Anti-ultraviolet aging modification method of polyester fiber

A technology of anti-ultraviolet aging and polyester fiber, which is applied in the direction of fiber treatment, fiber type, light-resistant fiber, etc., can solve the problems of polyester fiber damage, etc., achieve the effect of simple method, good application significance, and improved anti-ultraviolet aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

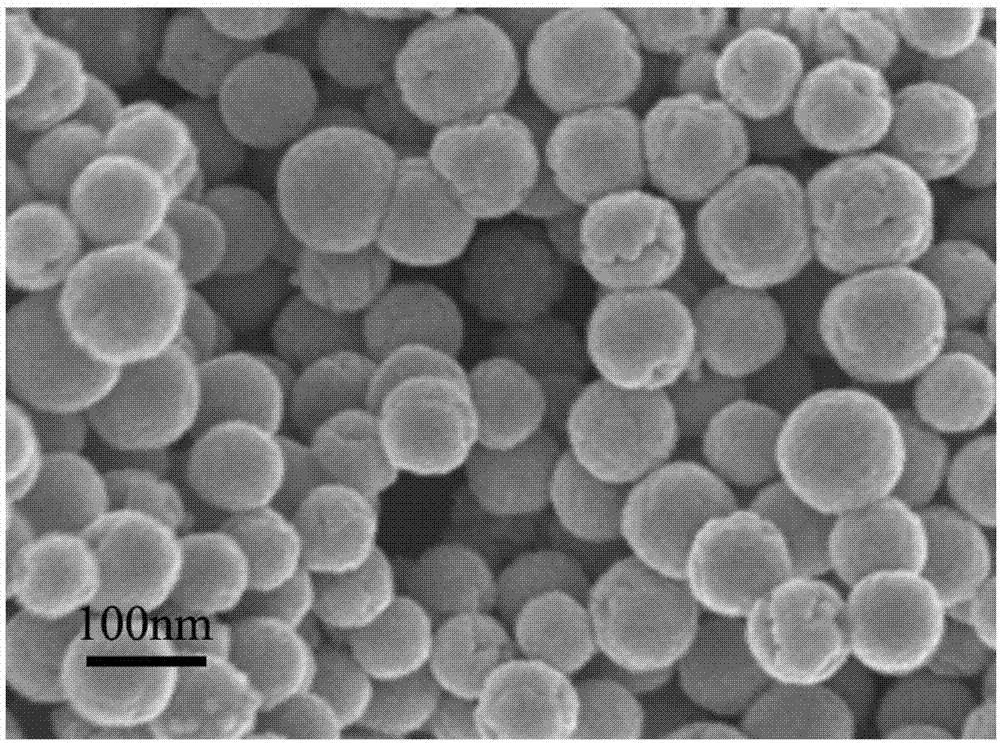

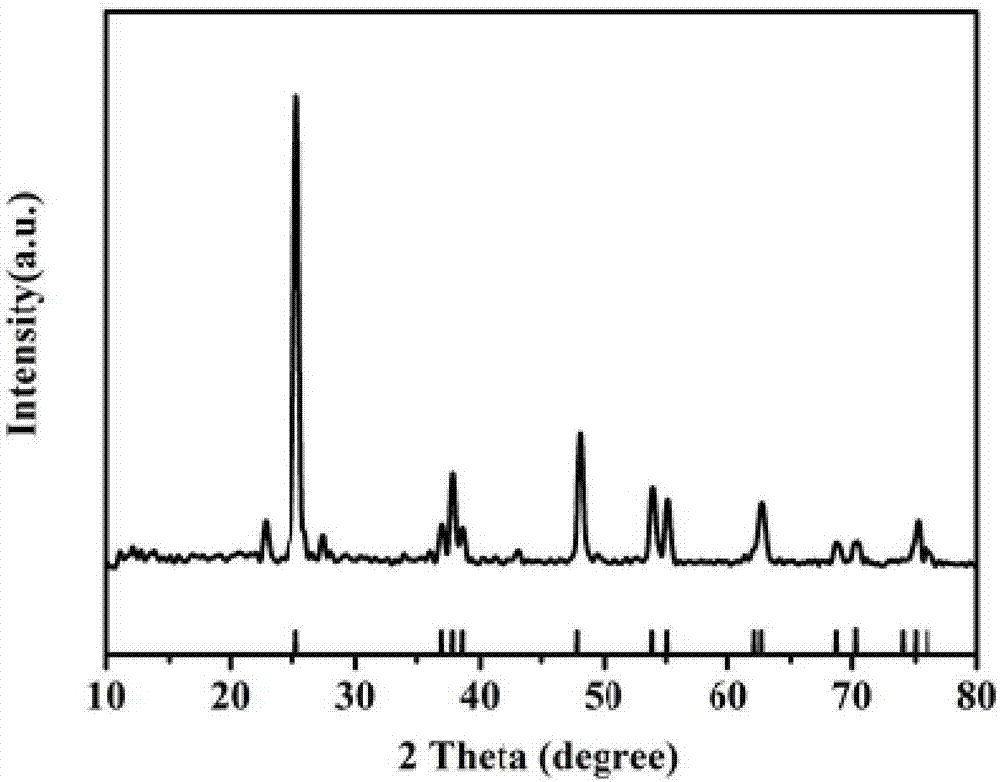

[0031] 1) In an anhydrous environment protected by nitrogen, 3 mL of tetrabutyl titanate was added to 150 mL of ethylene glycol, the mixed solution was stirred at room temperature for 8 hours, and then the mixture was poured into acetone containing 0.3% water by mass concentration In the solution, in the obtained mixed solution, the molar ratio of tetrabutyl titanate to acetone is 0.03M, and the mechanical stirrer is used to stir for 15min under the condition of 500r / min, and to stand for 1h to obtain nano-sized TiO 2 particles;

