Solar energy tracking displacement platform used for sewage processing, and manufacturing method and application of solar energy tracking displacement platform

A technology of solar tracking and displacement platform, which is applied in the direction of using feedback control, measuring devices, instruments, etc., can solve the problems of easy aging of the structure, shortened maintenance cycle, unfavorable performance of solar tracking devices, etc., to reduce maintenance efficiency and improve The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a solar tracking displacement platform for sewage treatment, comprising the following steps:

[0038] Step 1: Add 2460 to 3670 parts of ultrapure water with a conductivity of 4.86μS / cm to 7.12μS / cm into the reactor, start the stirrer in the reactor at a speed of 117rpm to 183rpm, and start the heating pump to make the inside of the reactor The temperature rises to 122°C~185°C; add 3-methoxydopamine hydrochloride, 3-mercaptopropionic acid-2-ethyl-2-[(3-mercapto-1-oxopropoxy)methyl in sequence ]-1,3-propanediester, N-(4-hydroxy-3-methoxyphenylmethylene)-p-toluidine, stir until completely dissolved, adjust the pH value to 4.55~9.64, turn the stirrer speed Adjust to 185rpm~224rpm, the temperature is 181°C~242°C, and the esterification reaction takes 25~36 hours;

[0039] Step 2: Take 3-hydroxy-N-(4-methoxyphenyl)-4-(phenylazo)-2-naphthylcarboxamide, 3-hydroxy-4-[(2-methoxy-4 -Nitrophenyl)azo]-N-1-naphthyl-2-naphth...

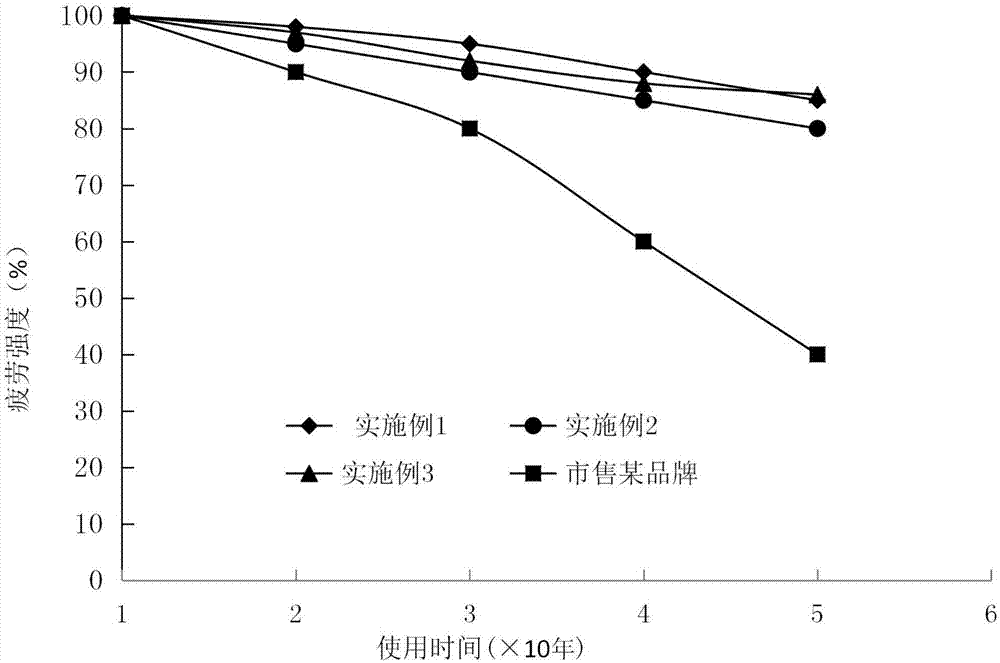

Embodiment 1

[0045] Prepare a displacement platform described in the present invention according to the following steps, and in parts by weight:

[0046] Step 1: Add 2460 parts of ultrapure water with a conductivity of 4.86μS / cm into the reactor, start the agitator in the reactor at a speed of 117rpm, start the heating pump, and raise the temperature in the reactor to 122°C; add in sequence 77 parts of 3-methoxydopamine hydrochloride, 2-ethyl-2-[(3-mercapto-1-oxopropoxy)methyl]-1,3-propanediate of 3-mercaptopropionic acid 138 parts, 162 parts of N-(4-hydroxyl-3-methoxyphenylmethylene)-p-toluidine, stir until completely dissolved, adjust the pH value to 4.55, adjust the stirrer speed to 185rpm, and the temperature is 181 ℃, esterification reaction for 25 hours;

[0047]Step 2: Take 119 parts of 3-hydroxy-N-(4-methoxyphenyl)-4-(phenylazo)-2-naphthylcarboxamide, 3-hydroxy-4-[(2-methoxy 91 parts of base-4-nitrophenyl)azo]-N-1-naphthyl-2-naphthylcarboxamide are pulverized, and the powder part...

Embodiment 2

[0052] Manufacture the displacement platform of the present invention according to the following steps, and in parts by weight:

[0053] Step 1: Add 3065 parts of ultrapure water with a conductivity of 5.99μS / cm into the reactor, start the stirrer in the reactor at a speed of 150rpm, start the heating pump, and raise the temperature in the reactor to 153°C; add in sequence 112 parts of 3-methoxydopamine hydrochloride, 2-ethyl-2-[(3-mercapto-1-oxopropoxy)methyl]-1,3-propanediate of 3-mercaptopropionic acid 190 parts, 227 parts of N-(4-hydroxy-3-methoxyphenylmethylene)-p-toluidine, stir until completely dissolved, adjust the pH value to 7.09, adjust the stirrer speed to 206rpm, and the temperature is 211 ℃, esterification reaction for 30 hours;

[0054] Step 2: Take 182 parts of 3-hydroxy-N-(4-methoxyphenyl)-4-(phenylazo)-2-naphthylcarboxamide, 3-hydroxy-4-[(2-methoxy 110 parts of base-4-nitrophenyl)azo]-N-1-naphthyl-2-naphthylcarboxamide are pulverized, and the powder particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com