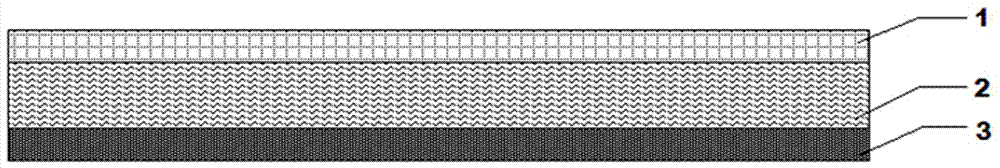

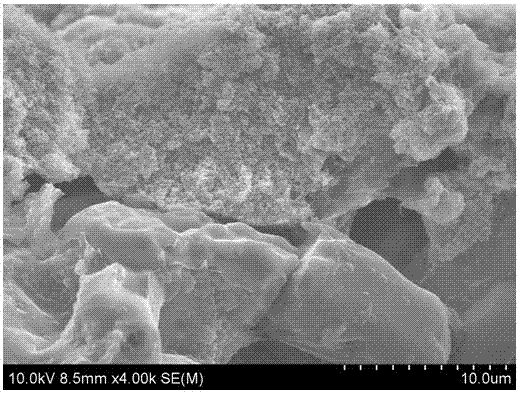

[0024] Weigh 0.1g of La132 into 30g of deionized water and stir with a magnetic stirrer until La132 is completely dissolved; weigh 1g of elemental sulfur into the La132 solution and stir for 2 hours to obtain a mixed active slurry. Squeegee-coat the active slurry on the polyethylene separator (as the base film), put it in a 60°C oven to dry, and form an active coating on the base film.

[0025] Weigh 0.1g CMC (sodium carboxymethylcellulose) into 30g deionized water, stir with a magnetic stirrer until CMC is completely dissolved; weigh 0.5g Al 2 o 3 Add PVDF (polyvinylidene fluoride) solution, stir for 3 hours, drop 2 drops of SBR (styrene-butadiene rubber) emulsion to obtain insulating slurry; spray the insulating slurry on the active coating, and put it in a 60°C oven to dry to form insulation layer, resulting in a membrane containing an active interlayer.

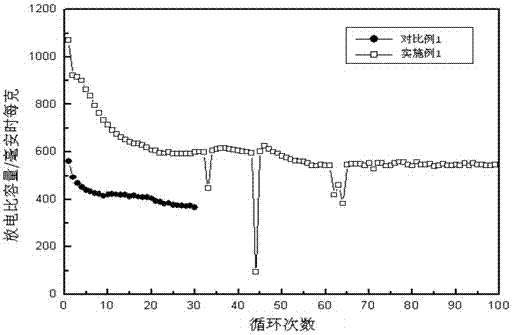

[0026] The lithium metal is used as the negative electrode, and the sulfur-carbon composite material is used as the p...

Embodiment 2

[0032] Weigh 0.01g of PVDF and add it to 30g of NMP (N-methylpyrrolidone), stir with a magnetic stirrer until the PVDF is completely dissolved; weigh 0.5g of carbon fluoride material into the PVDF solution, and stir for 6 hours to obtain a mixed active slurry. The active slurry is transferred and coated on the glass fiber membrane (base film), and dried in an oven at 100°C to obtain an active coating.

[0033] Weigh 0.05g PVDF, add 30g to NMP, stir with a magnetic stirrer until the PVDF is completely dissolved; weigh 0.1g silicate particles, add it to the PVDF solution, and stir for 3 hours; spray the insulating slurry on the active coating, put Oven-dried at 90°C to form an insulating layer on the active coating, thereby obtaining a separator containing an active interlayer.

[0034] The metal lithium is used as the negative electrode, and the carbon-sulfur composite material is used as the positive electrode, and the diaphragm containing the active interlayer prepared above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com