Wood-plastic composite floor board and preparation method thereof

A wood-plastic composite and floor technology, applied in the field of building materials, can solve the problems of easy cracking and poor bending performance, and achieve the effects of avoiding cracking, improving toughness and bending performance, and improving bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

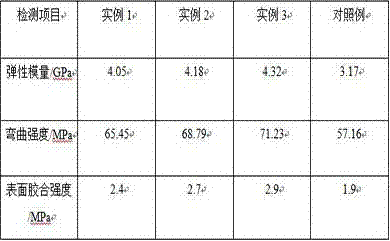

Examples

example 1

[0027]Take the rice husk, put it in an oven, and dry it at a temperature of 105°C until it reaches a constant weight to obtain dried rice husk, then crush it and pass it through a 100-mesh sieve to obtain rice husk powder, and transfer the obtained rice husk powder to a carbonization furnace , into the furnace at a rate of 80mL / min, under the protection of argon, keep warm and carbonize at 1100°C for 2 hours, cool down to room temperature with the furnace, and discharge the material to obtain carbonized rice husk, and then press the weight part Counting, 60 parts of carbonized rice husk, 80 parts of mass fraction of 20% hydrogen peroxide, and 60 parts of mass fraction of 20% nitric acid solution were stirred at a constant temperature for 2 hours at a temperature of 40 °C and a speed of 200 r / min. , to obtain a filter residue, and wash the obtained filter residue with deionized water until the washing solution is neutral, then dry the washed filter residue at a temperature of 85...

example 2

[0029] Take the rice husk, put it in an oven, and dry it at a temperature of 108°C until it reaches a constant weight to obtain dried rice husk, then crush it and pass it through a 150-mesh sieve to obtain rice husk powder, and transfer the obtained rice husk powder to a carbonization furnace , into the furnace at a rate of 100mL / min, and under the protection of argon, keep warm and carbonize at 1150°C for 3h, cool down to room temperature with the furnace, and discharge the material to obtain carbonized rice husk, and then press the weight part Counting, 70 parts of carbonized rice husk, 90 parts of mass fraction of 20% hydrogen peroxide, and 70 parts of mass fraction of 20% nitric acid solution were stirred at a constant temperature for 3 hours at a temperature of 45 °C and a speed of 300 r / min, and then filtered. , to obtain a filter residue, and wash the obtained filter residue with deionized water until the washing solution is neutral, then dry the washed filter residue at...

example 3

[0031] Take the rice husk, place it in an oven, and dry it at a temperature of 110°C until it reaches a constant weight to obtain dried rice husk, then crush it and pass it through a 200-mesh sieve to obtain rice husk powder, and transfer the obtained rice husk powder to a carbonization furnace , into the furnace at a rate of 120mL / min, under the protection of argon, keep warm and carbonize at a temperature of 1200°C for 4 hours, cool to room temperature with the furnace, and discharge the material to obtain carbonized rice husks, and then by weight Counting, 80 parts of carbonized rice husk, 100 parts of mass fraction of 20% hydrogen peroxide, and 80 parts of mass fraction of 20% nitric acid solution were stirred at a constant temperature for 4 hours at a temperature of 50 °C and a speed of 400 r / min, and then filtered. , to obtain a filter residue, and wash the obtained filter residue with deionized water until the washing solution is neutral, then dry the washed filter resid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com