Titanium nitride-based novel nano-structure photocathode

A nanostructure, titanium nitride technology, applied in nanotechnology for sensing, nano-optics, light-emitting cathode manufacturing, etc., can solve unfavorable electronic transition and tunneling emission, low external quantum efficiency of cathode, high material purchase cost, etc. problem, to achieve the effect of local electric field energy transmission, wide adjustable spectrum range, and improved probability and ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

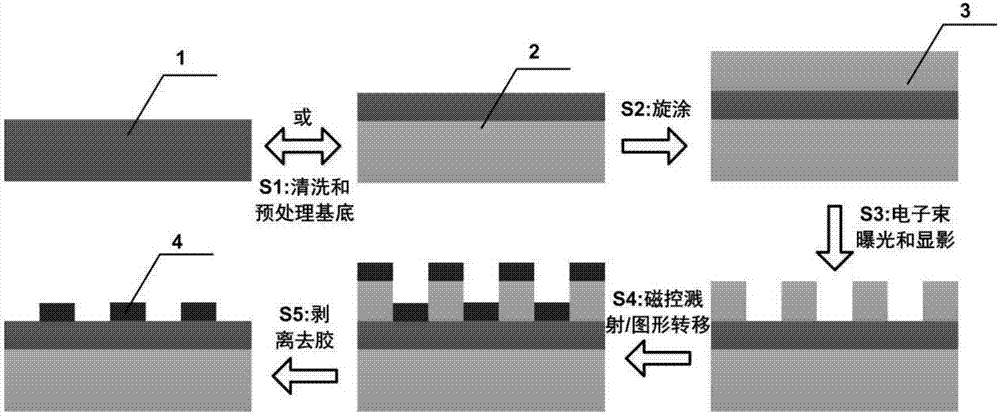

[0046] The present invention proposes a novel nanostructured photocathode and its preparation method, specifically, combining figure 1 As shown, the nanostructured photocathode of the present invention is prepared on a substrate material, such as a silicon wafer or a quartz substrate with a transparent conductive layer. Its concrete preparation method is as follows:

[0047] S1) process the base material:

[0048] For example, for quartz substrate materials, the surface is cleaned by ultrasonic cleaning with acetone, alcohol and deionized water in sequence, and then a transparent conductive oxide ITO thin film layer is prepared on the surface-cleaned quartz substrate material by magnetron sputtering. Specifically, for example, a 200 nm thick transparent conductive oxide ITO thin film layer is obtained by vapor deposition for 600 s under the condition of 100 W. The transparent conductive oxide of the present invention may also be fluorine-doped tin oxide (FTO) or aluminum-dop...

Embodiment 2

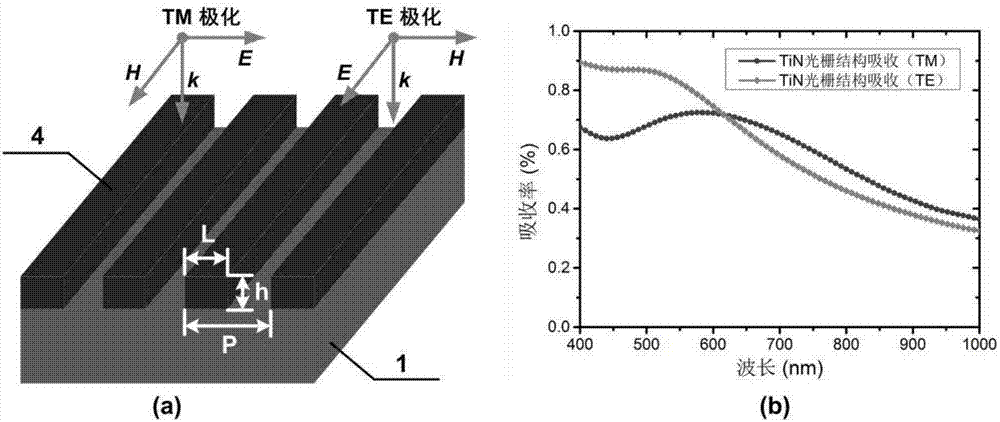

[0061] The invention discloses a photocathode based on a titanium nitride nano-grating structure, which combines figure 2 As shown, it adopts silicon chip as substrate 1, and the thickness of this substrate 1 is 500 μ m, adopts the method for embodiment 1 to prepare titanium nitride nano grating structure (sub-wavelength scale) on the surface then, and its width L is 150nm, and thickness h is 150nm, the period P is 300nm, and the duty cycle is 0.5. By solving the electromagnetic field, using the finite difference time domain (FDTD) method to simulate and simulate the absorption spectrum of the titanium nitride nanostructure layer in the present embodiment in the 400-1000nm band, as shown in the attached figure 2 As shown in (b), under the condition of TM (that is, the incident surface and the electric field direction perpendicular to the grating groove) polarized light irradiation, there is a resonant absorption peak at the light wave position of about 600nm, and the maximum...

Embodiment 3

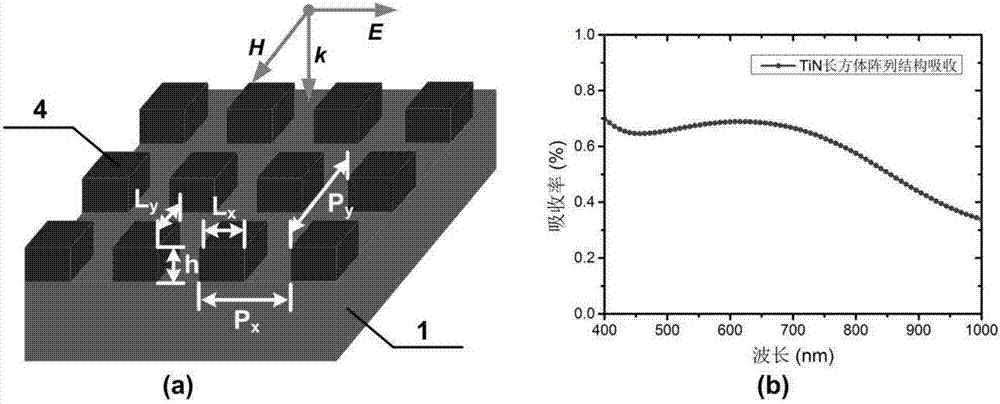

[0063] see image 3 , similar to Example 2, using the preparation process and method described in Example 1, the difference is that the titanium nitride nanostructure is a monodisperse nanostructure array, the width Lx and Ly are both 150nm, and the thickness h is 150nm. The period in the X-axis direction is 300nm, the duty ratio is 0.5, the period in the Y-axis direction is also 300nm, and the duty ratio is 0.5; the absorption of light waves by the titanium nitride nanostructure layer can be obtained by finite difference time domain simulation calculation situation, such as image 3 As shown in (b), there is a plasmon resonance absorption peak at about 650 nm, and the direction of the electric field E of the incident light wave vector is rotated by 90 degrees, and the obtained absorption spectrum is the same as image 3 It is exactly the same as shown in (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com