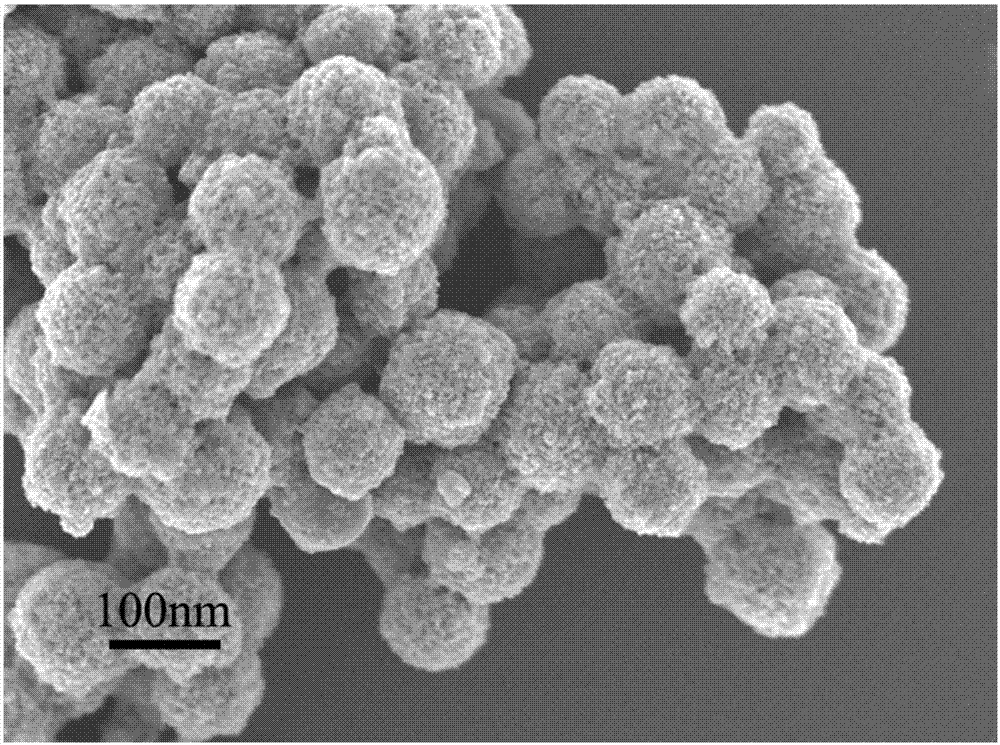

[0032] 2) the nano-scale TiO prepared in step 1) 2 Add 1 g of the particles into 50 mL of polyallylamine hydrochloride solution with a mass fraction of 1%, stir for 1 hour at 500 r / min with a mechanical stirrer, and centrifuge at 8000 r / min to obtain polyallylamine hydrochloride Salt coated TiO 2 particles;

[0033] 3) with the TiO obtained in step 2) 2 The particles were added to a polyacrylic acid solution with a mass fraction of 2%, stirred fo...

Embodiment 2

[0041] 1) In an anhydrous environment protected by nitrogen, 3 mL of isobutyl titanate was added to 150 mL of ethylene glycol, the mixed solution was stirred at room temperature for 8 hours, and then the mixture was poured into acetone containing 0.3% water by mass concentration In the solution, in the obtained mixed solution, the molar ratio of isobutyl titanate to acetone is 0.8M, and the mechanical stirrer is used to stir for 20min under the condition of 100r / min, and to stand for 1h to obtain nano-sized TiO 2 particles;

[0042] 2) the nano-scale TiO prepared in step 1) 2 Add 2 g of particles into 50 mL of a polyacrylimide solution with a mass fraction of 2%, stir with a mechanical stirrer at 100 r / min for 1 h, and centrifuge at 8000 r / min to obtain polyacrylimide-coated TiO 2 particles;

[0043] 3) with the TiO obtained in step 2) 2 The particles were added to a sodium polyacrylate solution with a mass fraction of 1%, stirred for 1 h with a mechanical stirrer at 100 r / ...

Embodiment 3

[0051] 1) In an anhydrous environment protected by nitrogen, 3 mL of tetramethyl titanate was added to 150 mL of ethylene glycol, the mixed solution was stirred at room temperature for 8 hours, and then the mixture was poured into acetone containing 0.3% water by mass concentration In the solution, in the obtained mixed solution, the molar ratio of tetramethyl titanate to acetone is 0.5M, and the mechanical stirrer is used to stir for 18min under the condition of 300r / min, and to stand for 1h to obtain nano-sized TiO 2 particles;

[0052] 2) the nano-scale TiO prepared in step 1) 2 Add 1.5g of granules into 50mL polyallylamine hydrochloride solution with a mass fraction of 1.5%, stir for 1h with a mechanical stirrer at 300r / min, and centrifuge at 8000r / min to obtain polyallylamine salt salt-coated TiO 2 particles;

[0053] 3) with the TiO obtained in step 2) 2 The particles were added to a sodium polystyrene sulfonate solution with a mass fraction of 1.5%, stirred with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com