Solar cell back electrode, solar cell and preparation method thereof

A technology for solar cells and back electrodes, applied in the field of solar cells, can solve the problems of uncontrollable deformation, increase in battery cost, uncontrollable deformation amount, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

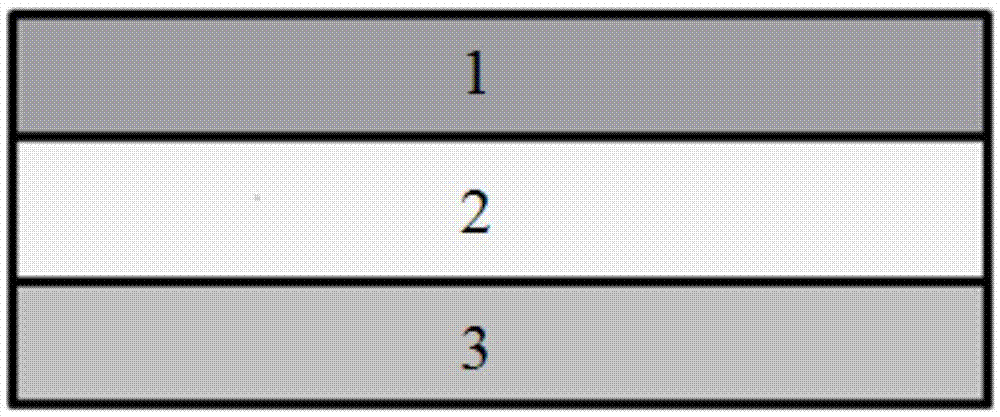

[0028] The preparation method of the solar cell back electrode provided by the present invention includes forming a bottom electrode on the non-tin surface of the glass substrate, wherein the method further includes forming a support layer on the tin surface of the glass substrate.

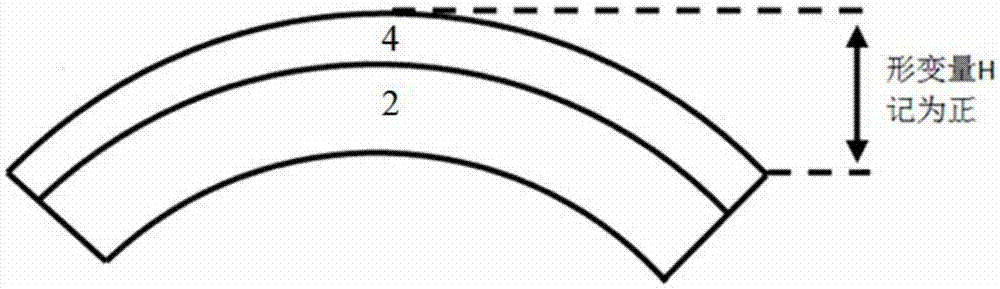

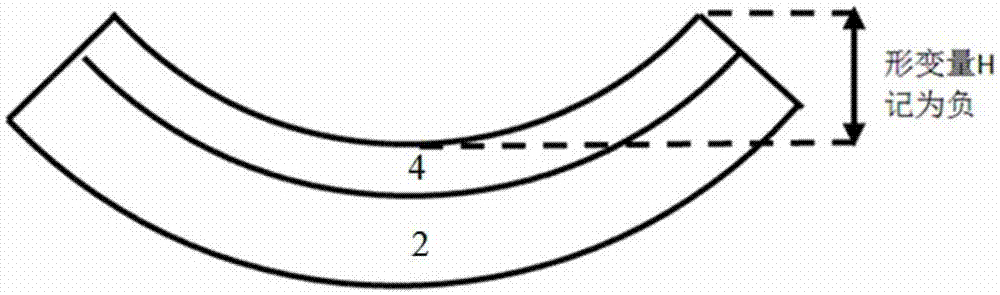

[0029] According to the present invention, as mentioned above, the support layer can adopt various existing methods that can effectively avoid the bending deformation caused by the decrease of the elastic modulus of the glass and the residual stress of the film under the subsequent high-temperature process (that is, it can effectively avoid the irreversible occurrence of the glass substrate. deformation), preferably at least one of a molybdenum layer, a chromium layer, a gold layer, a nickel layer, a platinum layer, a silver layer, a copper layer and a silicon oxide layer, more preferably a molybdenum layer, a chromium layer and a silicon oxide layer At least one of them is particularly preferably ...

Embodiment 1

[0060] This example is used to illustrate the solar cell back electrode provided by the present invention and its preparation method.

[0061] (1) Place the soda-lime glass substrate (size 5cm×5cm×3mm) into 10% by weight hydrochloric acid and ultrasonically clean it for 20 minutes, then take out the glass substrate and rinse it with deionized water to remove residual acid, then Place the glass substrate in absolute ethanol for 20 minutes, then take out the glass substrate, rinse it with deionized water to remove the residual ethanol liquid, then place the glass substrate in ultrapure water for 20 minutes, and clean the of glass substrates with N 2 Blow dry with an air gun and set aside.

[0062] (2) Use a tin surface meter to confirm the tin surface and non-tin surface of the soda-lime glass substrate. Then put the soda-lime glass substrate into the coating frame of the back electrode magnetron sputtering coating vacuum chamber, use metal molybdenum as the target material, a...

Embodiment 2

[0069] This example is used to illustrate the solar cell back electrode provided by the present invention and its preparation method.

[0070] (1) Same as Example 1.

[0071] (2) Use a tin surface meter to confirm the tin surface and non-tin surface of the soda-lime glass substrate. Then put the soda-lime glass substrate into the coating rack of the back electrode magnetron sputtering coating vacuum chamber, use metal molybdenum as the target material, and use the non-tin surface as the coating surface to perform DC magnetron sputtering on the non-tin surface of the glass substrate Molybdenum layer is formed. Specifically, draw a background vacuum to below 4.0E-4Pa, heat the glass substrate to 100°C, stop heating after 15 minutes, pass in argon gas of 30 sccm, adjust the air pressure to 0.8Pa by controlling the position of the cold pump plate valve, and start the glow And after 10 minutes of pre-sputtering, start to coat the first high-pressure layer for 600s; then adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com